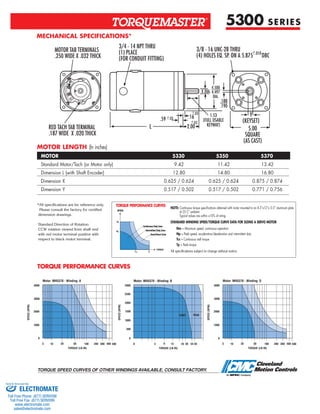

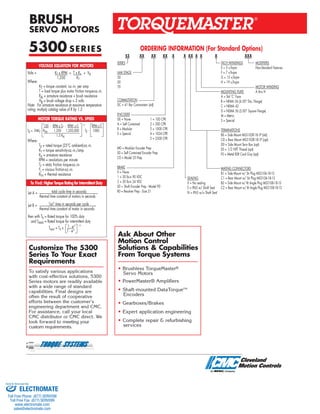

The document describes the Series 5300 brush DC servo motor. It provides high torque ratings, up to 48 lb-in of continuous torque and 350 lb-in of peak torque, for industrial applications. It has rugged construction, low cogging for smooth performance, and optional IP65 sealing. The motor is available in different winding configurations and customizations to meet application requirements.