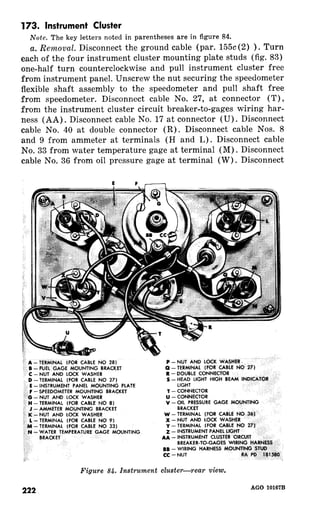

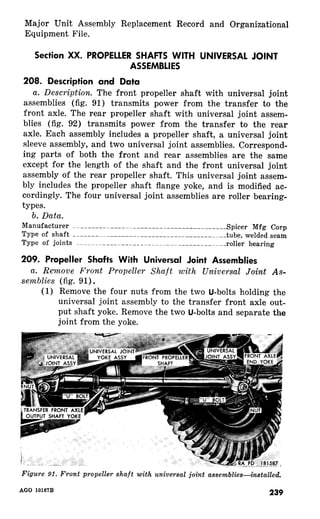

This document provides instructions for operating and maintaining the 1/4-ton 4x4 utility truck M38. It describes the major components of the vehicle, including the 4-cylinder gasoline engine, 3-speed transmission, 2-speed transfer case, front and rear axles, braking and electrical systems. The document outlines the organizational maintenance responsibilities and required reporting procedures for accidents, unsatisfactory equipment, or technical issues.

![Windshield wipers ____________________--___-__------ 100,266, 104,311,

266 312

Wiring circuits and cables___--_-__-_-__________-_-__ 163 212

[AG 451.2 (2 Sep 56)]

BY ORDER THE SECRETARIES OF THE ARMY

AND THE AIR FORCE:

OFFICIAL :

JOHN A. KLEIN,

MAXWELL D. TAYLOR,

F. TWINING,

OFFICIAL:

E. E. TORO,

Active Army:

CNGB (1)

Tee Svc, DA (1) except

COFOBD (25).

Ord Bd (2)

Hq, CONARC (3)

Army AA Comd (2)

OS Maj Comd (2)

OS Base Comd (2)

Log Comd (3)

MDW (1)

229R, 9-347R, 9-3673, 9-387R (1).

Ft & Cp (2)

Gen & Br Svc Sch (2) except Ord

Sch (SO).

PMST Ord ROTC Units (1)

Gen Depots (2) except Atlanta Gen

Armies (3)

Corps (2)

Div (2)

Brig (2)

Depot (None).

Ord Set, Gen Depots (5)

Ord Depot (10) except Rossford Ord

Depot (12)) Anniston Ord Depot

(16).

POE (2)

OS Sup Agencies (1)

Ord PG (10)

Regt Gp (1) except Ord

GP (2).

Bn (1) except Ord Bn (2)

except TOE: D-45R (1).

Ord Co (2) except TOE Q-

12R, 9-17R, 9-46R, B-

47R, 9-49R, 9-57R, 9-

ZVt3: State AG (6): units-same

one eopy to each unit.

USA R : None.

Ord Arsenal (5) except Raritan Ar-senal

(100)) Benicia Arsenal (20).

Mil Dist (1)

Ord Proc Diet (10)

MAAG (1)

Mil Men (1)

as Active Army except allowance is

For explanation of abbreviations used, see SR 326-50-l.

* U. S. Cov*mment Printing O&e: 1966-8677tO

AGO](https://image.slidesharecdn.com/tm9-8012-141030194747-conversion-gate01/85/TM-9-8012-322-320.jpg)