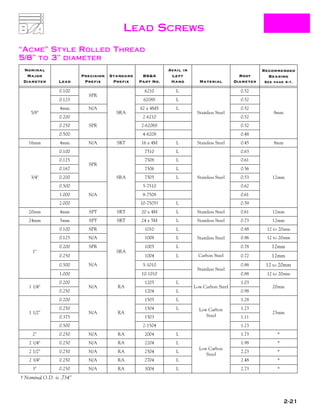

This document provides information on lead screws and supernuts from Ball Screws and Actuators. It discusses the features, advantages, design considerations and material properties of lead screws. Key points include that lead screws offer cost savings compared to ball screws, come in a variety of leads and diameters, and use stainless steel and internally lubricated acetal plastic for non-corrosive operation. Standard and precision grades are available with lead accuracies of 0.010 in/ft and 0.003 in/ft respectively. Load and temperature limits vary based on the specific assembly. Custom options are available to meet unique specifications.