The document provides details about the Tokyo Sky Tree project, including:

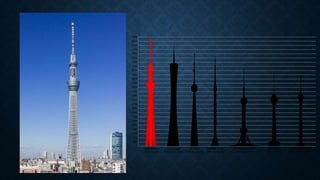

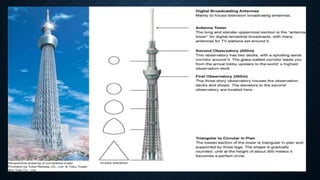

- It is a 634m tall broadcasting tower and restaurant in Sumida, Tokyo, built over 4 years at a cost of $800 million.

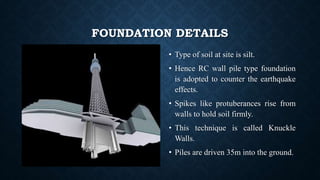

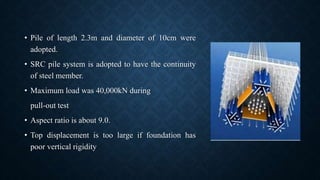

- The soil at the site is silt, so a reinforced concrete wall pile foundation was used, with knuckle walls and piles driven 35m into the ground, to withstand earthquakes up to magnitude 7.3.

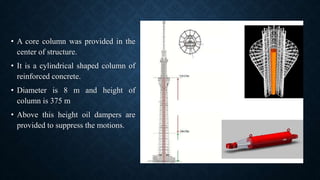

- Vibration control systems include two tuned mass dampers installed at 620m and 625m heights, as well as a core column with oil dampers above 375m, to suppress motions from wind.