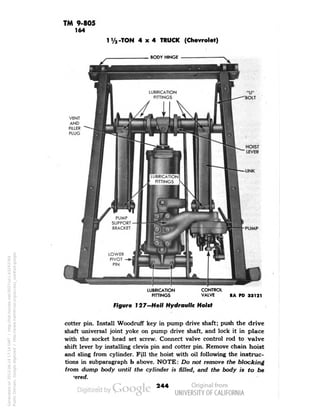

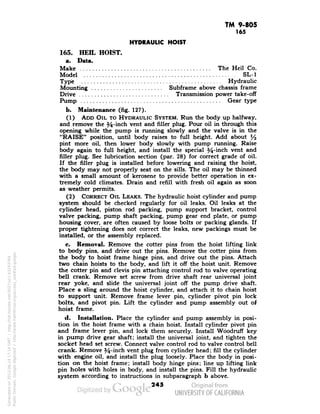

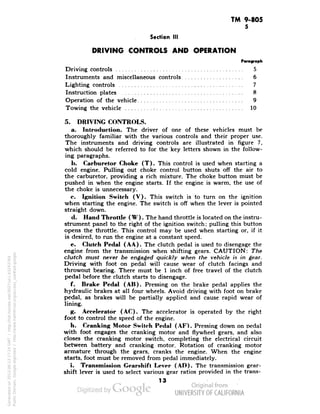

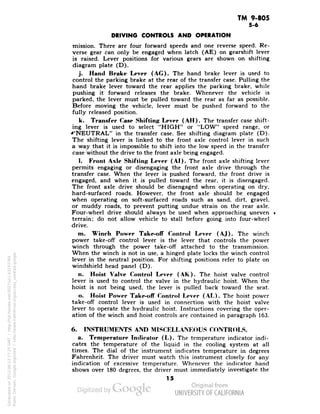

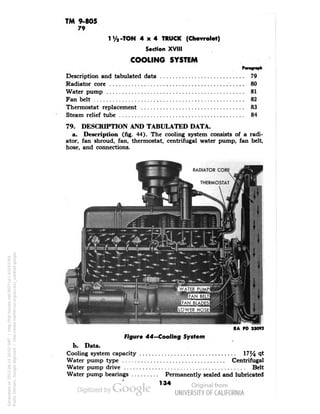

This document provides descriptions and technical data for several models of the 1 1/2-ton 4x4 Chevrolet truck used by the military between 1943-1945. It details the various configurations including chassis, cab, panel, dump, cargo, telephone, and specifications. The models share many core components but have specialized bodies and equipment tailored to their intended functions.

![WAR DEPARTMENT

Washington 25, D. C., 30 December 1943

TM 9-805—IVi-ton 4x4 Truck (Chevrolet), is published for the

information and guidance of all concerned.

[A. G. 300.7 (22Nov 43)]

BY ORDER OF THE SECRETARY OF WAR:

G. C. MARSHALL,

Chief of Staff.

OFFICIAL:

J. A. ULIO,

Major General,

The Adjutant General.

DISTRIBUTION: X.

(For explanation of symbols, see FM 21-6.)

Generated on 2013-06-13 17:16 GMT / http://hdl.handle.net/2027/uc1.b3243764

Public Domain, Google-digitized / http://www.hathitrust.org/access_use#pd-google](https://image.slidesharecdn.com/tm9-805-141108052035-conversion-gate02/85/TM-9-805-3-320.jpg)

![TM 9-805

28

LUBRICATION

1X1

in

M li

III 1

i^f

1!

$ S-2 »-£ S

z _. = -- « o

Will i

:2-!ill*3 i

*=i:;i!° .

!5i^iJ*i

0 *~ o -• i - '*

la ill til Ji

ill

I III ,d'O^

||Jl S£J|J

-ii Mils

I]

^"

1

1

"> *

Hi"' 111?4'

11

J^^-S n. > " » 2?

§•:'

l|JiJ Ji^l.

**Zsg KjK

« •

SJEe,B S-"'"

1

I

> Instruction

• and S»rvic« b»lo

iiu! m

if

II

i'S S • I **1 °

j= 8-fs i? is~:

h

!*• ^•"° ; <^rs ES-

•J] o

Jt

.{:t«:ii!^'

s» •

-3

vMHIslil!i

!+-;_

2 Van1

!1±1

1

•FLUID. br*lt. hyc

-FLUID. ihock-*b«

ft,

A

1!

pj

j

1

J

II

a.22 _•

jjSiC

S o a

I9ZZ

;=•

Generated on 2013-06-13 17:47 GMT / http://hdl.handle.net/2027/uc1.b3243764

Public Domain, Google-digitized / http://www.hathitrust.org/access_use#pd-google](https://image.slidesharecdn.com/tm9-805-141108052035-conversion-gate02/85/TM-9-805-46-320.jpg)

![TM 9-805

30

1V2-TON 4x4 TRUCK (Chevrolet)

Section VIII

TOOLS AND EQUIPMENT STOWAGE ON VEHICLE

Vehicle tools 30

Vehicle equipment 31

Vehicle spare parts 32

30. VEHICLE TOOLS.

a. General. Each vehicle is equipped with the tools listed in sub-paragraph

c below so that minor repairs can be performed by the

driving personnel. The larger tools, and a tool bag containing small

tools, are located on the several models as follows:

Model . Too) Location

G-7103—Chassis with cab Under driver's seat

G-7105—Panel In back of driver's seat back

G-7113—Cab tractor Tool box on right running board

G-7106—Dump less winch I TT

G-7116-Dump with winch f Under dnver s seat

G-7107—Cargo less winch I In compartment under body tail

G-7117—Cargo with winch f gate

G-7163—Telephone earth borer I TT ,

G-7173-Telephone maintenance f Under dnvers seat

b. Special Tools. A list of special tools for second echelon use

will be found in section XI.

c. Vehicular Tool List. , . ,, . ,,

„ . . .. Federal Stock No.

Crank, engine starting

Hammer, machinist's, ball peen, 16-oz 41-H-523

Handle, wheel bearing nut

Handle, wheel wrench

Pliers, combination slip joint, 6-in 41-P-1650

Screwdriver, clutch head, %2-in 41-S-1117-4

Screwdriver, clutch head, %-in 41-S-1117-6

Screwdriver, clutch head, y16-in 41-S-1117-8

Screwdriver, common, 6-in. blade 41-S-1104

Wrench, adjustable, automobile type, 11-in 41-W-448

Wrench, adjustable, crescent type, 8-in 41-W-486

Wrench, engineer's, open-end, %- x 7/16-in 41-W-991

Wrench, engineer's, open-end, l/2- x !%2-in 41-W-1003

Wrench, engineer's, open-end, %6- x ] Vie-in 41-W-1005-5

Wrench, engineers, open-end, %- x 2%2-in 41-W-1008-10

Wrench, engineer's, open-end, %- x %-in 41-W-1012-5

Wrench, spark plug

Wrench, special hex socket (winch trucks only)

Wrench, wheel

Wrench, wheel bearing nut

Wrench, clutch feed shaft coupling (earth borer only)

Wrench, clutch shaft bearing nut lock (earth borer only)

50

Generated on 2013-06-13 17:48 GMT / http://hdl.handle.net/2027/uc1.b3243764

Public Domain, Google-digitized / http://www.hathitrust.org/access_use#pd-google](https://image.slidesharecdn.com/tm9-805-141108052035-conversion-gate02/85/TM-9-805-49-320.jpg)

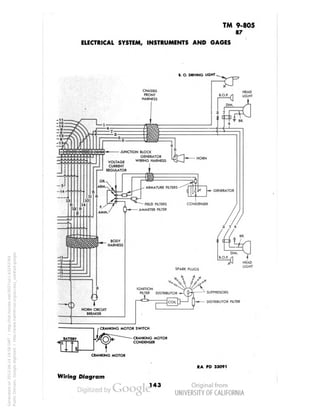

![TM 9-805

87

1 '/, -TO

N 4 x 4 TRUCK (Chevrolet)

*.!?* DOTTED LINES S

1 . ADDITIONAL CK

i USED ON

„ IX G-7113 MODELS

HOW CHASSIS

CUITS REAR HARNESS CHAS

G-7H3 MODELS REA

ONLY ONLY HARN

SIS

1

s-s. rii .

ss

S.T. V— 10-,

..O.T.L/a-1]

TRAILER

CONNECTOR , | |

B.K. S.

.^J~^f.^—i

10 fe^ £

t1"1

— M- 1 ne^ — /-I

^-194"

'Jit 9 — 1

| S G T| j

2 ~

'Xl? W"

PE

r— ^« _J

'S i

.s — ^

E!c

~T

3__ | —;

1 |3 DIMM

/TN SWITC

Generated on 2013-06-14 19:59 GMT / http://hdl.handle.net/2027/uc1.b3243764

Public Domain, Google-digitized / http://www.hathitrust.org/access_use#pd-google

:s^^

ML

-^4 —

L 1 BL*C

-*/Pf STOP'LAMP DRIVS'^

K-OUT x-x

-ia

3 LIGHT-— ( 3:

ITCH ^— ^

FUEL GAGE

TANK UNIT

V — / SWITCH

—6 '-•^>-

12

LOAD REGULATOR

DOME LIGHT

SWITCH

- ye:

I

J HORN BUTTON — »-(JD— 3—

— . TRAILER

BRAKE

CONTROLLER

DOME LIGHT-B.

O.T.[V 1 ,

•*p— S

• ^,8"l

"•asUr-^ o „ 8

FUEL GAGE "J (,

Jt

U-10-](https://image.slidesharecdn.com/tm9-805-141108052035-conversion-gate02/85/TM-9-805-141-320.jpg)

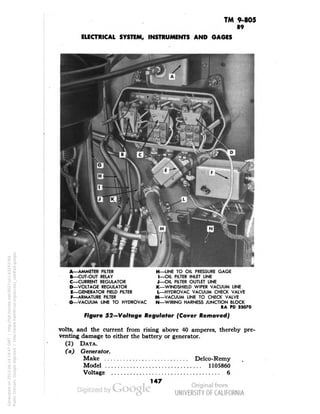

![TM 9-805

93

11/2-TON 4x4 TRUCK (Chevrolet)

CENTER LINE AHEAD-Lr

I nftlNU t«Mr v

~

^CENTER LINE

]/ OF TRUCK

SPOT SHOULD BE^

rEREDUPAND

N ON LINE A-A

r

^-CENTER LIN

/ OF RIGHT HX

^-HOT SPOT SHOULD

/ BE CENTERED SIDEWAYS

ON LINE B-B

I/

,^-HEADLAMP

/I

f////////,/fr,

- ^,"//i

>

~ •

S//////////<

s//, /'/'///,//

V

V| ,

3 FOR ALL

AIM RIGHT Ht

SAME AS LEF

CENTER HOT

LHOTSPO'

- OF HEADLAMP

SIDEWAYS O

UPPER E

EAM

NO FURTHER ADJU

STMENT IS

Generated on 2013-06-14 19:42 GMT / http://hdl.handle.net/2027/uc1.b3243764

Public Domain, Google-digitized / http://www.hathitrust.org/access_use#pd-google

NEEDED FOR LOW,ER BEAM

B

c

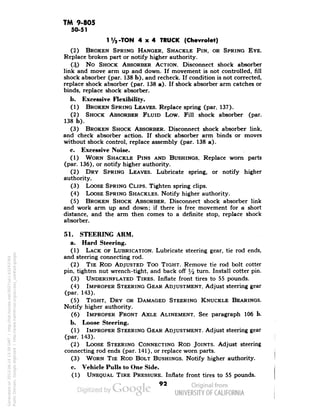

RA PD 32279

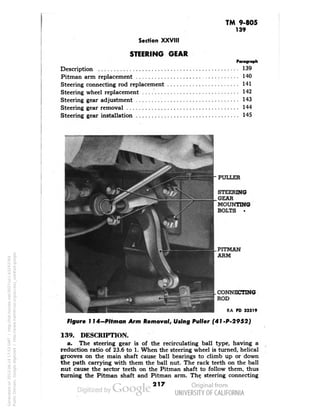

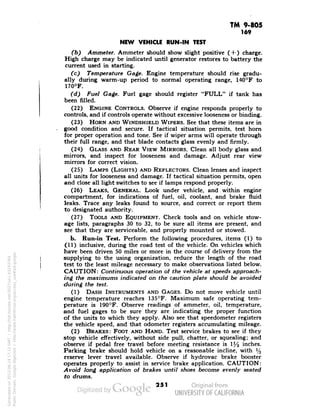

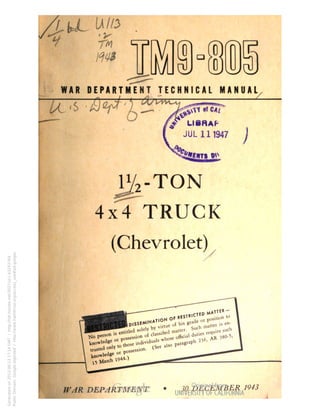

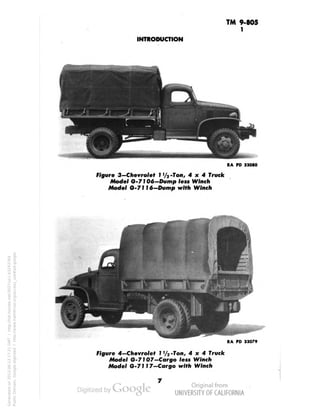

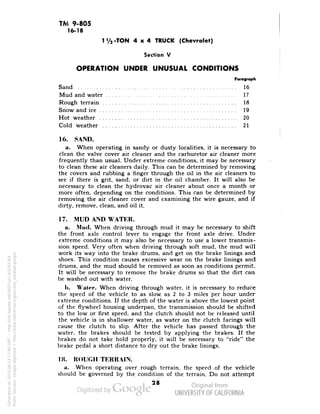

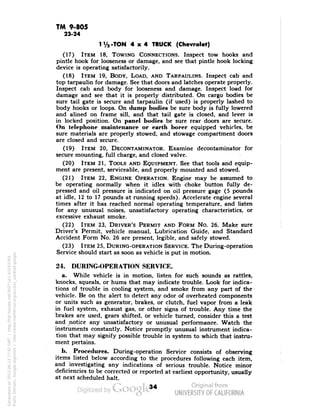

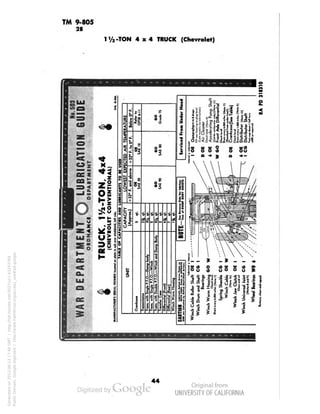

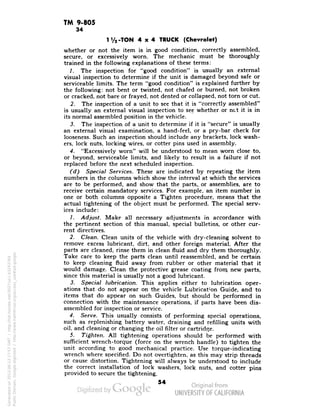

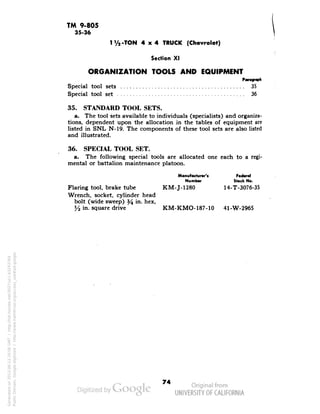

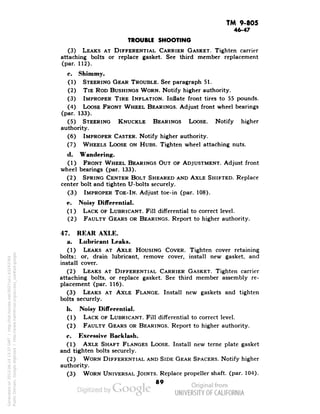

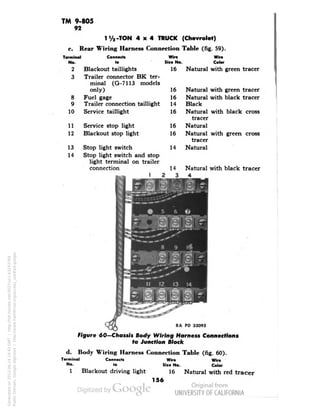

Figure 63—Headlight Aiming Diagram

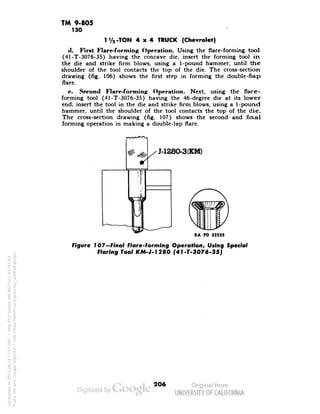

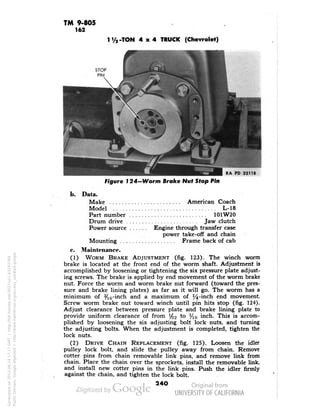

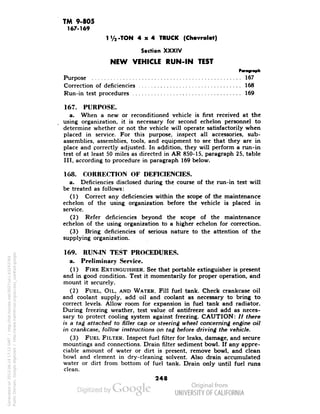

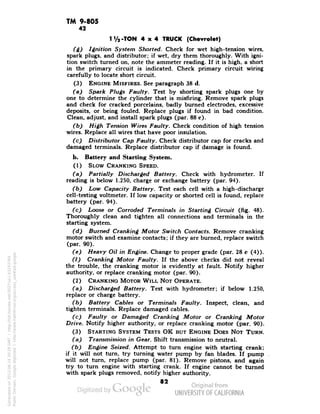

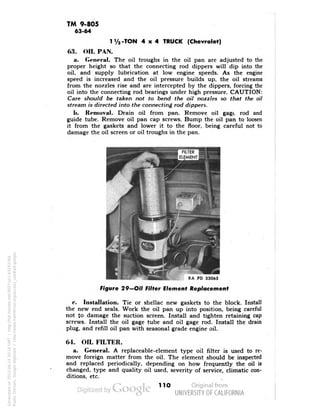

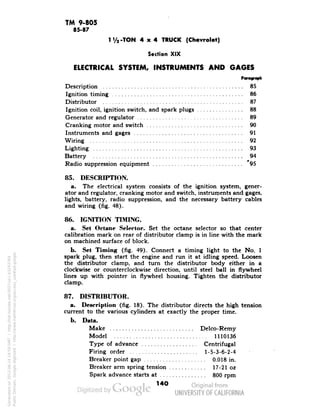

b. Headlight Aiming.

(1) INTRODUCTION (fig. 63). Headlights may be aimed by the use

of a portable aiming screen which can be constructed very easily.

Construct a frame approximately 5 feet high and 8 feet long. The

frame can be constructed of common lumber approximately 1 inch

x 3 inches. Cover the frame with a piece of light-colored cloth; make

a narrow, dark, vertical stripe down the center, and two stripes, 18

inches from each side of the center stripe and parallel to it, as shown

by lines "B" and "C" in the illustration. Then place nails on the end

upright of the frame so that the nails are 1 inch apart, beginning at

about 2 feet from the bottom of the screen and continuing upward

about 2 feet. Then secure a piece of black tape about yz- or 3^-inch

wide and about 6 inches longer than screen is wide. Fasten a weight

on each end of the tape to keep the tape stretched when laid across

the nails as shown by line "A" in the illustration.

(2) AIMING HEADLIGHTS. Place the screen against a wall in a

fairly dark corner of room that is fairly level. Run the vehicle directly

in front of the screen so that the headlights are 25 feet from the

screen. Measure from the floor to the center of the headlights, and

place the black tape across the screen so that it is 3 inches below

the center of the headlights. Turn on the upper beam of the head-lights,

and cover one of the lights. Check the location of the beam

on the screen. The center of the hot spot should be centered on the

intersection of the vertical and horizontal lines as shown in figure 63.

If the aim is incorrect, loosen the nut on the headlight mounting

bolt, and move the headlight body on its ball and socket joint until](https://image.slidesharecdn.com/tm9-805-141108052035-conversion-gate02/85/TM-9-805-159-320.jpg)

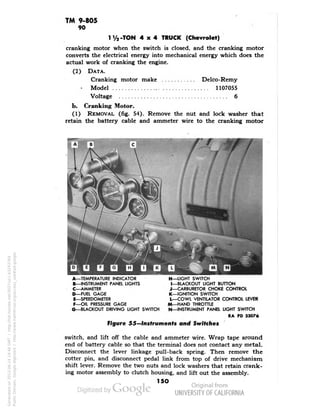

![TM 9-805

110-111

1 Va -TON 4x4 TRUCK (Chevrolet)

TA|NERGASKET

OUTER Eh

OUTER END SEAL (FELT AND RUBBER))

OUTER END SEAL (SPRIN< LOADED)]

'SPRING LOADED SEAL RETAINER}

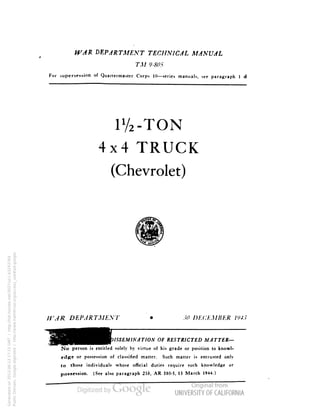

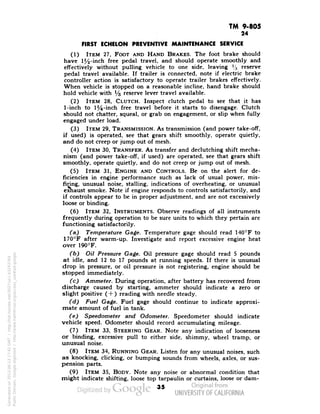

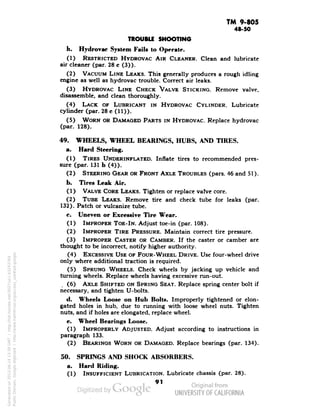

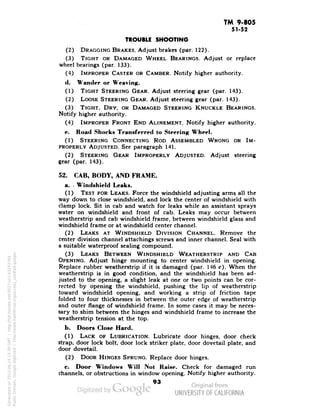

OUTER END SEAL INNER RETAINER ^^^^ RA PD 33046

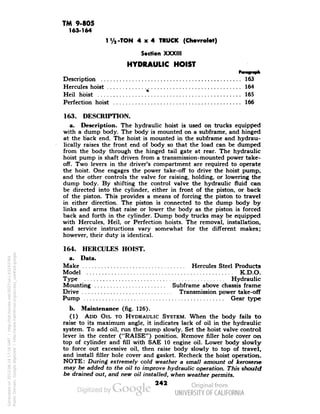

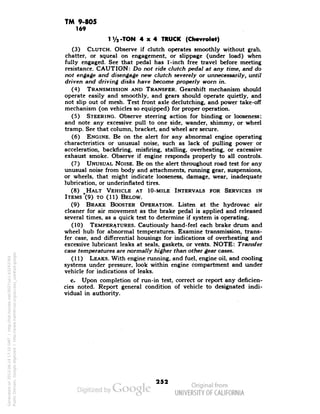

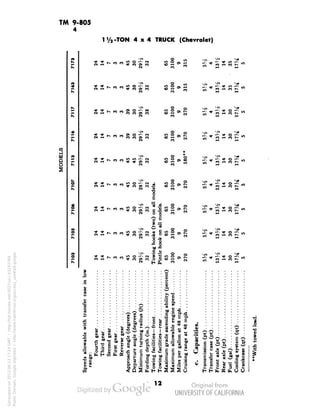

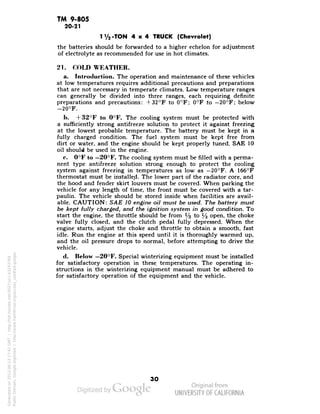

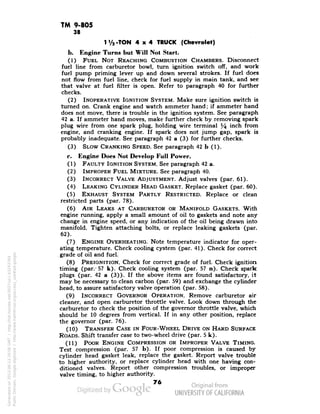

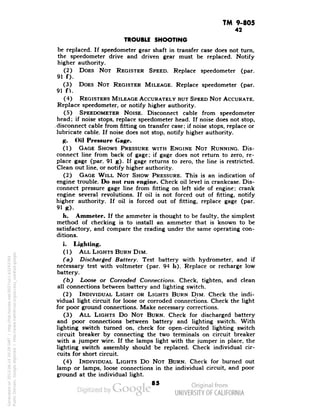

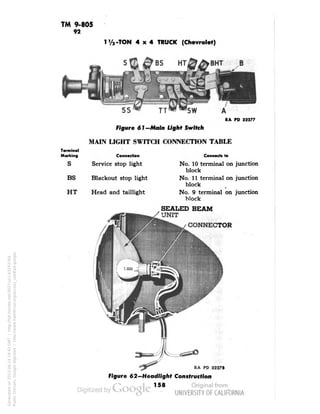

Figure 83—Outer Seal Replacement

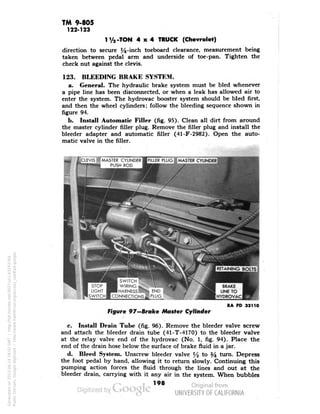

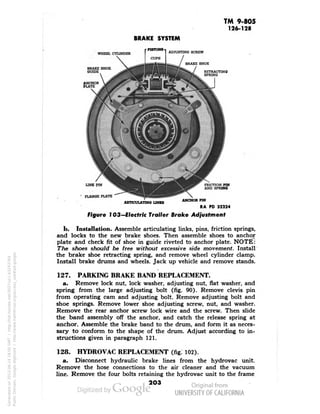

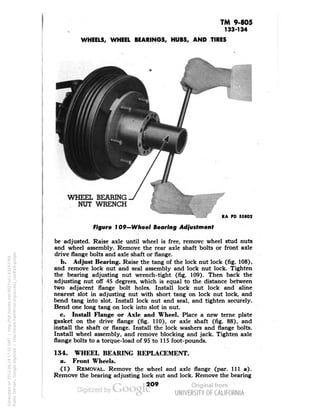

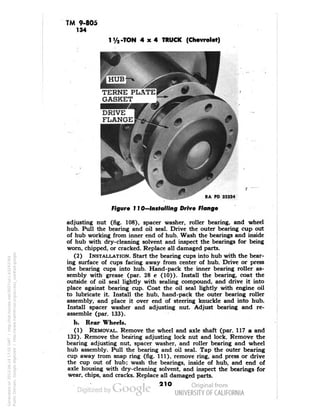

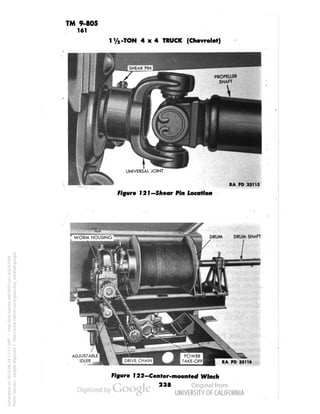

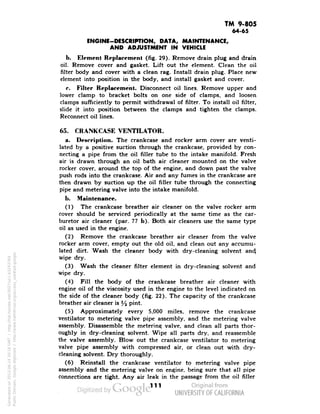

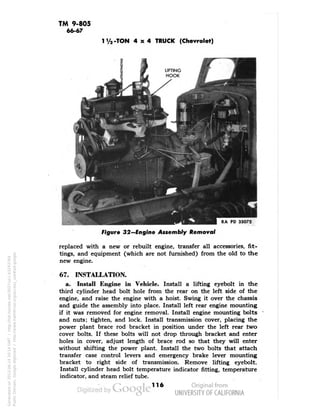

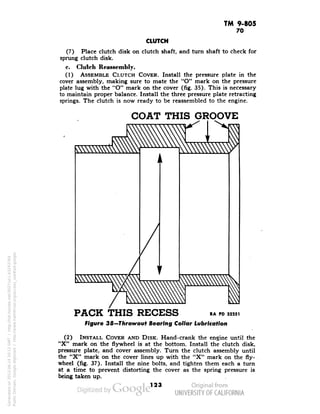

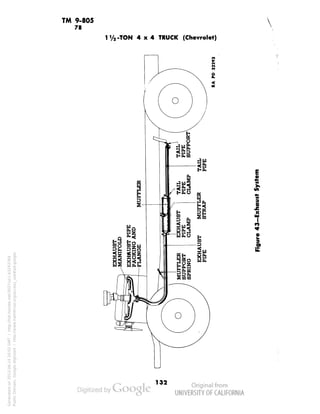

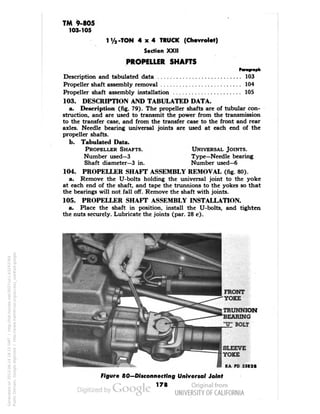

b. Installation. Place a new seal retainer gasket on knuckle sup-port

with the diagonal cut as close to top as possible, and make sure

bolt holes line up. Install the seal retainer. Place the new outer end

seal (felt and rubber) in the retainer so that the taper of seal fits

the curvature of the axle outer end ball, and the diagonal cut will

be at the top. Place the spring-loaded seal and seal retainer against

the felt and rubber seal, and install the lower half of the inner

retainer, holding it in place with two or three cap screws installed

loosely. Position the spring-loaded seal uniformly around the

spherical bolt with a small screwdriver, and install the upper half

of the inner retainer. Install and tighten all of the retainer cap

screws.

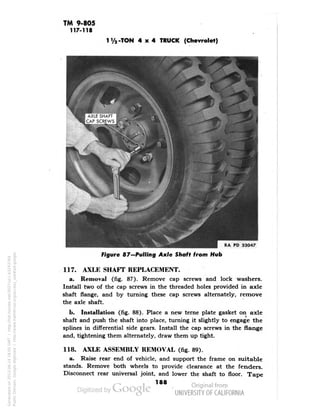

111. AXLE SHAFT REPLACEMENT (EITHER SHAFT).

a. Removal (fig. 84).

(1) REMOVE WHEELS. Loosen the six wheel stud nuts on front

wheel two turns. Raise front of vehicle until the wheel clears the

ground, and support axle housing on jack stand or suitable blocks.

Remove the six wheel stud nuts that were previously loosened, and

remove the wheel.

(2) REMOVE HUB. Remove the eight bolts and lock washers

attaching drive flange to hub. Install two bolts in the tapped holes

of flange; screw them in alternately to remove flange. Raise the tangs

182

Generated on 2013-06-14 18:13 GMT / http://hdl.handle.net/2027/uc1.b3243764

Public Domain, Google-digitized / http://www.hathitrust.org/access_use#pd-google](https://image.slidesharecdn.com/tm9-805-141108052035-conversion-gate02/85/TM-9-805-181-320.jpg)