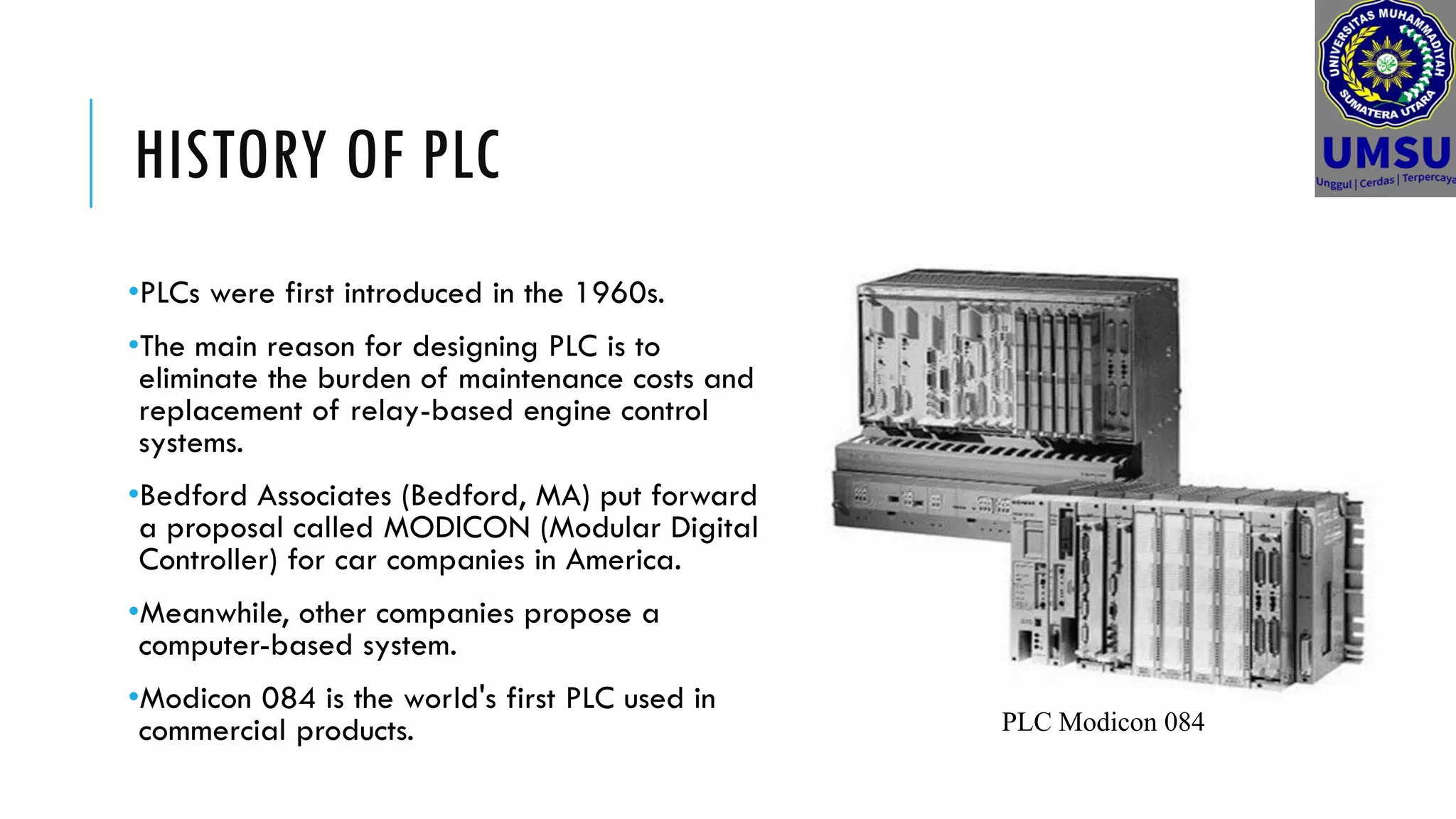

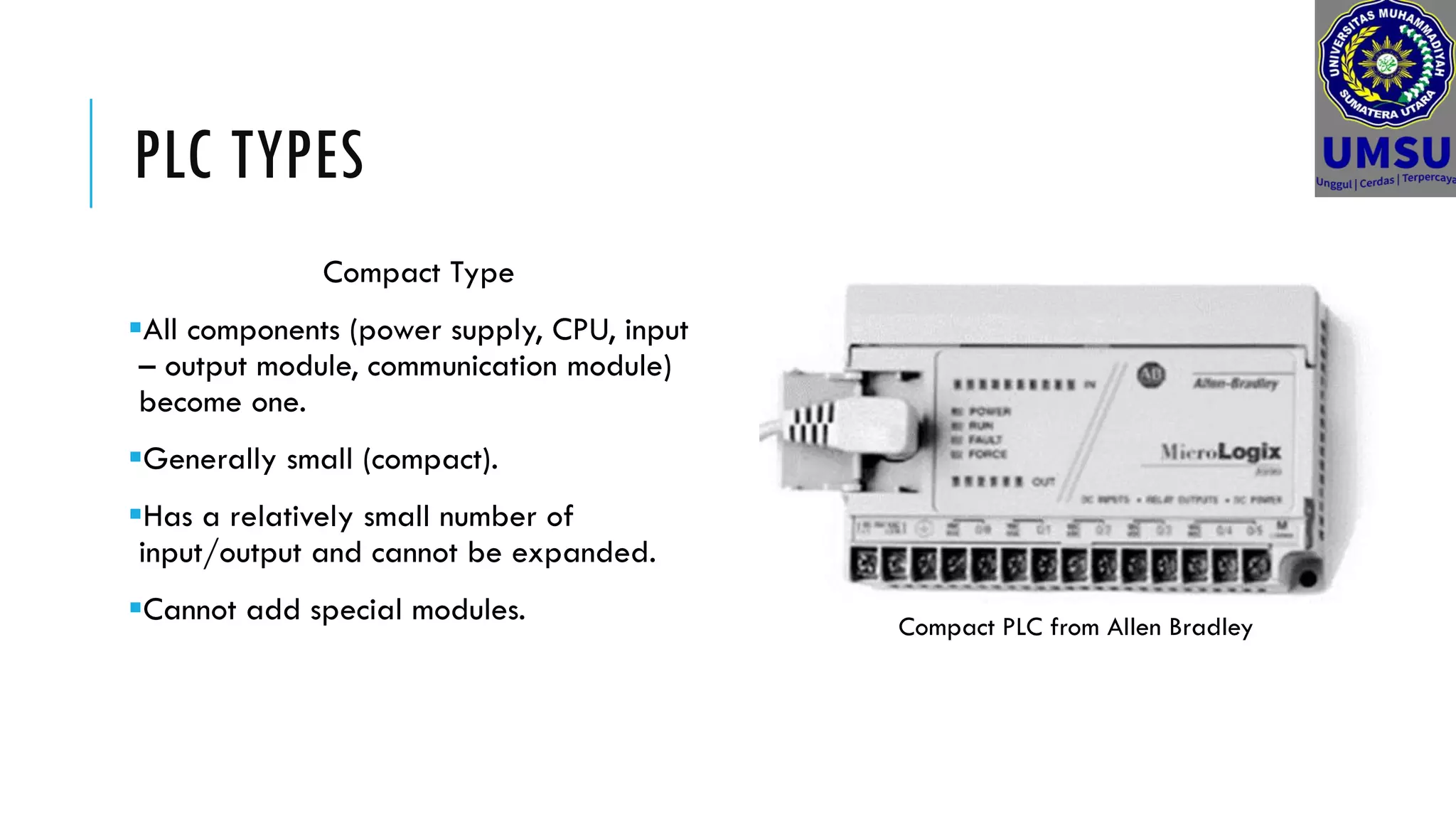

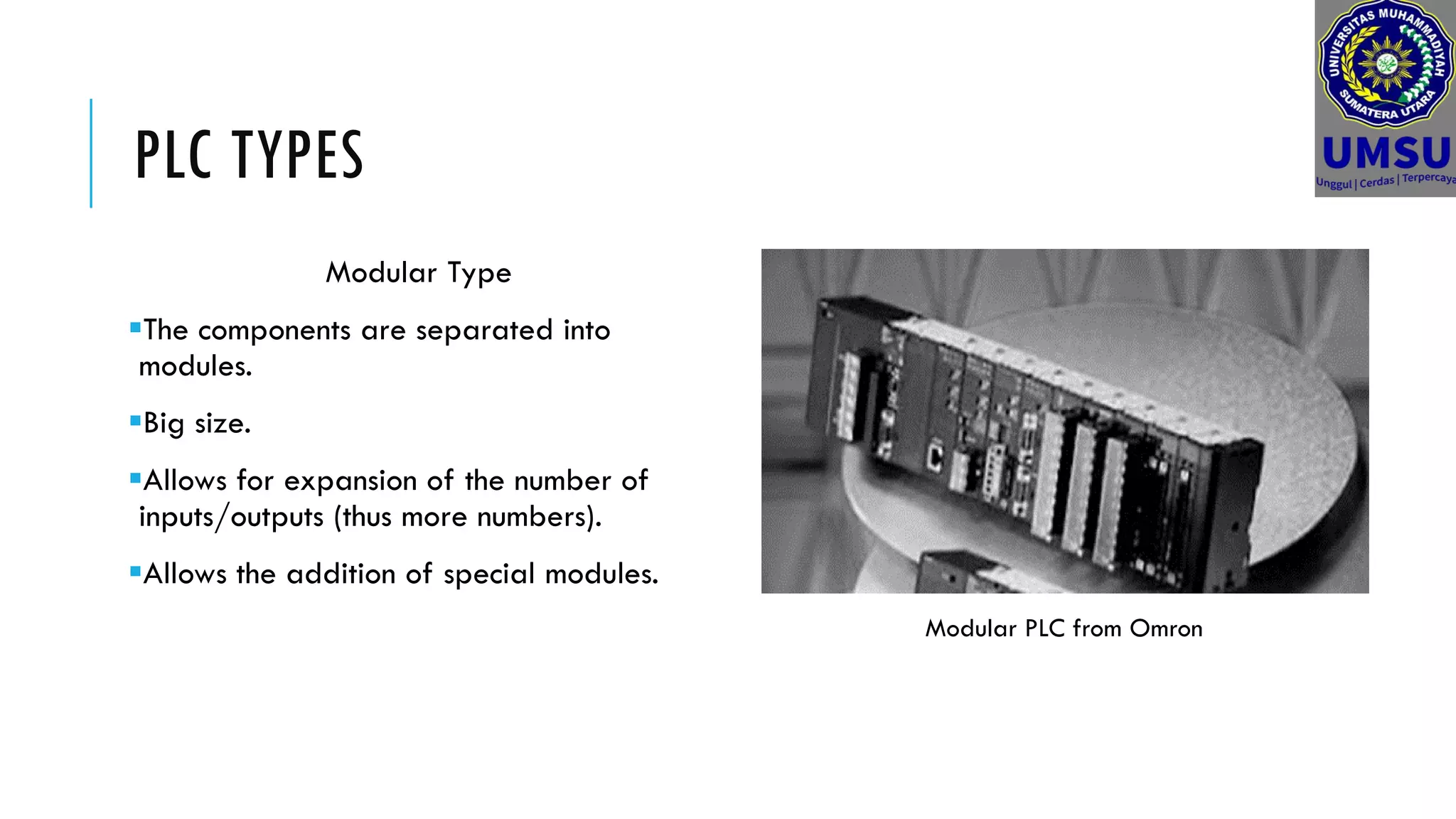

PLCs were first introduced in the 1960s to eliminate the high maintenance costs of relay-based control systems. The first commercial PLC was the Modicon 084. Through the 1970s-1980s, PLC technology advanced with new processors and communication capabilities. Standards like IEC 1131-3 were developed to unify programming languages. Today, PLCs are smaller and more powerful, with faster processing, expanded I/O, improved programming software, and strong communication abilities. PLCs also come in compact or modular designs to suit different application needs.