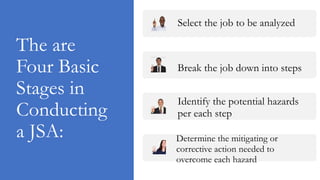

This document summarizes a February 2022 safety presentation on job safety/hazard analysis (JSA). It defines a JSA as a method to identify hazards by breaking down work processes. Conducting a JSA has benefits like reducing injuries and increasing productivity. The presentation outlines the four basic stages to conducting a JSA: selecting a job, breaking it into steps, identifying hazards per step, and determining corrective actions. It also discusses factors to consider when selecting jobs for analysis and questions to ask when evaluating hazards. Finally, it introduces the hierarchy of controls for mitigating identified hazards from elimination to personal protective equipment.