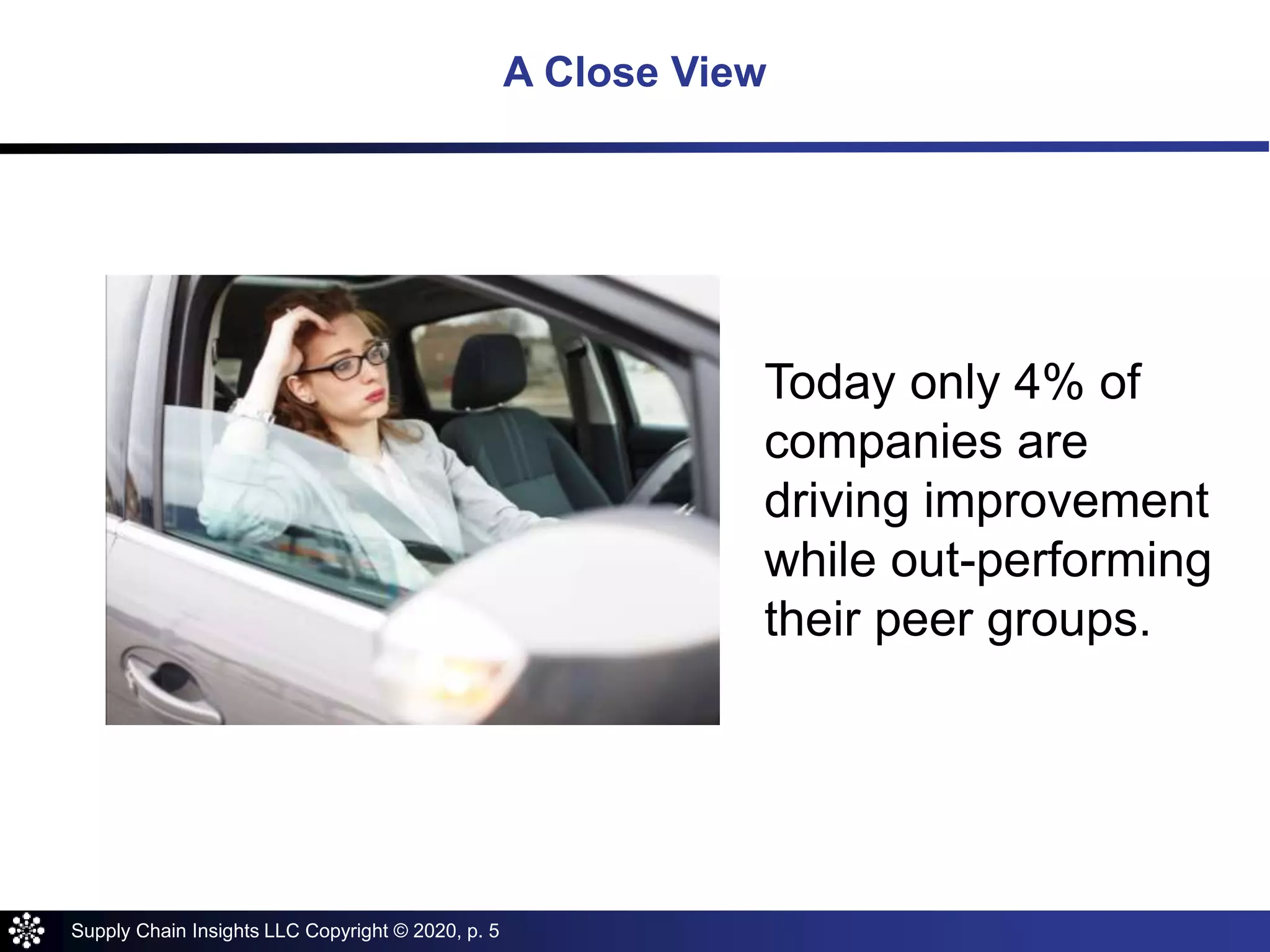

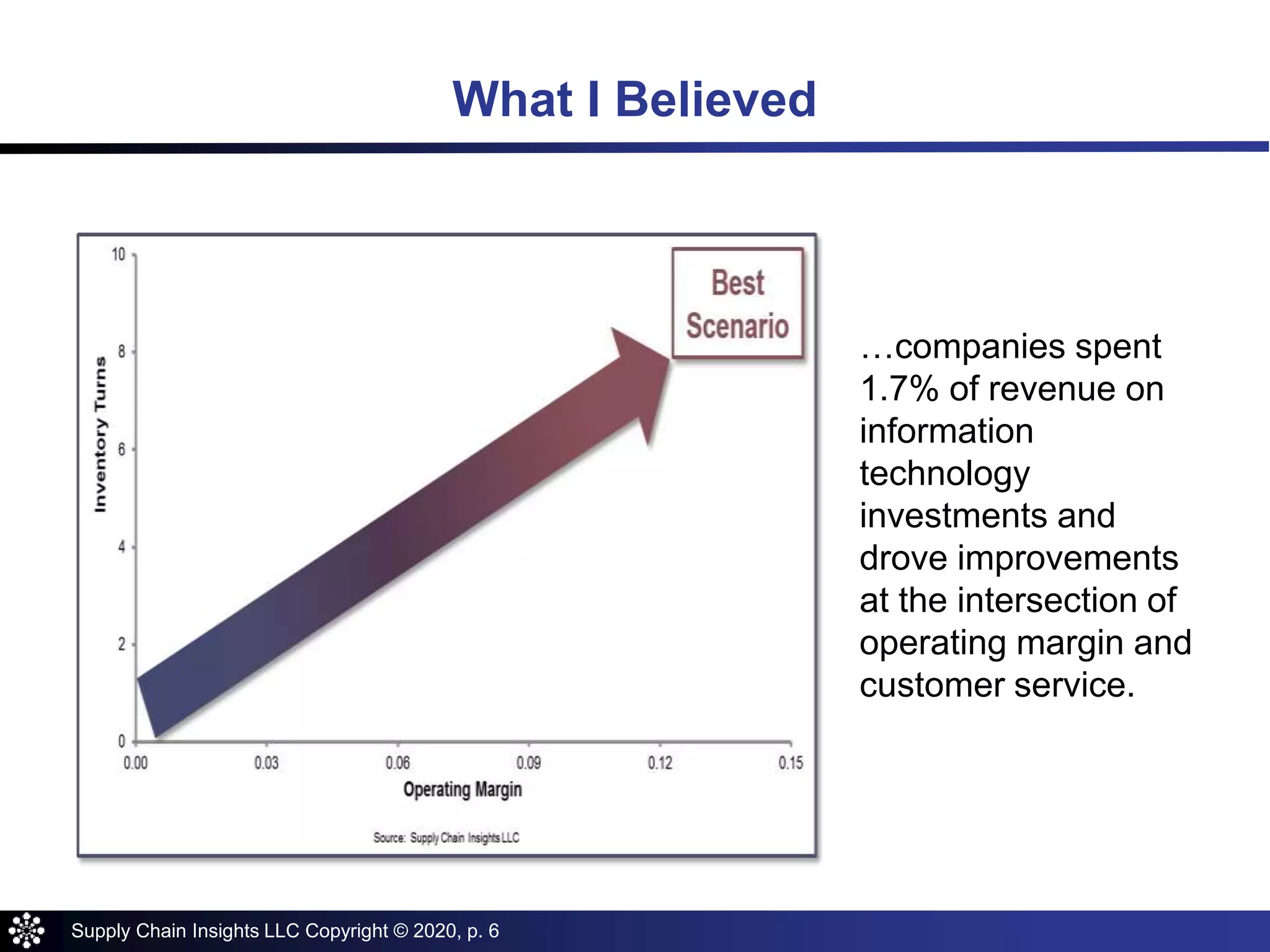

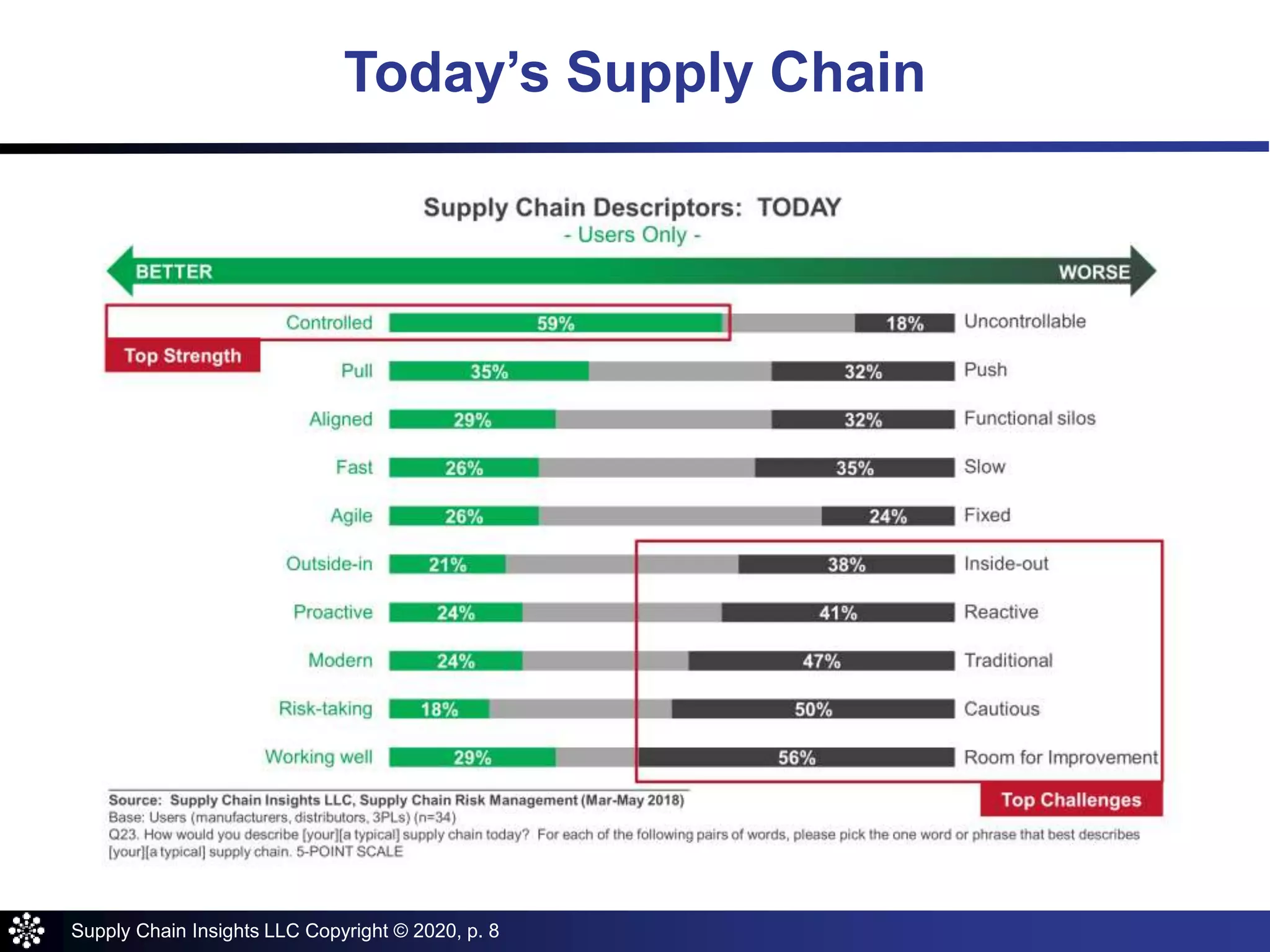

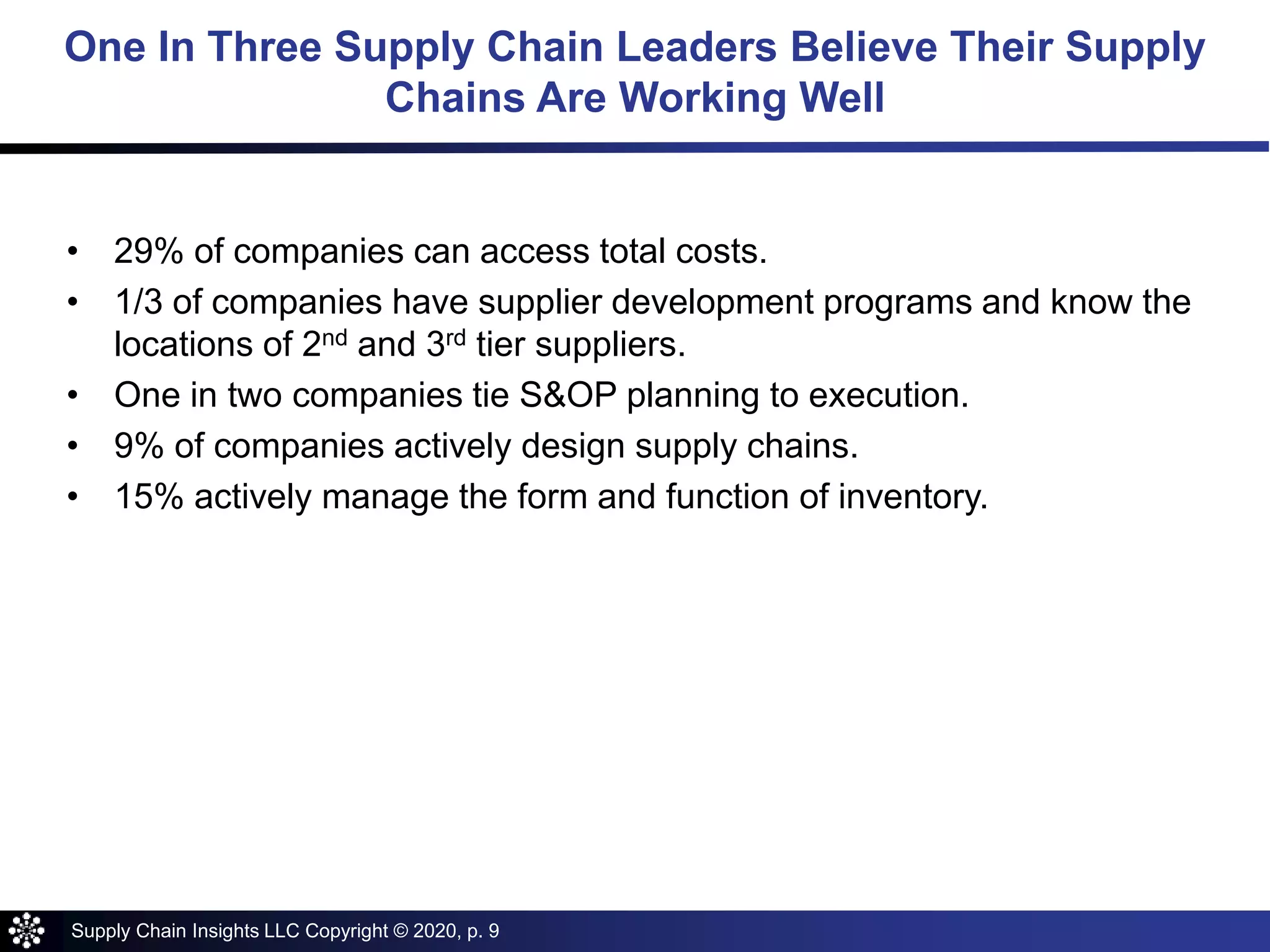

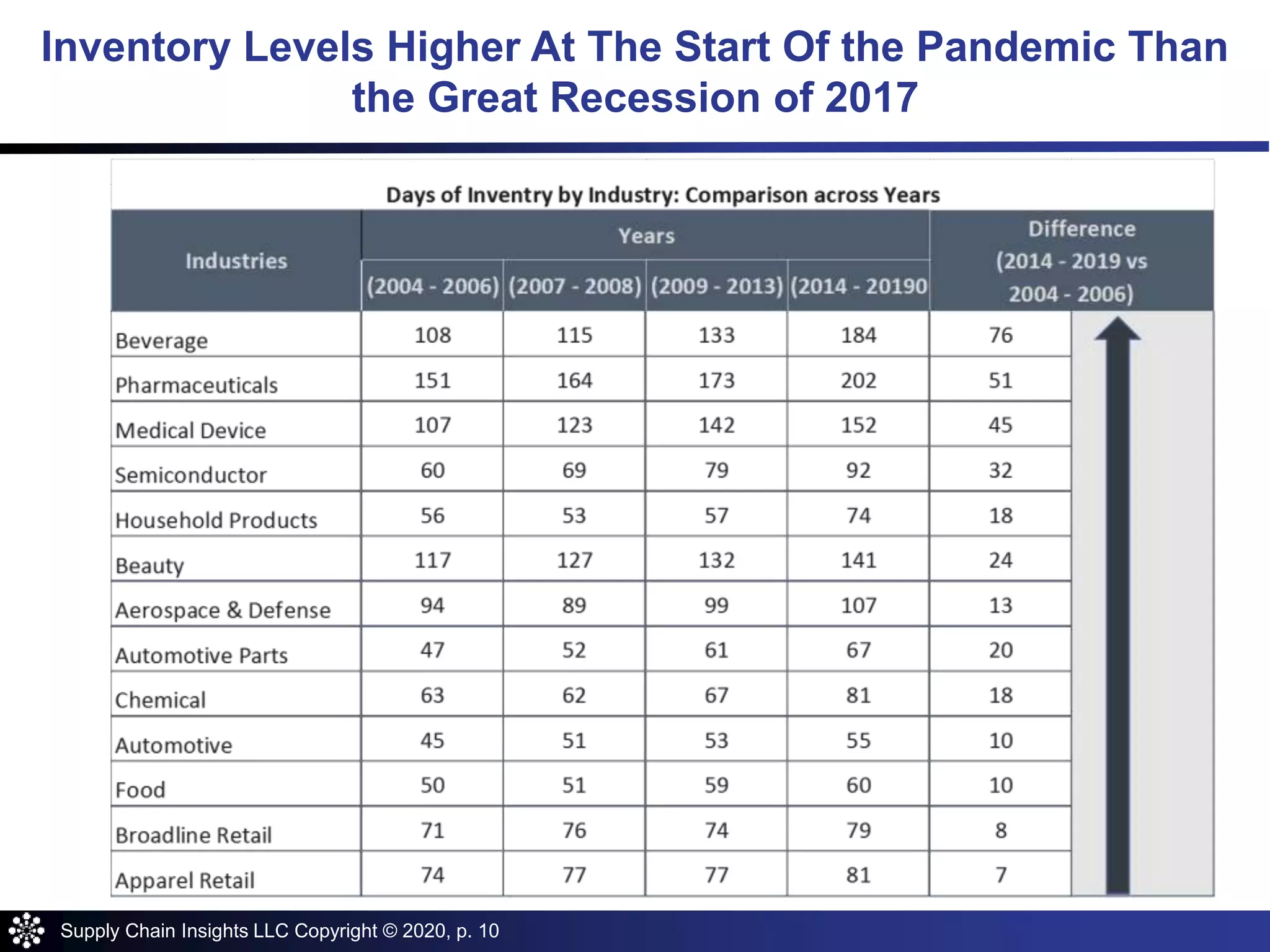

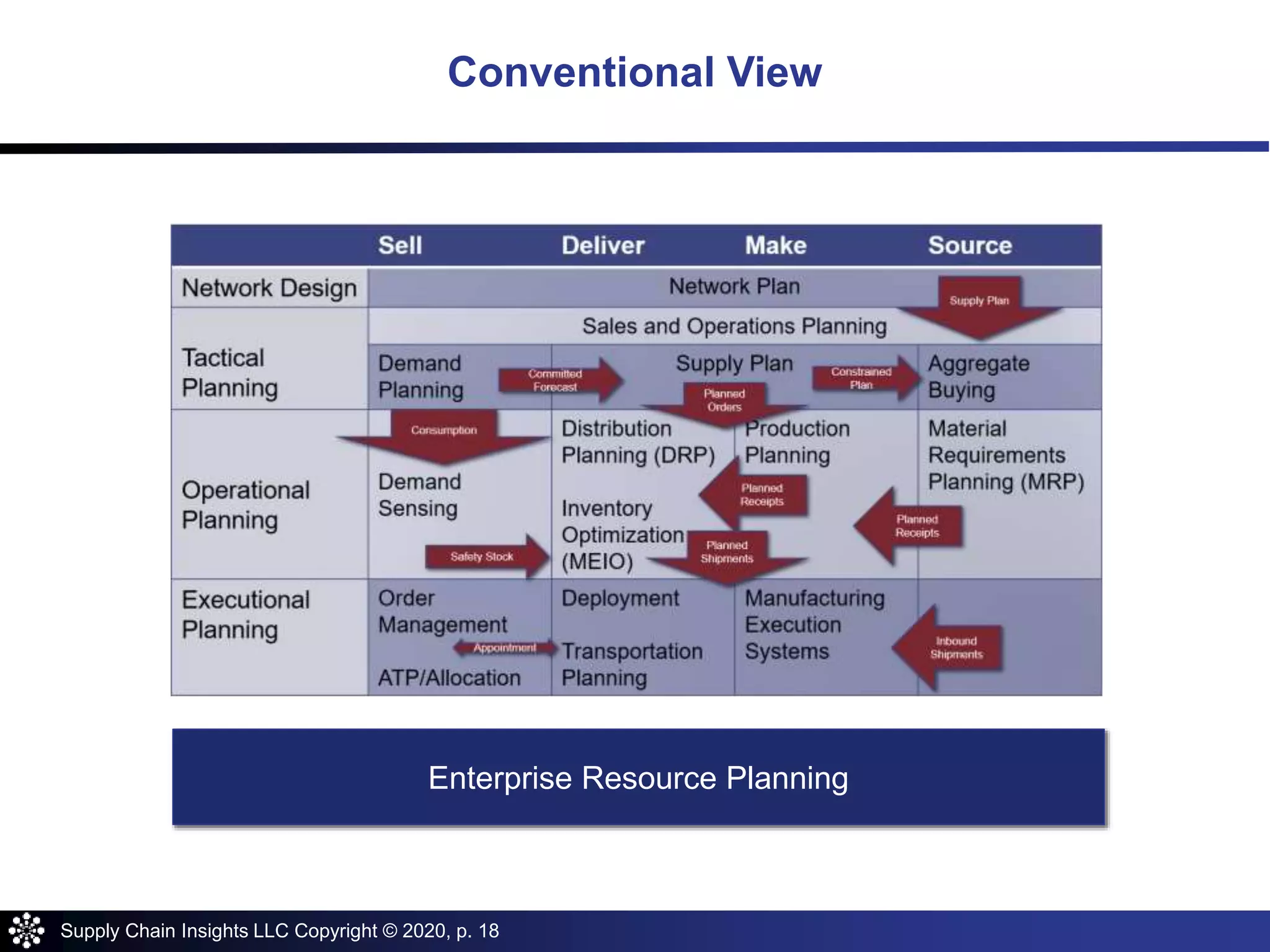

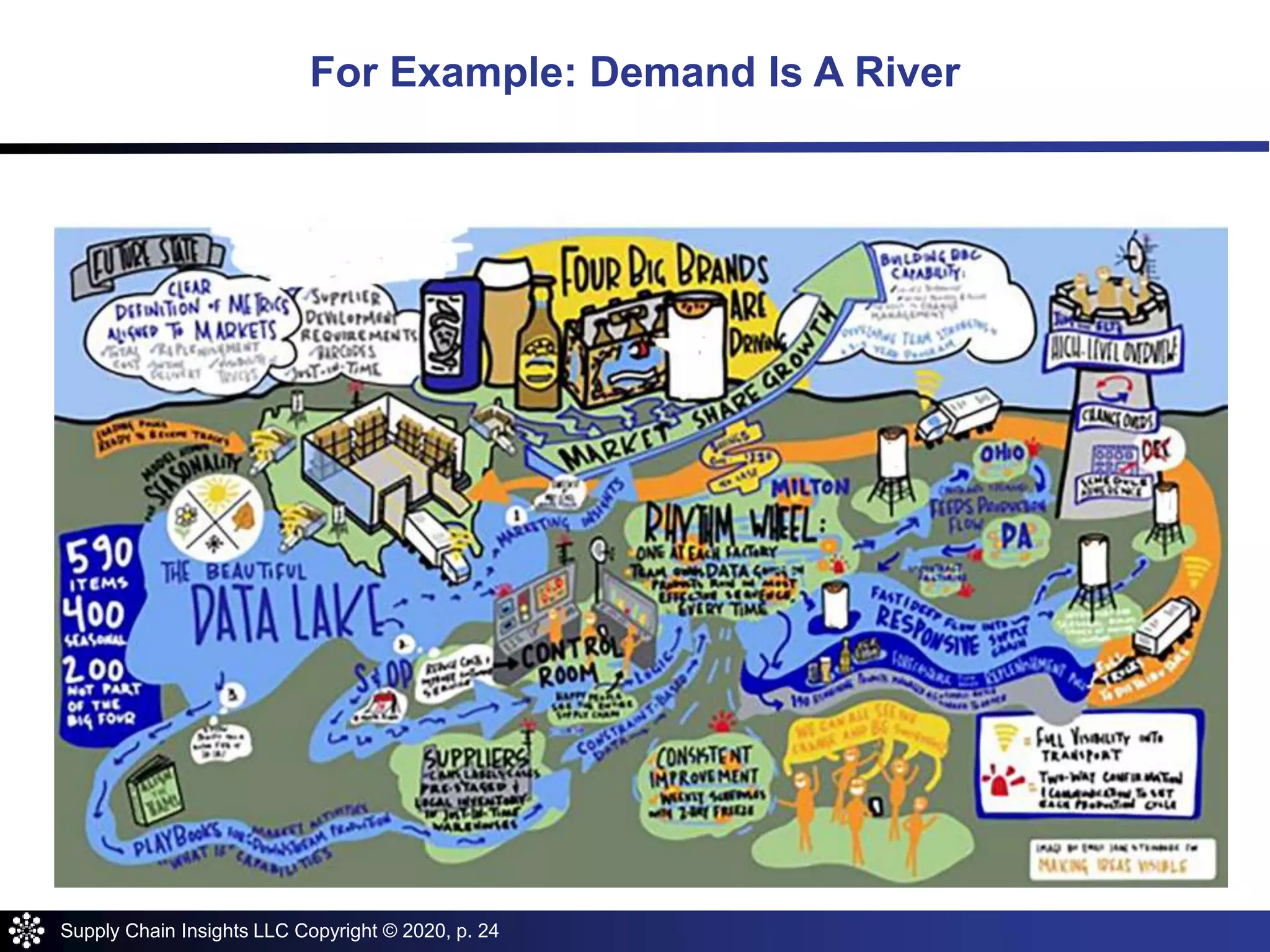

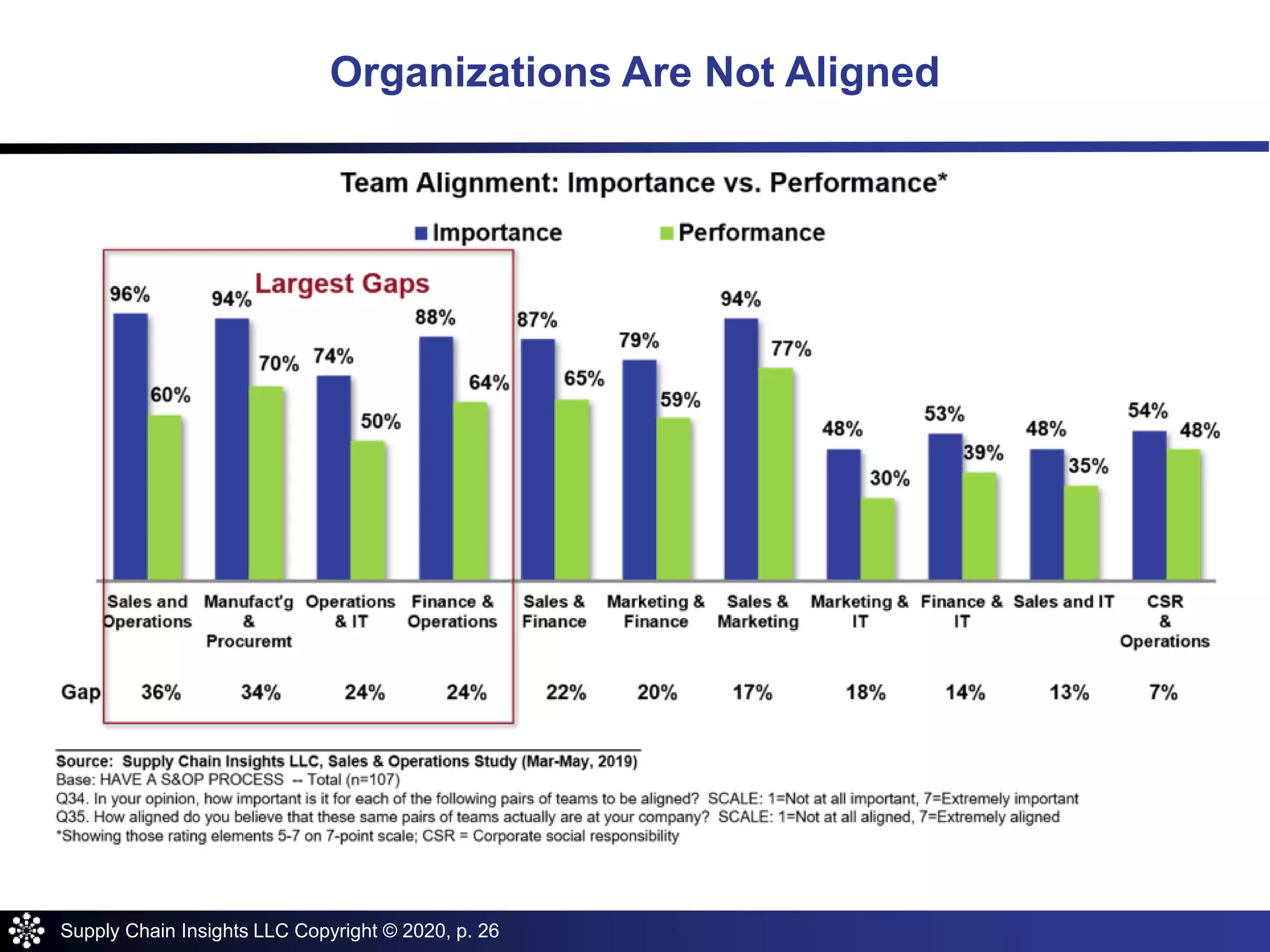

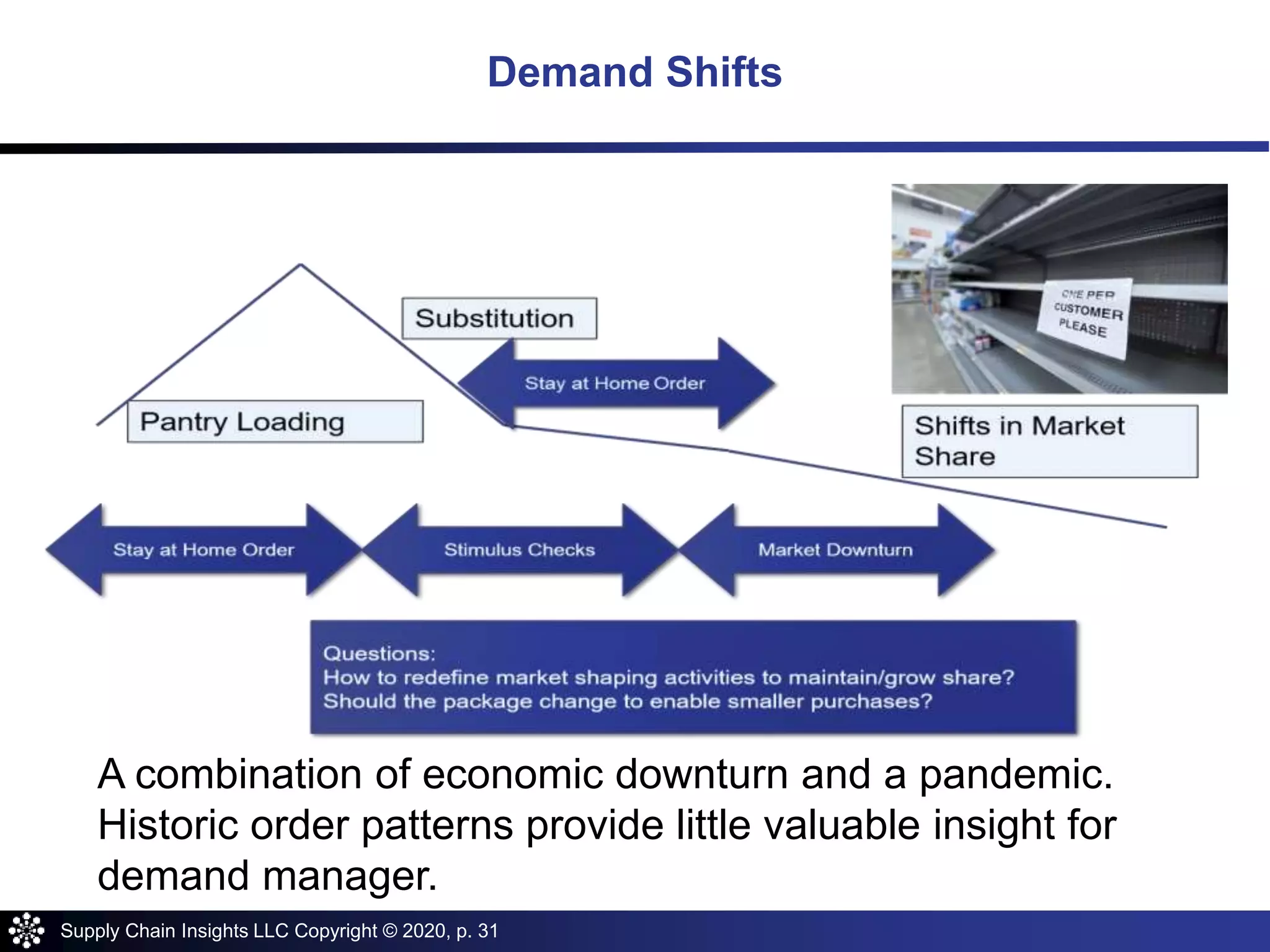

The document discusses the shortcomings of current supply chain integration efforts and emphasizes the need for synchronization and interoperability rather than traditional integration. It highlights the impact of the COVID-19 pandemic on supply chains, the importance of aligning demand and supply, and adopting new analytics and planning approaches. The author suggests forming operational and recovery teams to adapt to changing market conditions and improve overall supply chain effectiveness.