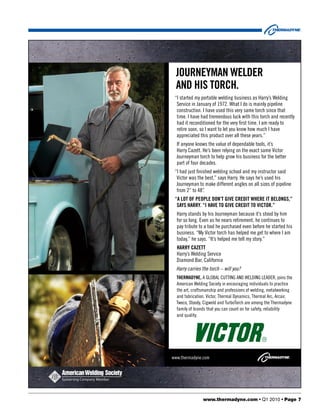

This document is a newsletter from Thermadyne updating distributors on new products, promotions, and company initiatives for the first quarter of 2010. It highlights the new Victor Professional Edge Series regulators which include built-in gauges and user-friendly design. It also discusses Thermadyne's focus on exceeding customer expectations through initiatives to improve culture, communications, and benchmarking against other companies. The president notes feedback that Thermadyne's service is improving and expects the company to continue leading in customer service through 2010.

![Sky Spindt, Torchmate expert on the scene at Praxair exhibit space

TORCHMATE CNC CUTTING SYSTEMS, a leading

manufacturer of affordable CNC cutting systems,

has relied on Thermadyne Automation to meet its

goal in bringing automation to metal fabricating

Brad Williams and Koike Product Expert, Tim Joslin

shops, providing the highest quality service.

“Thermadyne Automation is a total partner with KOIKE ARONSON, INC., a manufacturer of high

us,” stated Bill Kunz, Torchmate CNC Cutting quality welding and cutting equipment, recently

Systems CEO. “They make it possible for us looked to Thermadyne Automation for continued

to deliver on our promise of the best customer customer growth. Always seeking to offer new

service. They have made us a priority and take it products, Koike decided to investigate the new

personally when a problem occurs on any level. Auto-Cut and Ultra-Cut plasma systems from

Responding immediately, they step in and handle Thermal Dynamics. After several months of testing

the situation right away.” and training the company was ready to take

the Thermal Dynamics products to market and

enhance its customer base.

“Thermal Dynamics, backed by Thermadyne’s

technical and product support, has been

outstanding,” replied Brad Williams, Koike National

Sales Manager. “Prompt delivery has allowed us to

operate under just-in-time conditions. This is a big

plus when storage space is limited due to a large

Carlo Borella and Russ Gallup of FastCut

backlog of orders.”

FASTCUT CNC sells CNC plasma cutting systems. “Playing a pivotal role to our company, each

When the company was in need of additional of these outstanding partners has helped pave

power supply resources, Thermadyne Automation the way to Thermadyne’s success,” stated

provided a solution. FastCut now sells Thermal Richard Morgan, Director of Automation Sales.

Dynamics Cutmaster A-Series, Auto-Cut and Ultra- “We value our partnerships and look forward to

Cut plasma systems with FastCut cutting tables. helping other companies improve their operations

“Whether it’s superior cut on gauge material or through automation.”

heavier metal plate end users seek, Thermadyne

Automation has the answer,” said FastCut Partner

Carlo Borella. “They [Thermadyne] work with

us. They are open to new ideas. They’re always

listening to what we need – no other supplier

comes close.”

www.thermadyne.com • Q1 2010 • Page 13](https://image.slidesharecdn.com/thmdnewsltr2010-111229191026-phpapp02/85/THMD-newsltr-2010-13-320.jpg)