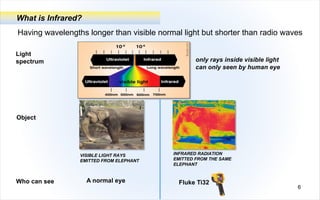

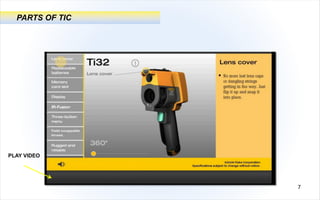

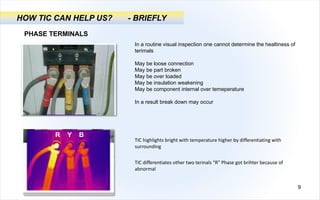

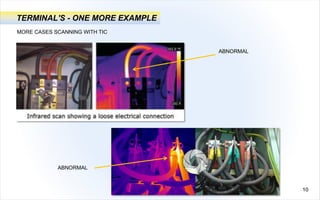

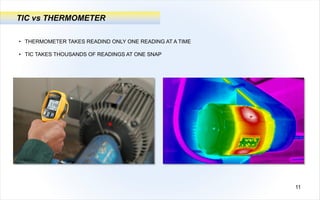

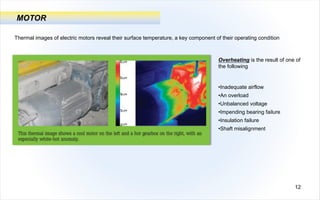

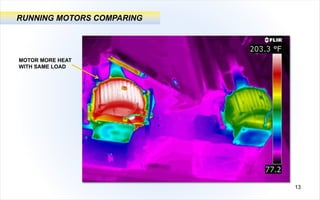

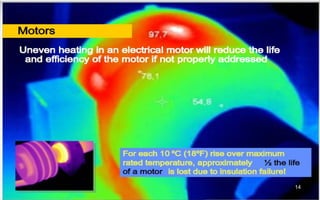

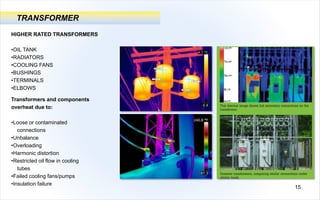

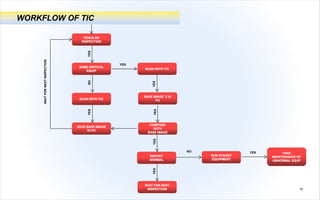

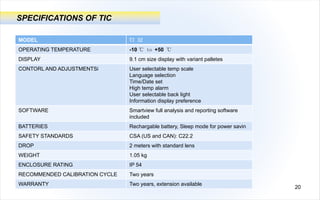

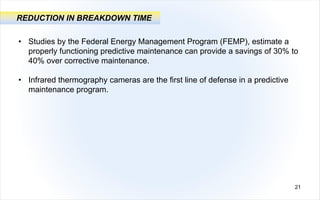

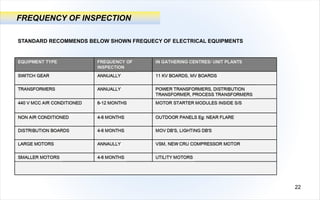

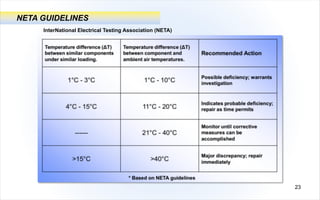

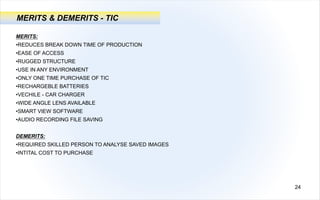

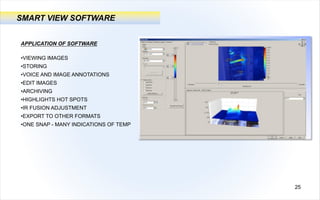

The document presents an overview of thermal infrared cameras (TIC) used for electrical condition monitoring in industries like oil and gas. It discusses the technology behind TIC, its applications in detecting potential electrical equipment failures, and its advantages over traditional thermometers. Additionally, it outlines specifications, maintenance guidelines, and software applications related to TIC.