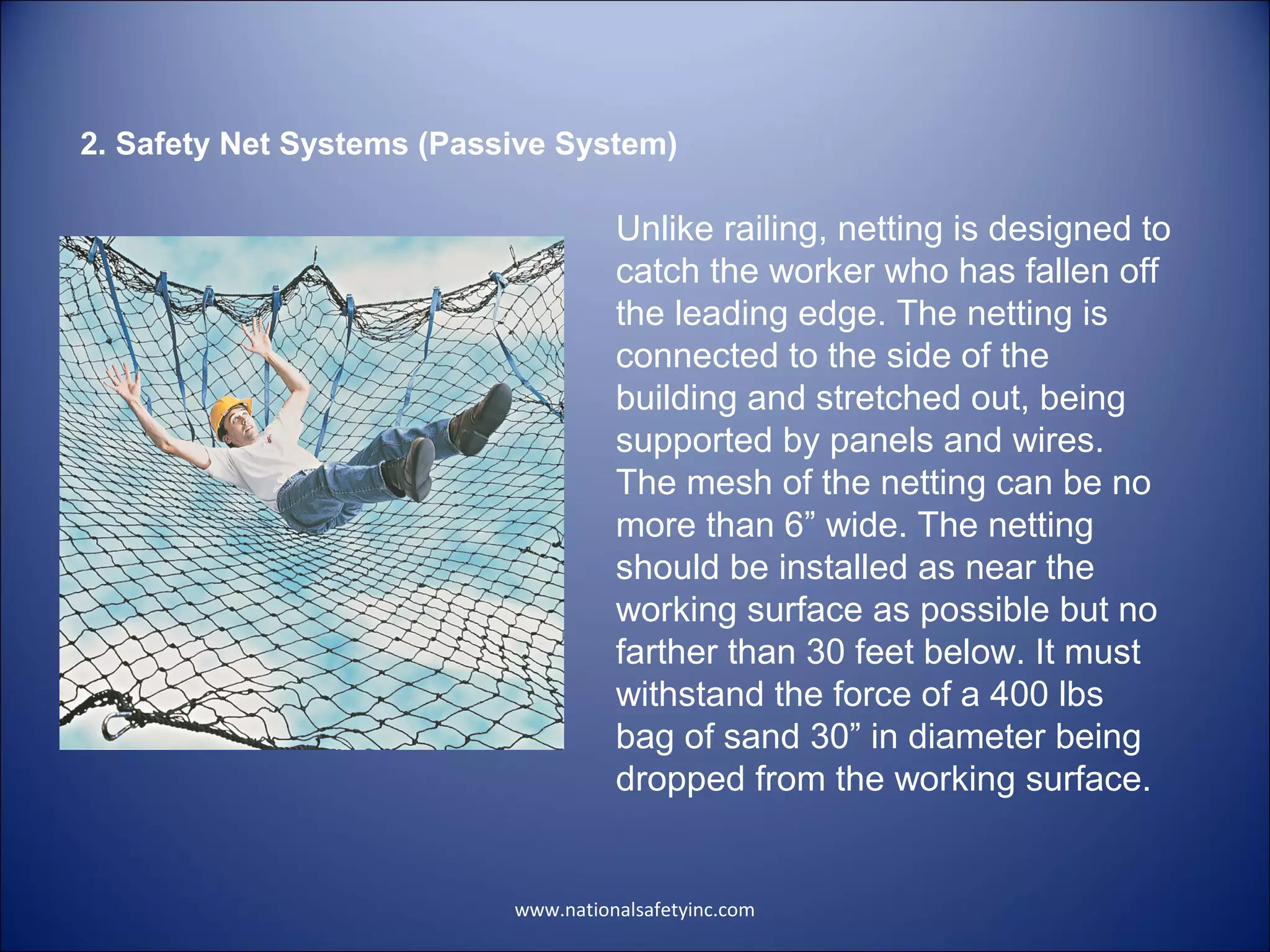

The document discusses the basics of fall protection. It explains that fall protection requires following basic principles and rules to be effective rather than being overwhelming. It then summarizes the key OSHA regulations requiring fall protection when working 6 feet or more above a lower level. It provides details on the three main types of fall protection systems - guardrail systems, safety net systems, and personal fall arrest systems - and their components and requirements.