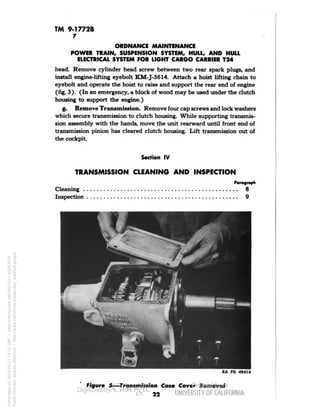

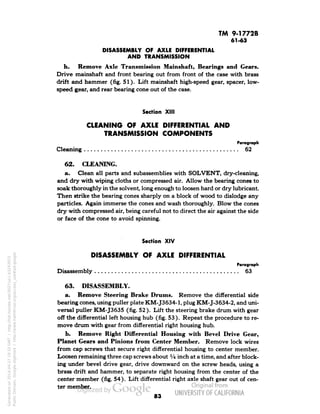

The document is a technical manual that provides instructions for maintenance and repair of the power train, suspension system, hull, and hull electrical system for the Light Cargo Carrier T24. It contains detailed procedures for removal, disassembly, inspection, and repair of these vehicle systems. The manual is divided into chapters that cover the transmission and propeller shaft, axle differential and transmission with final drives, suspension system, and hull and electrical systems.