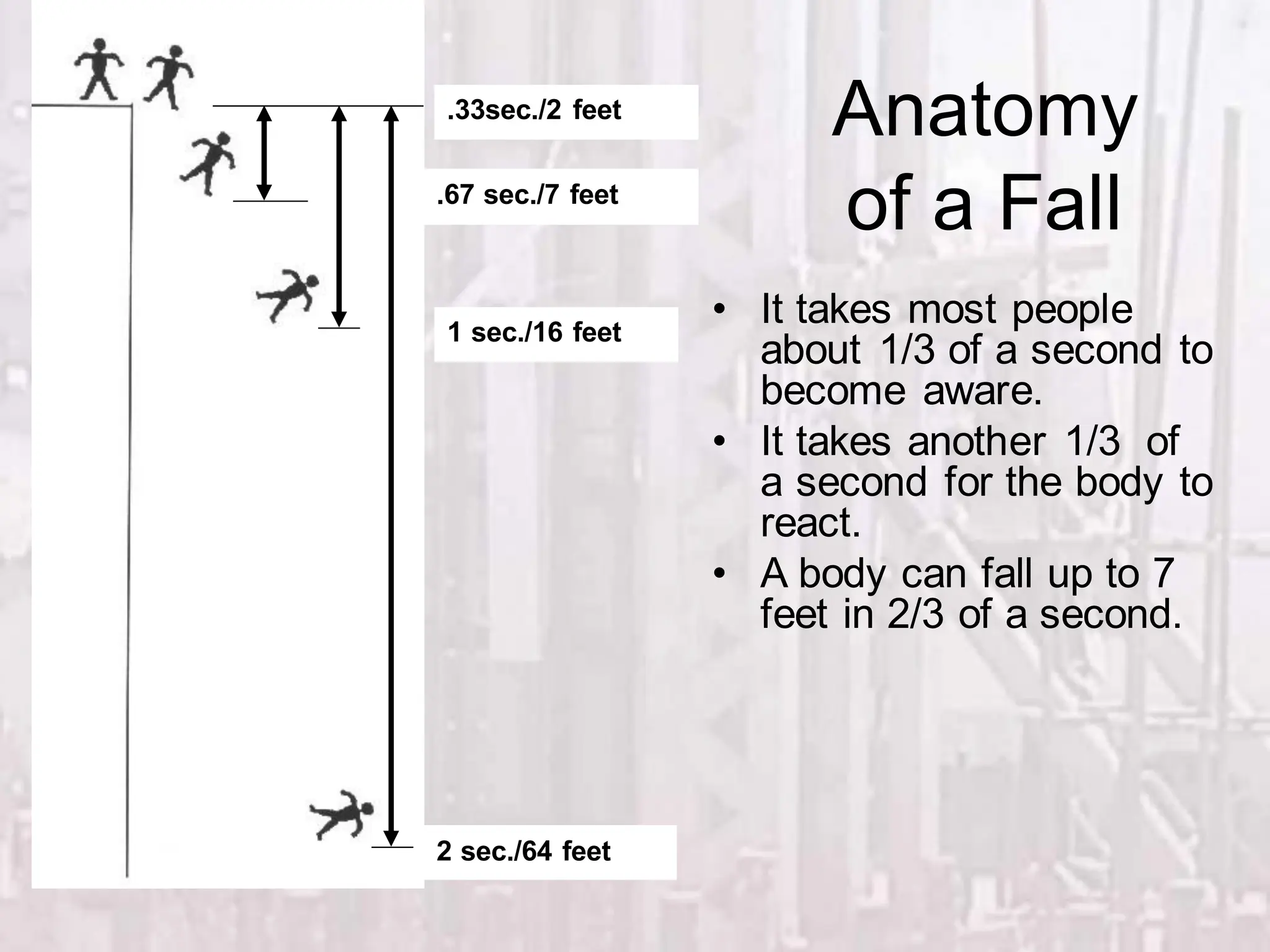

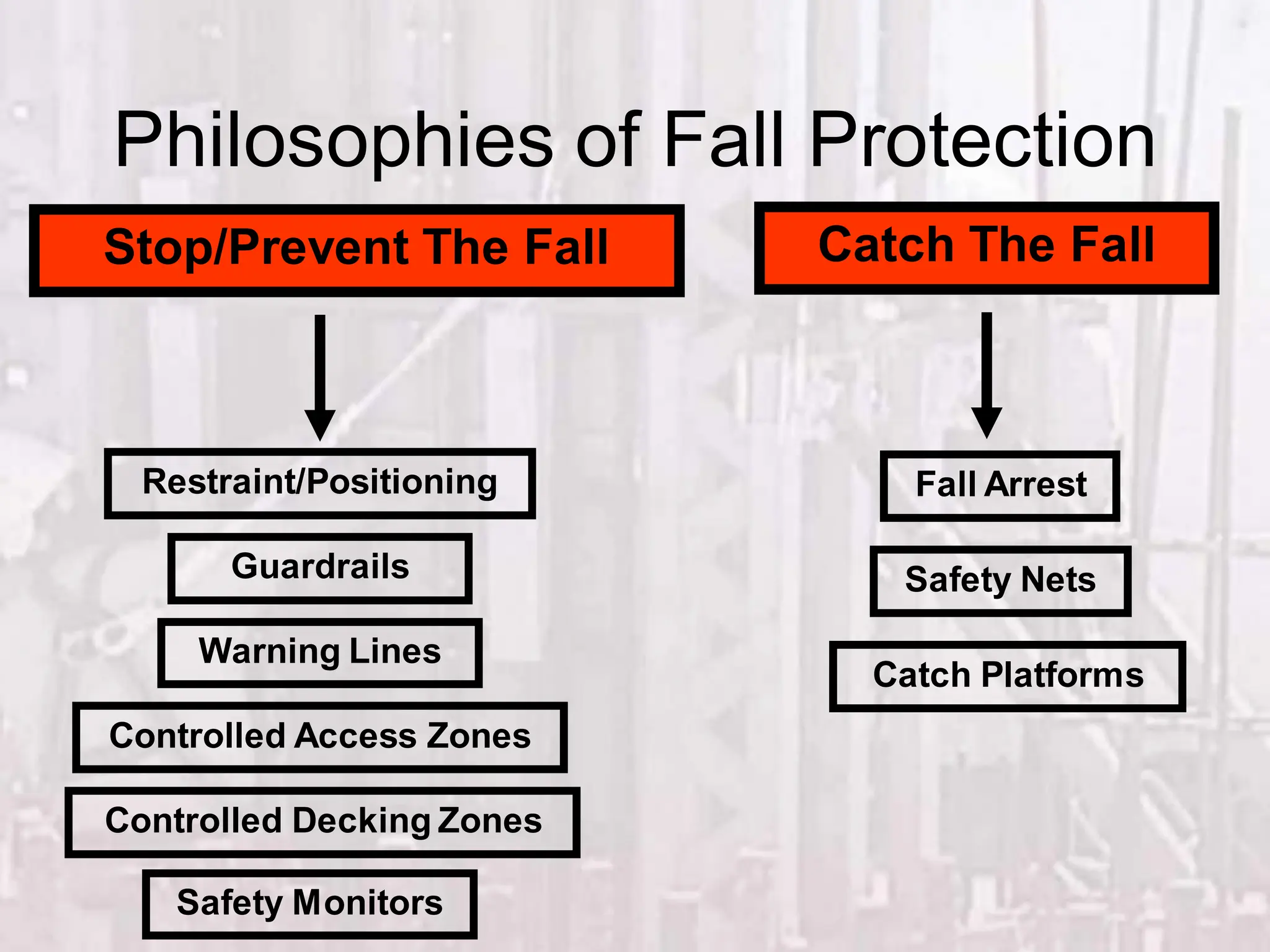

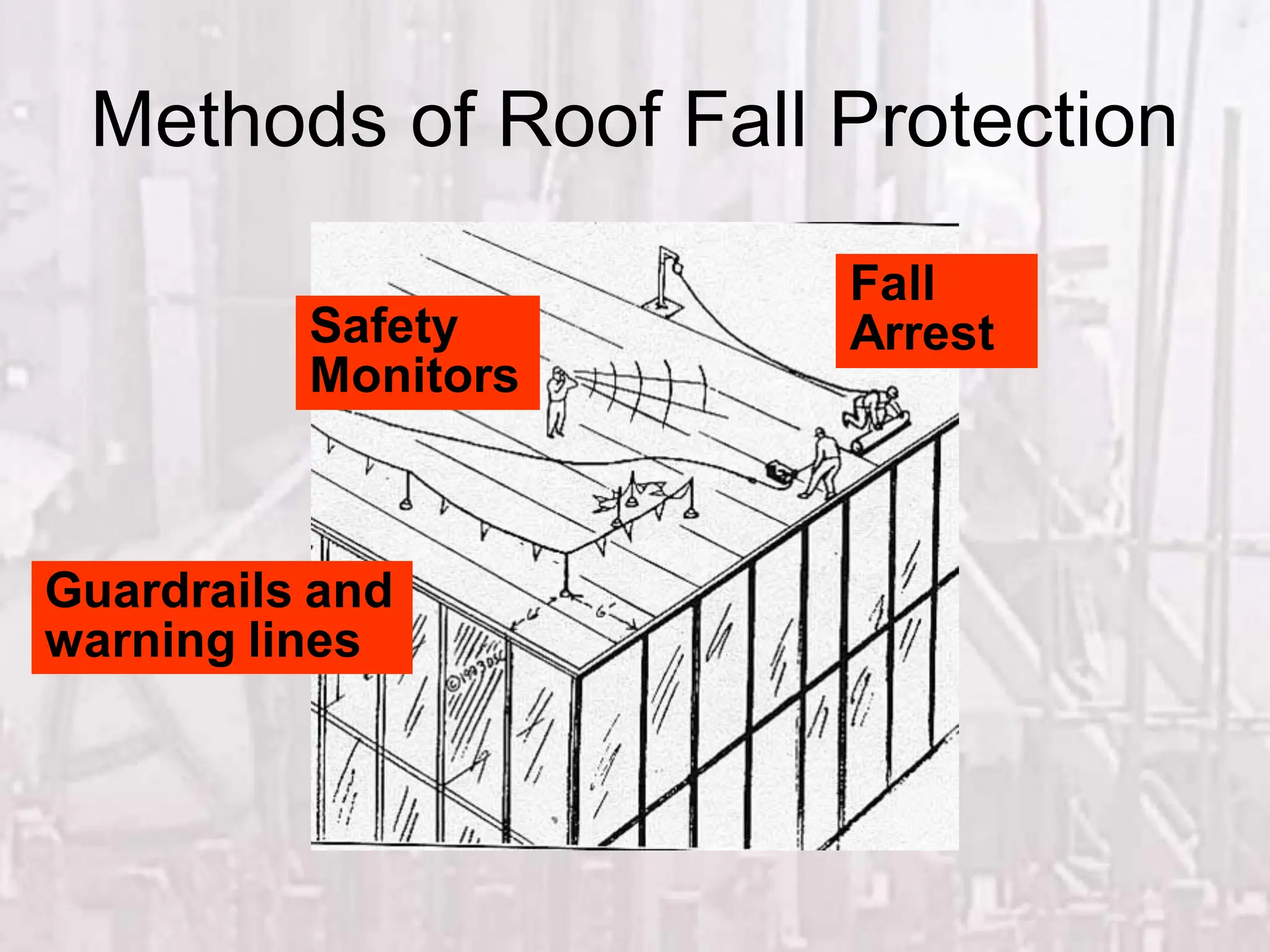

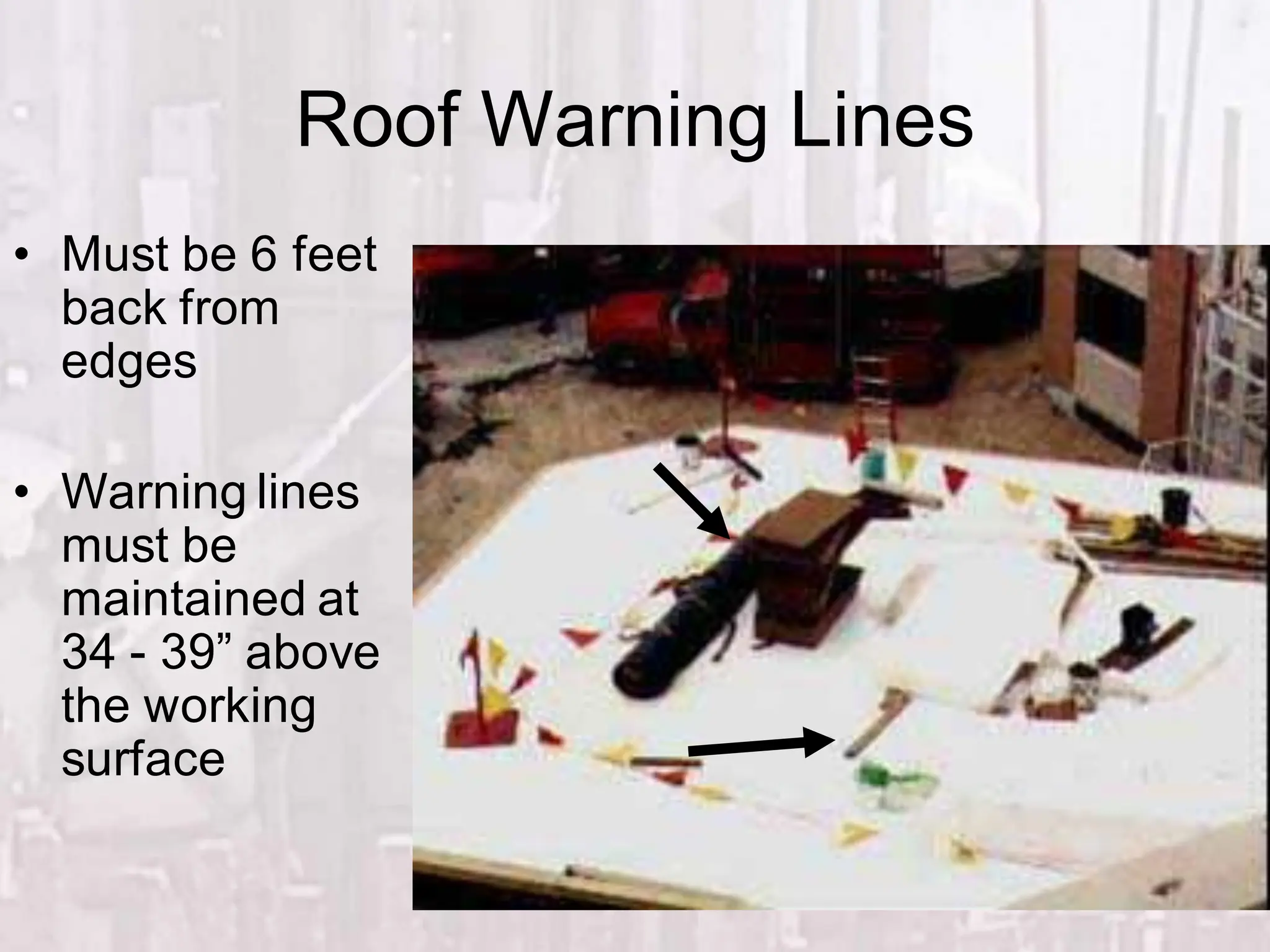

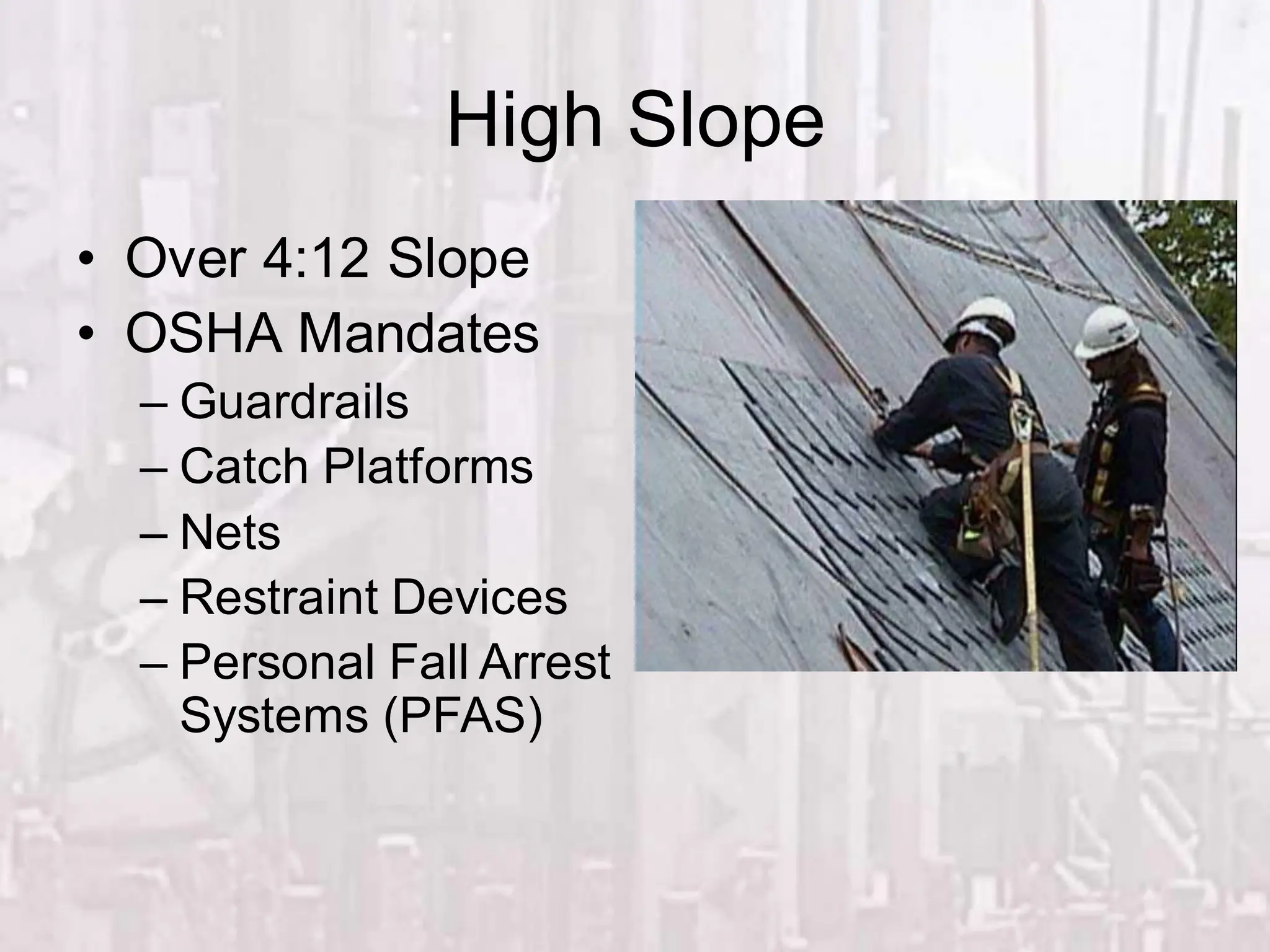

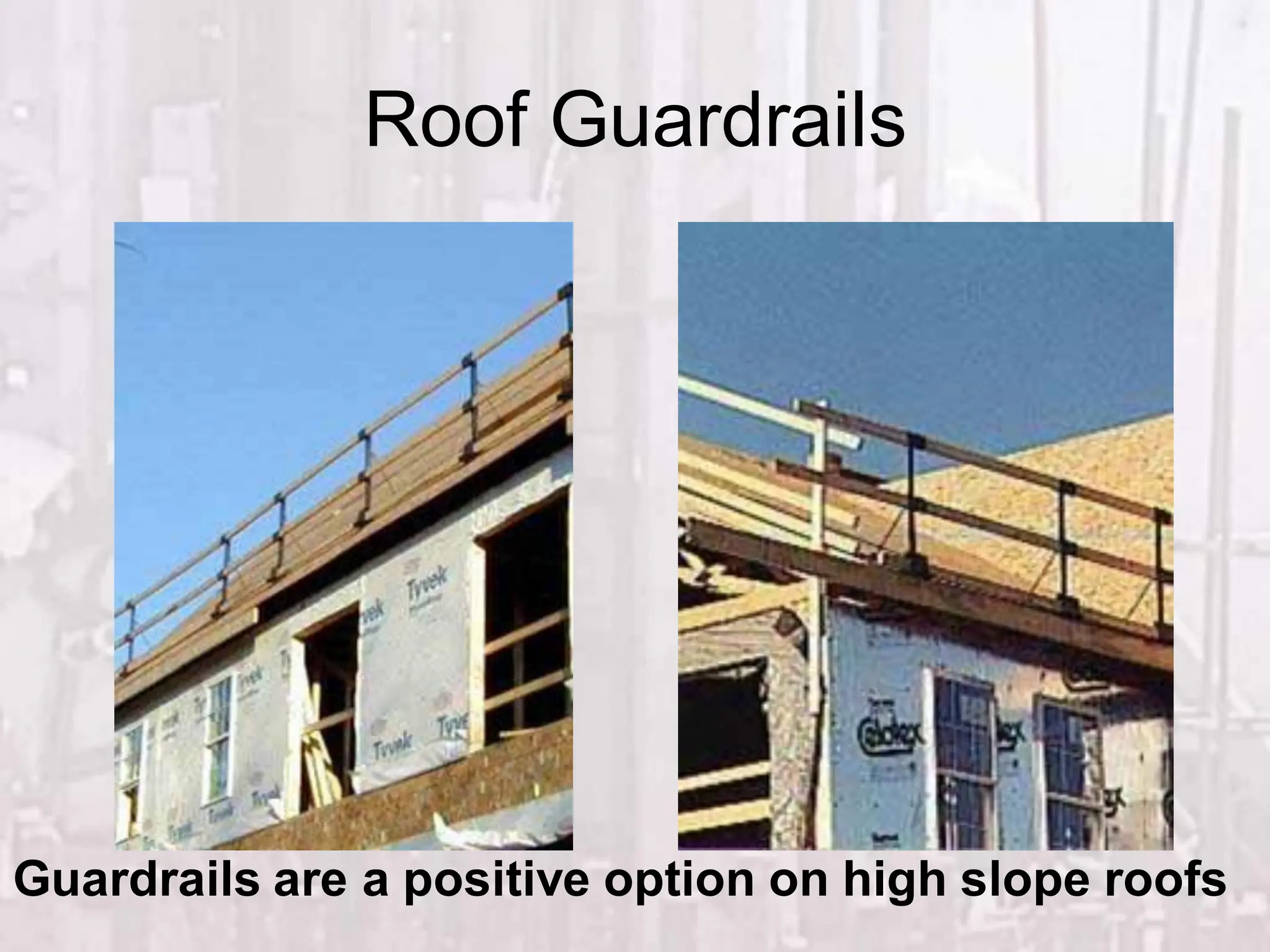

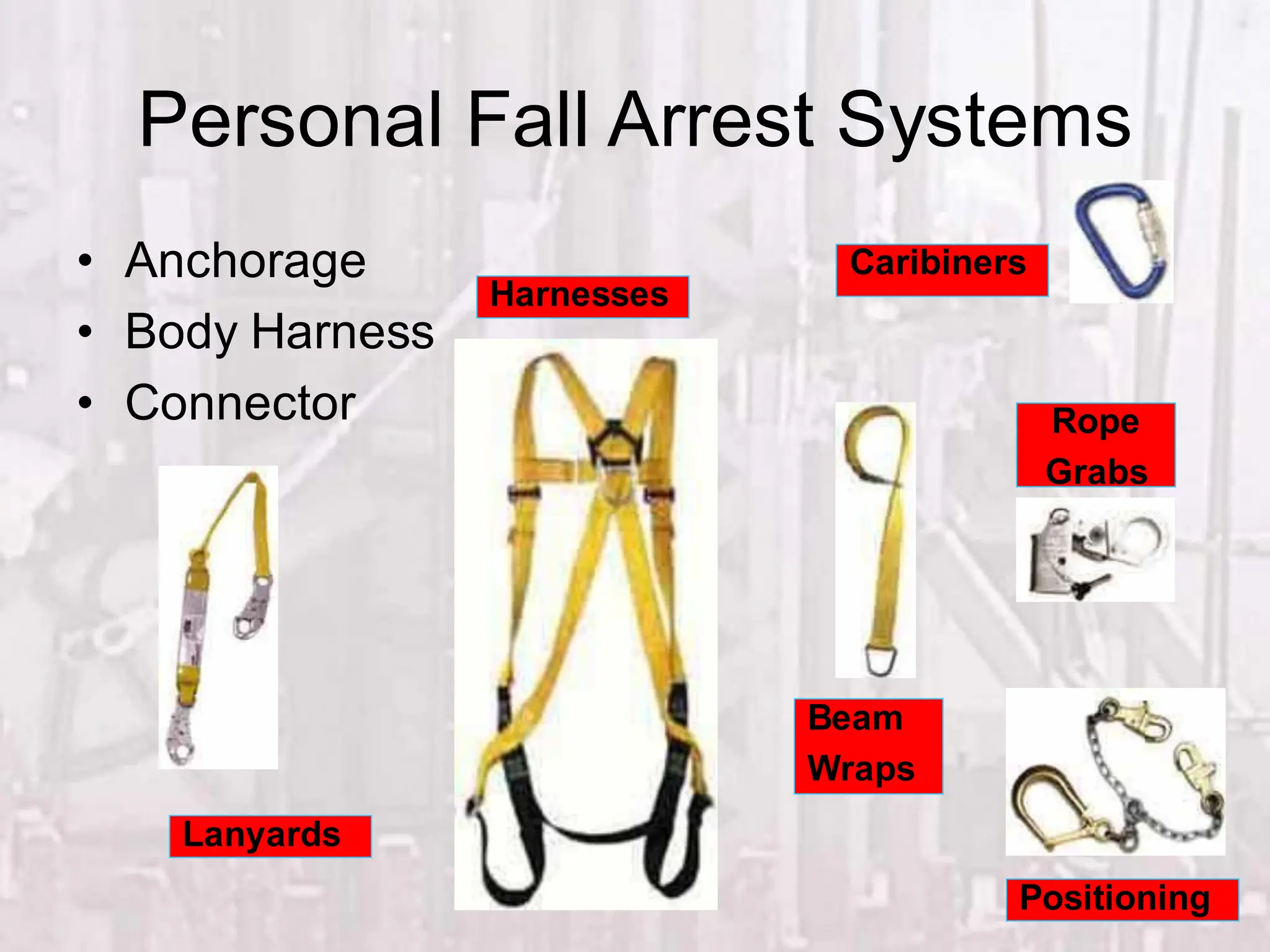

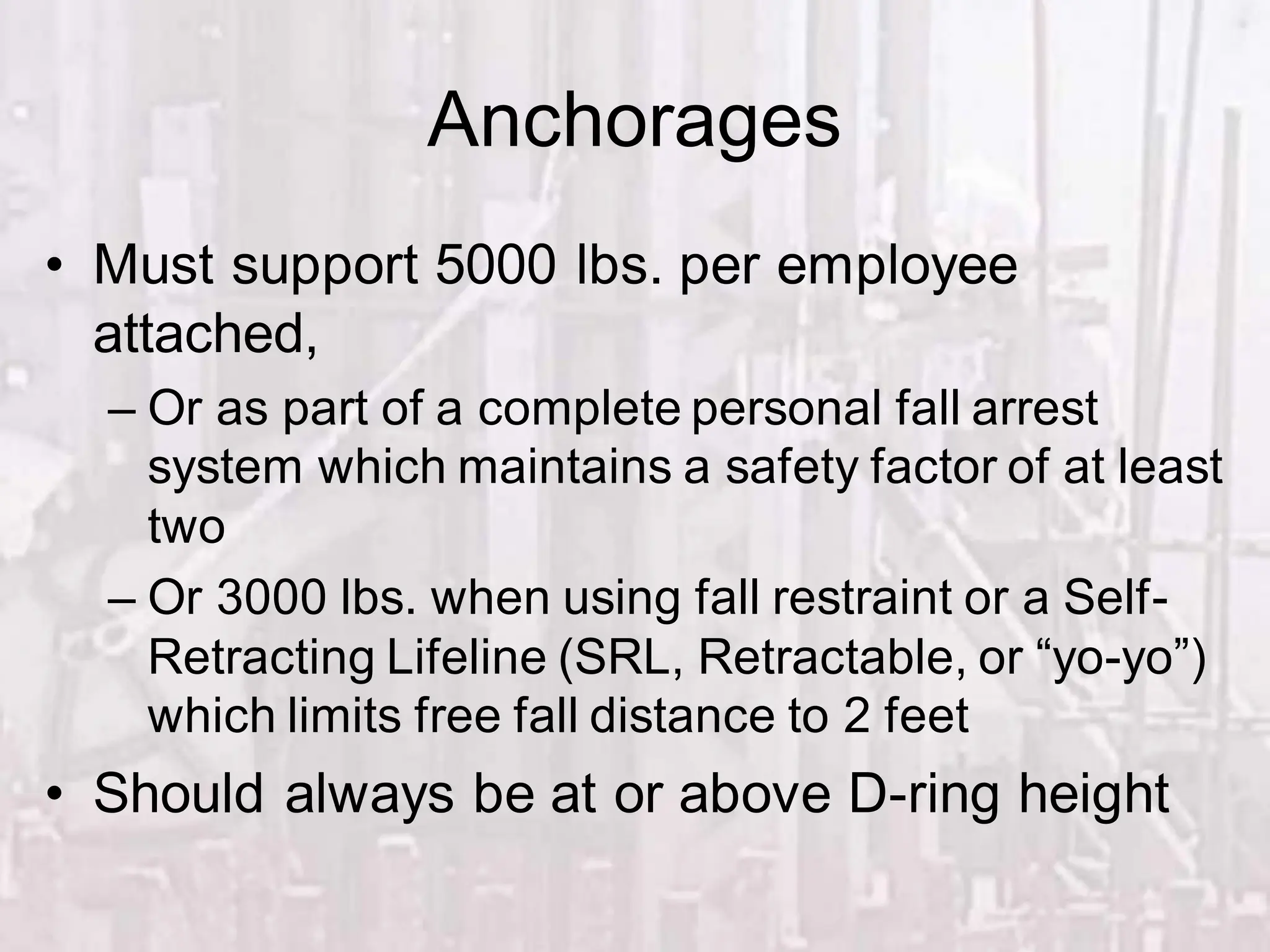

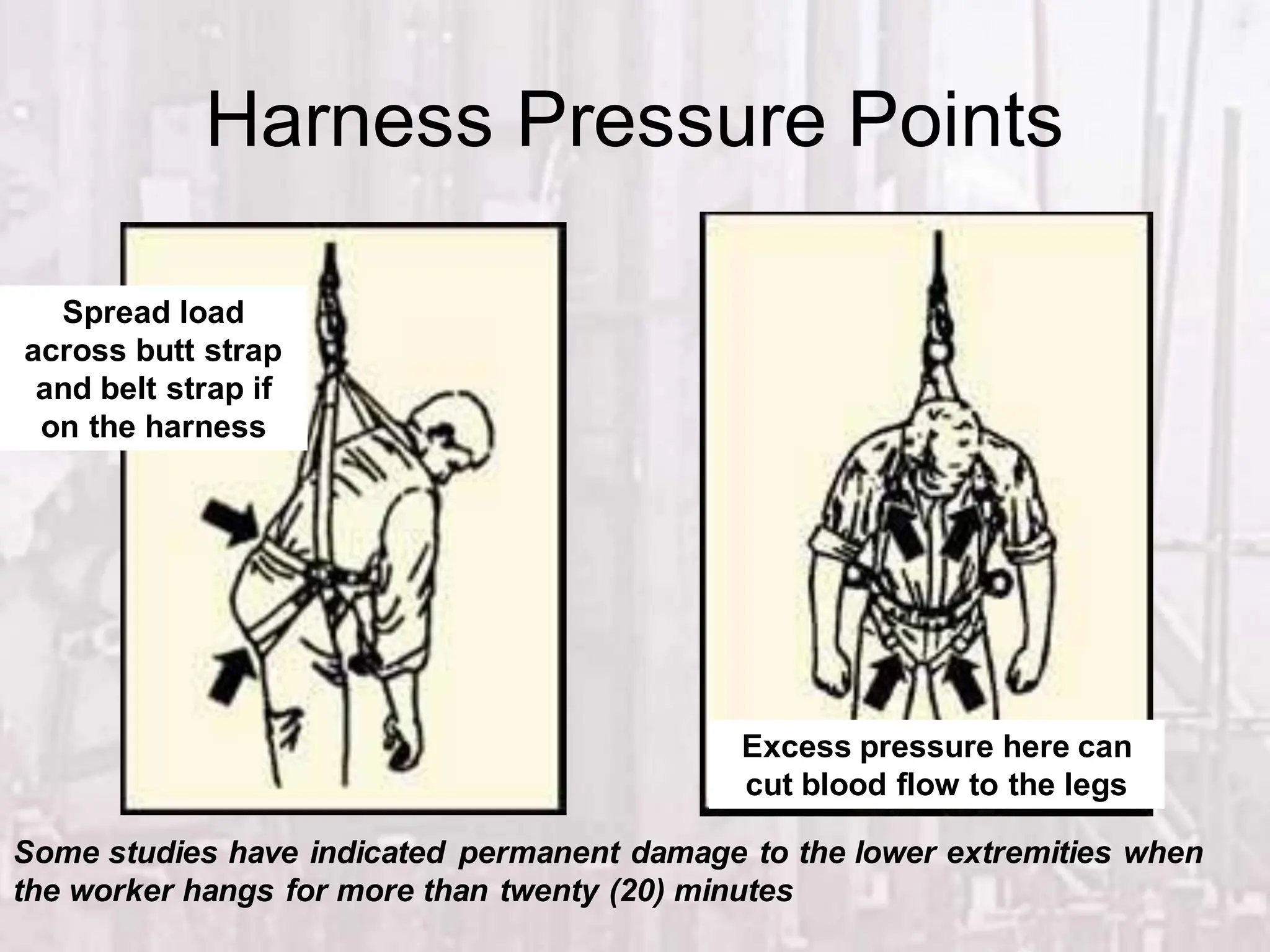

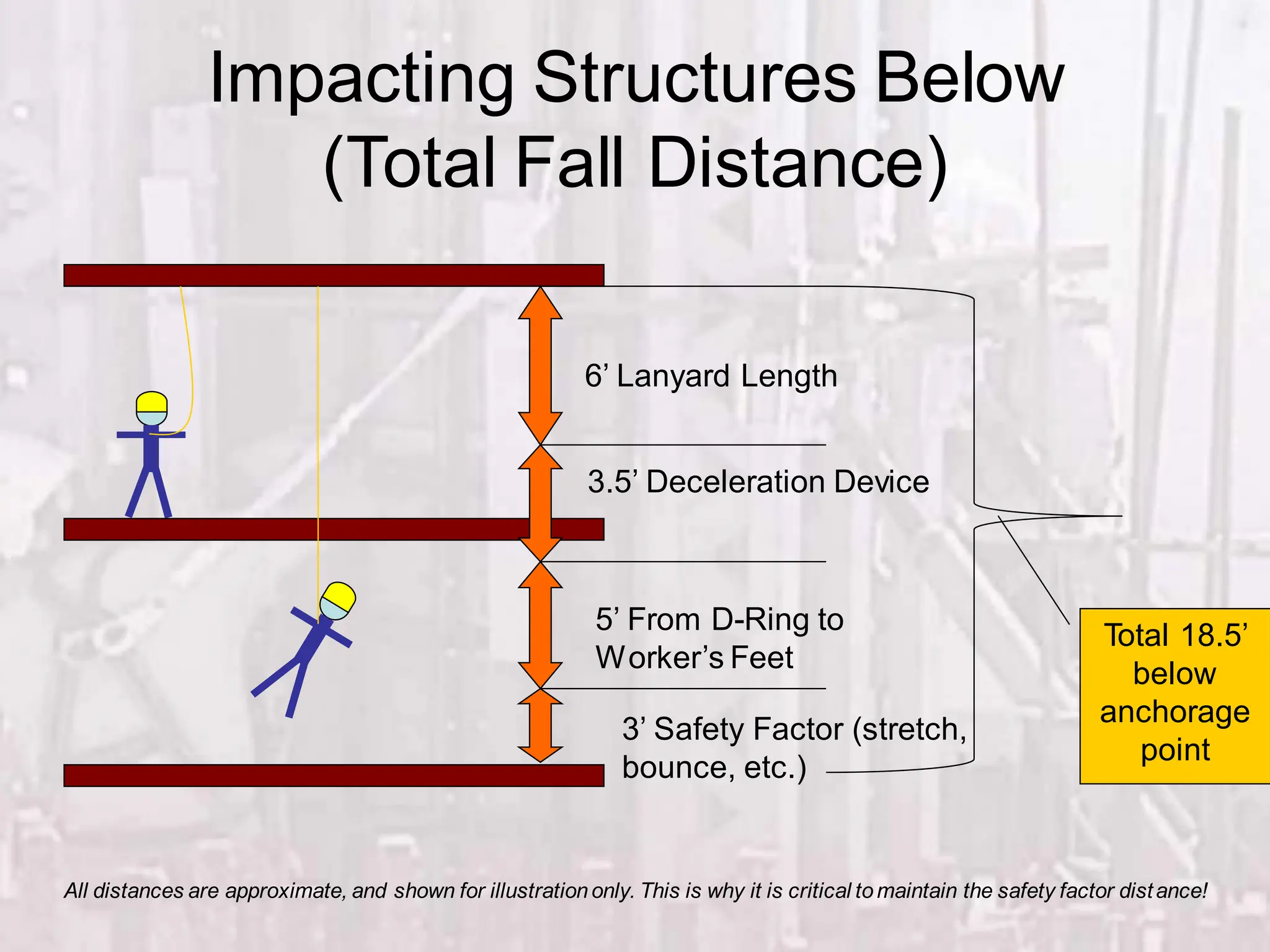

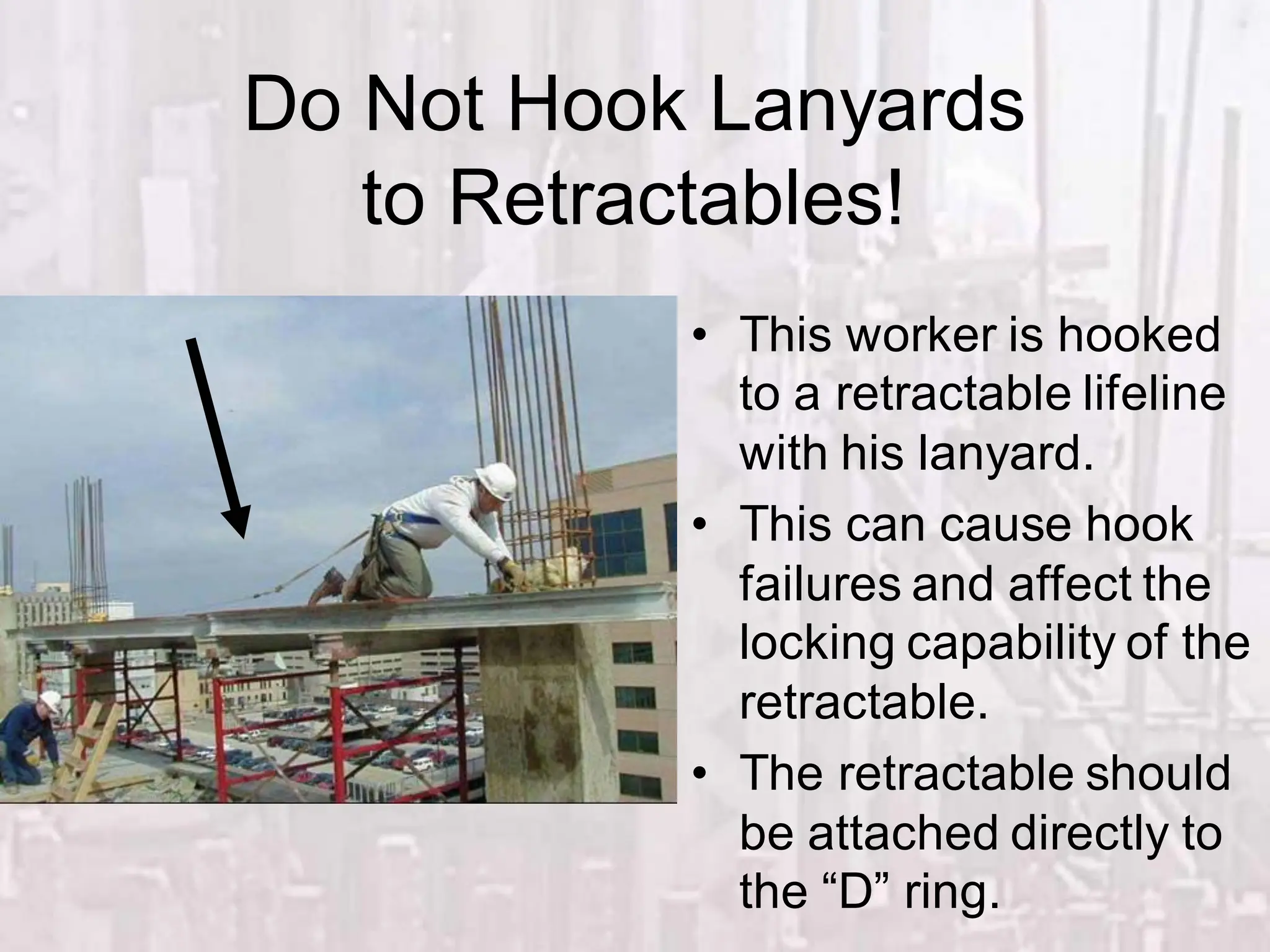

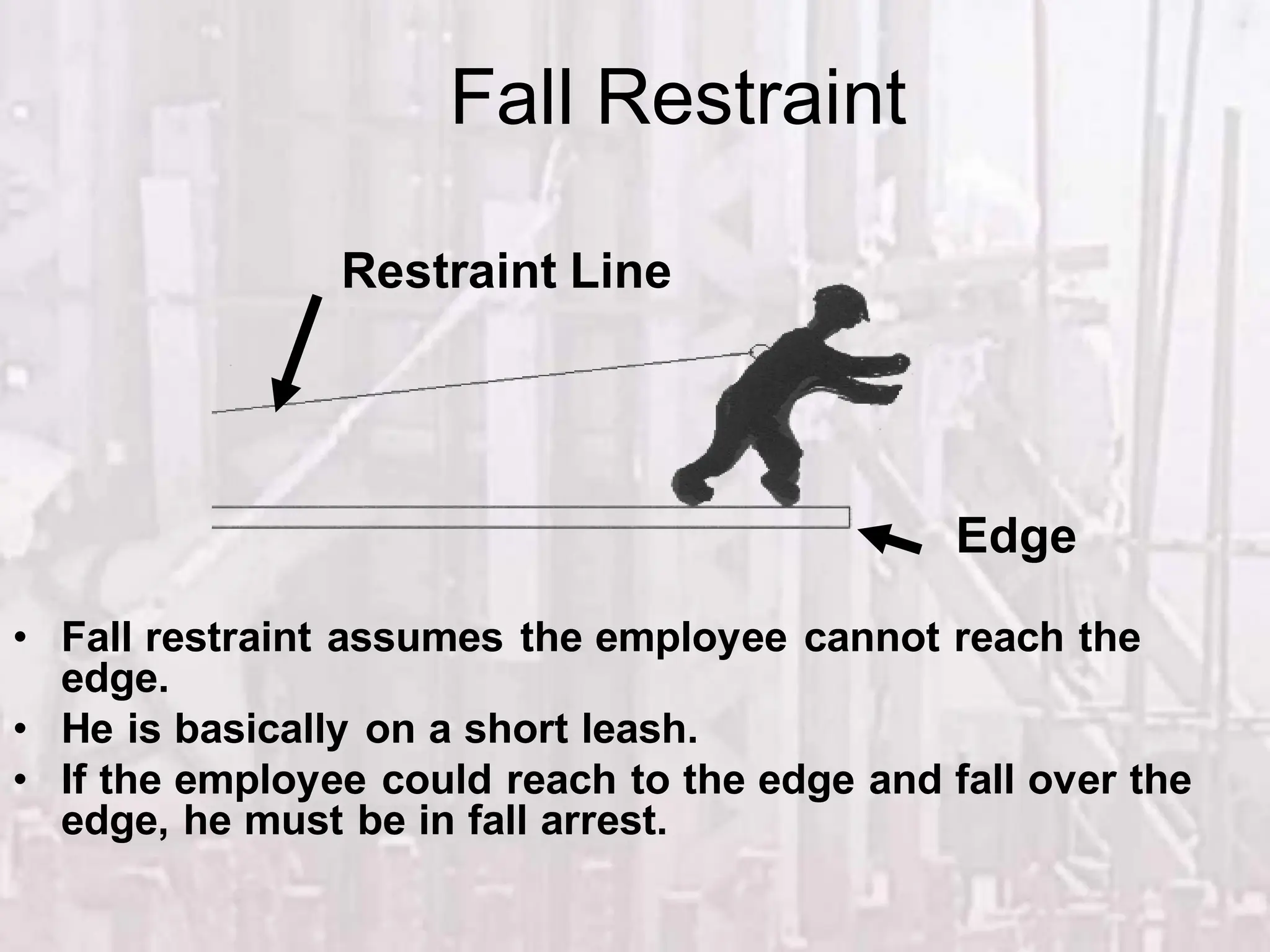

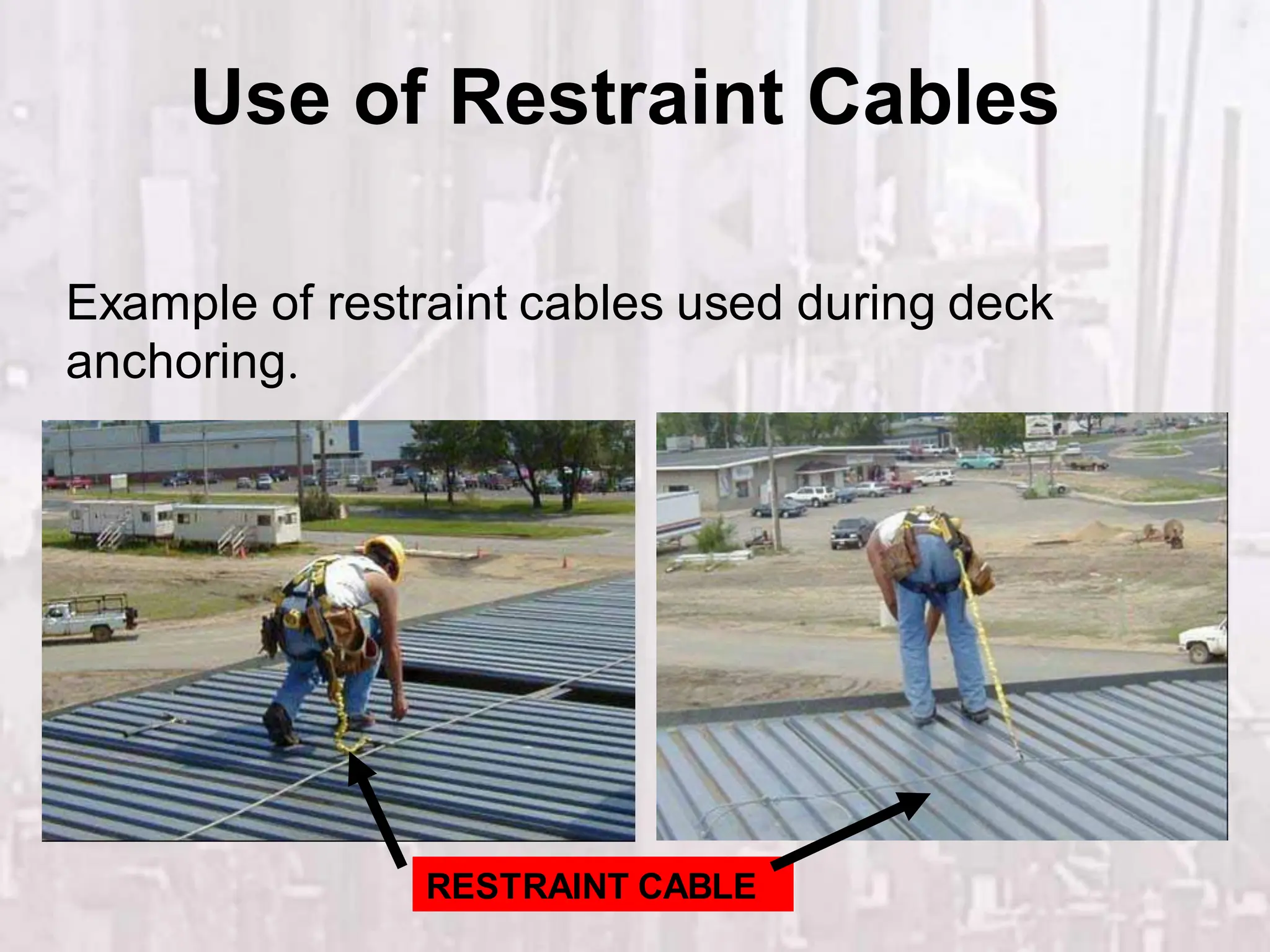

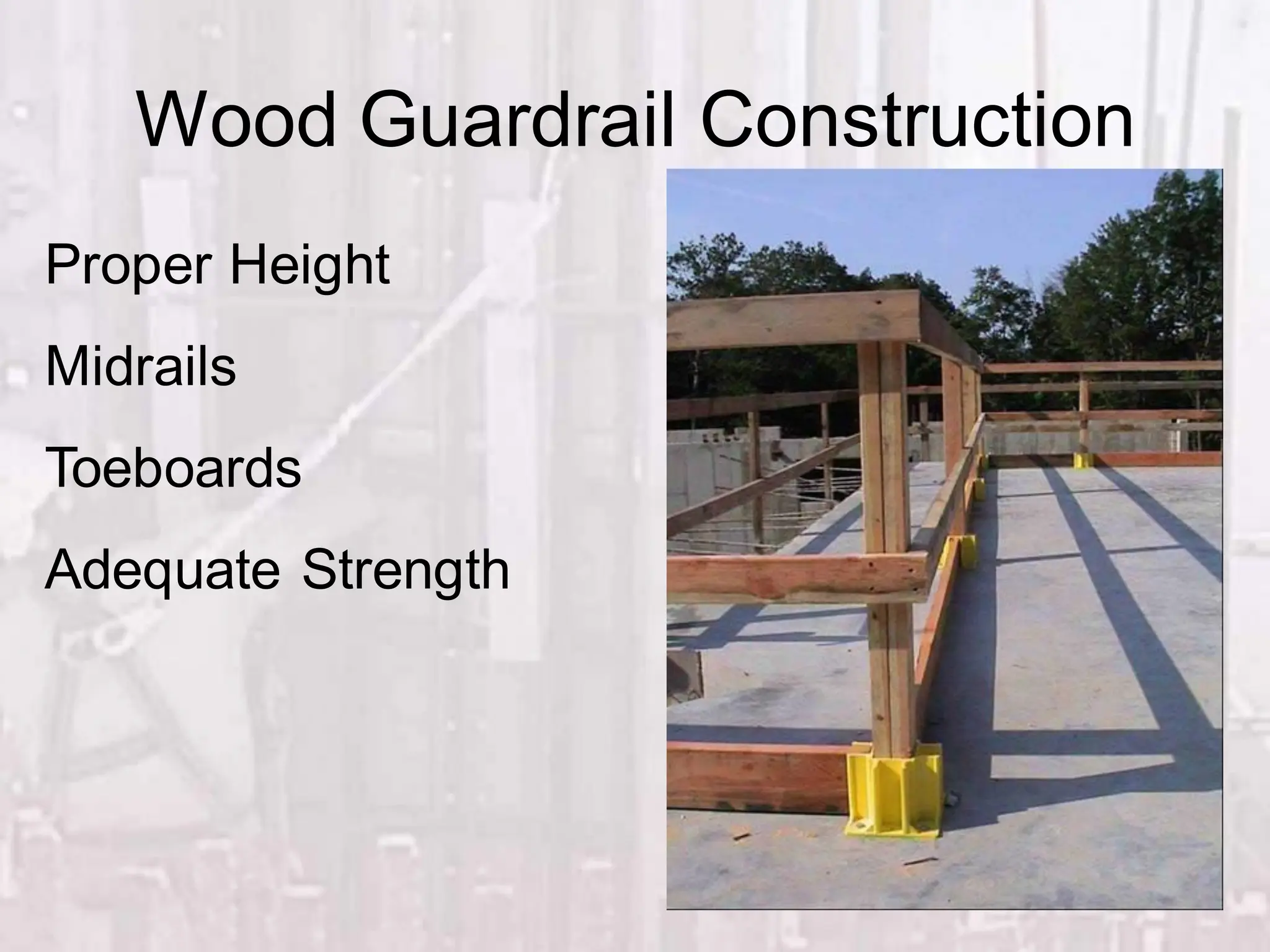

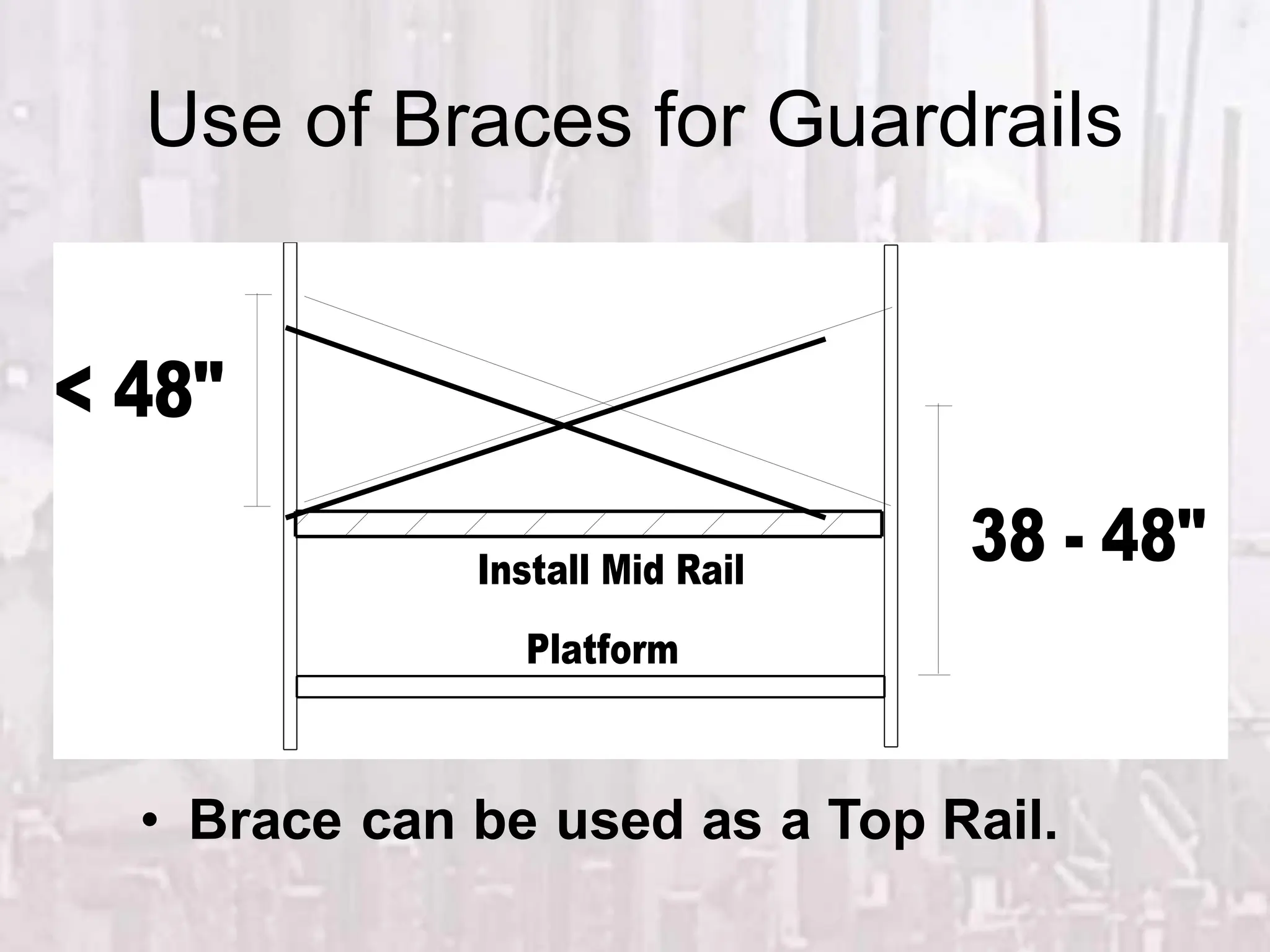

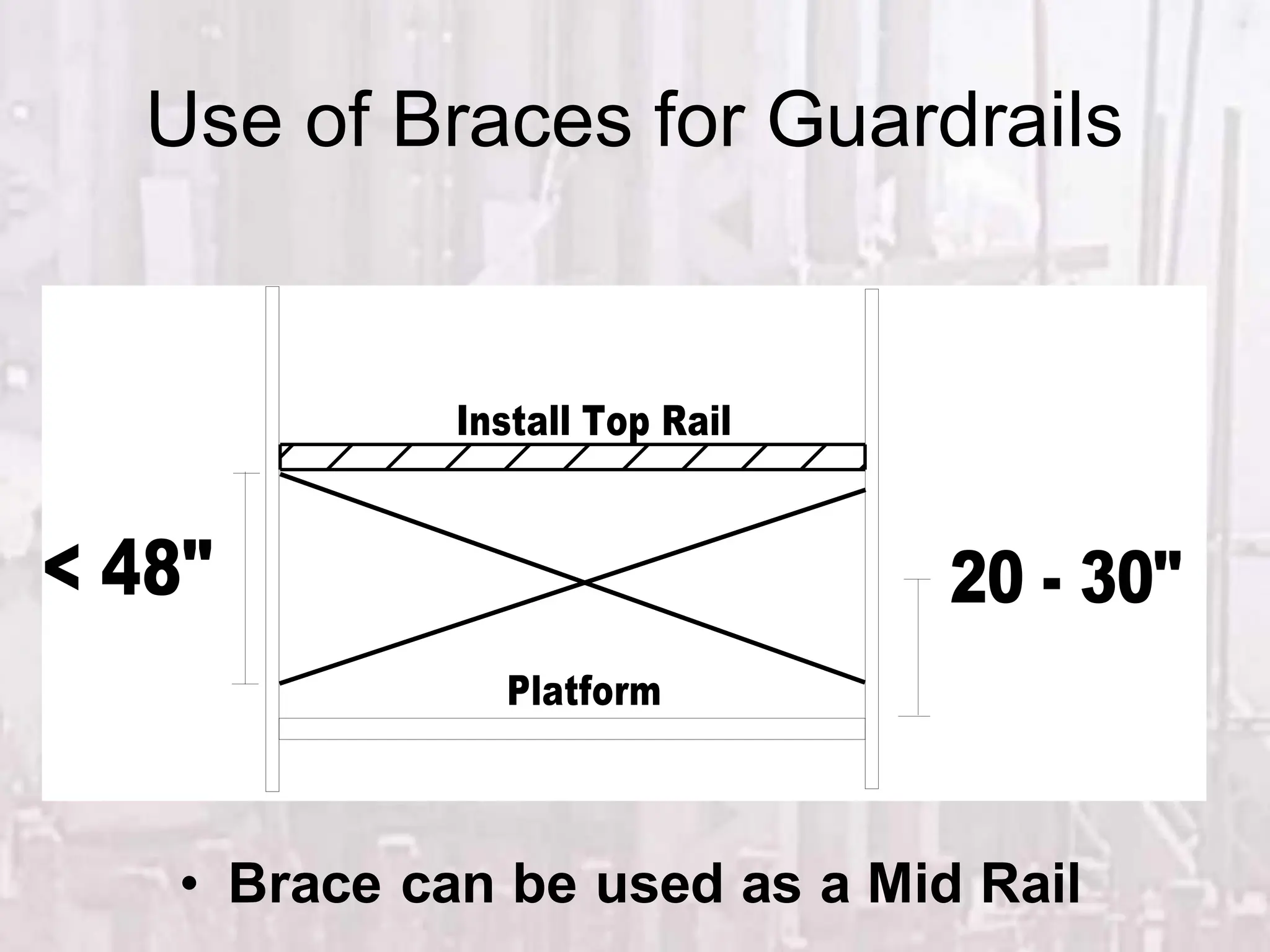

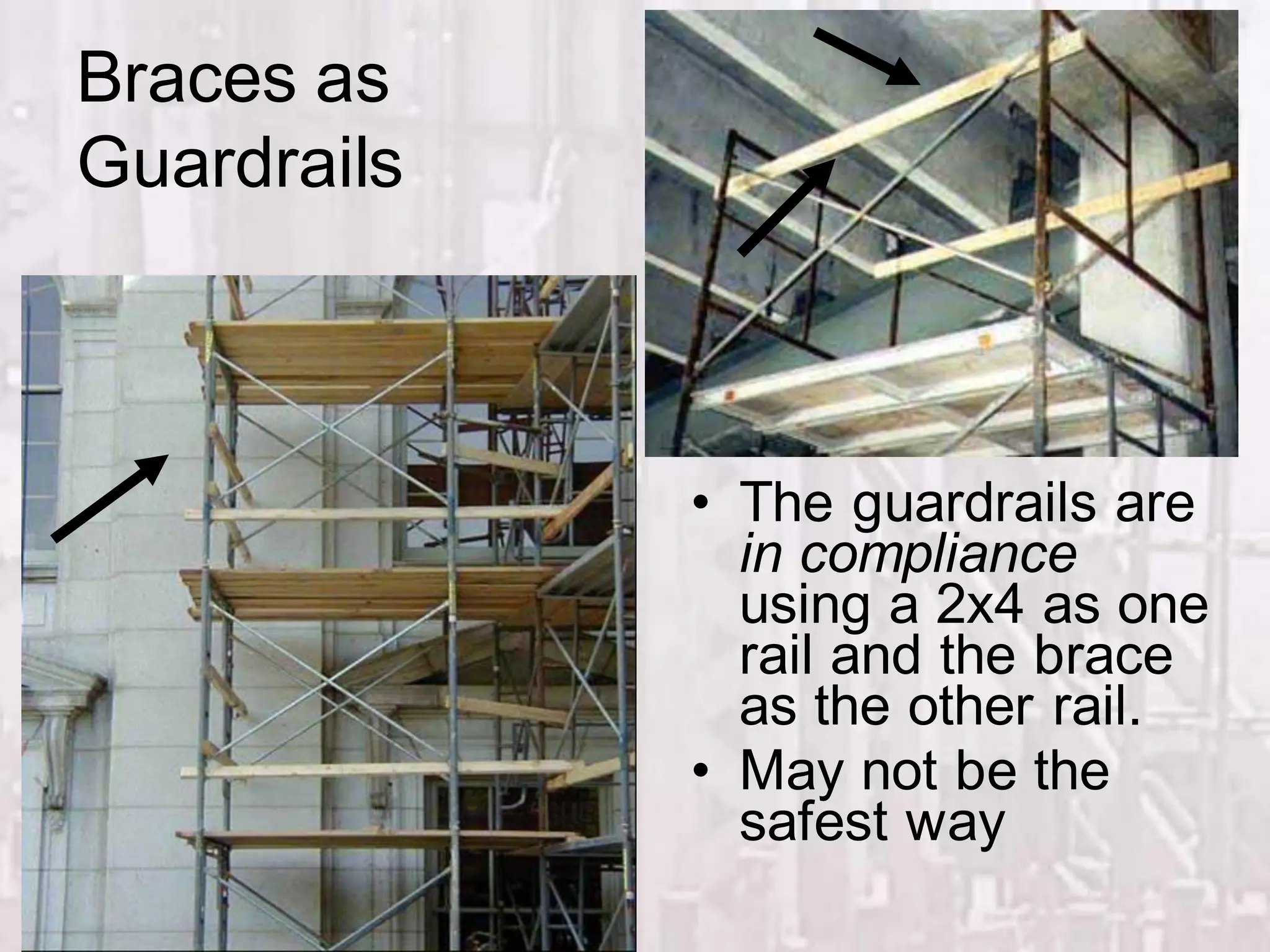

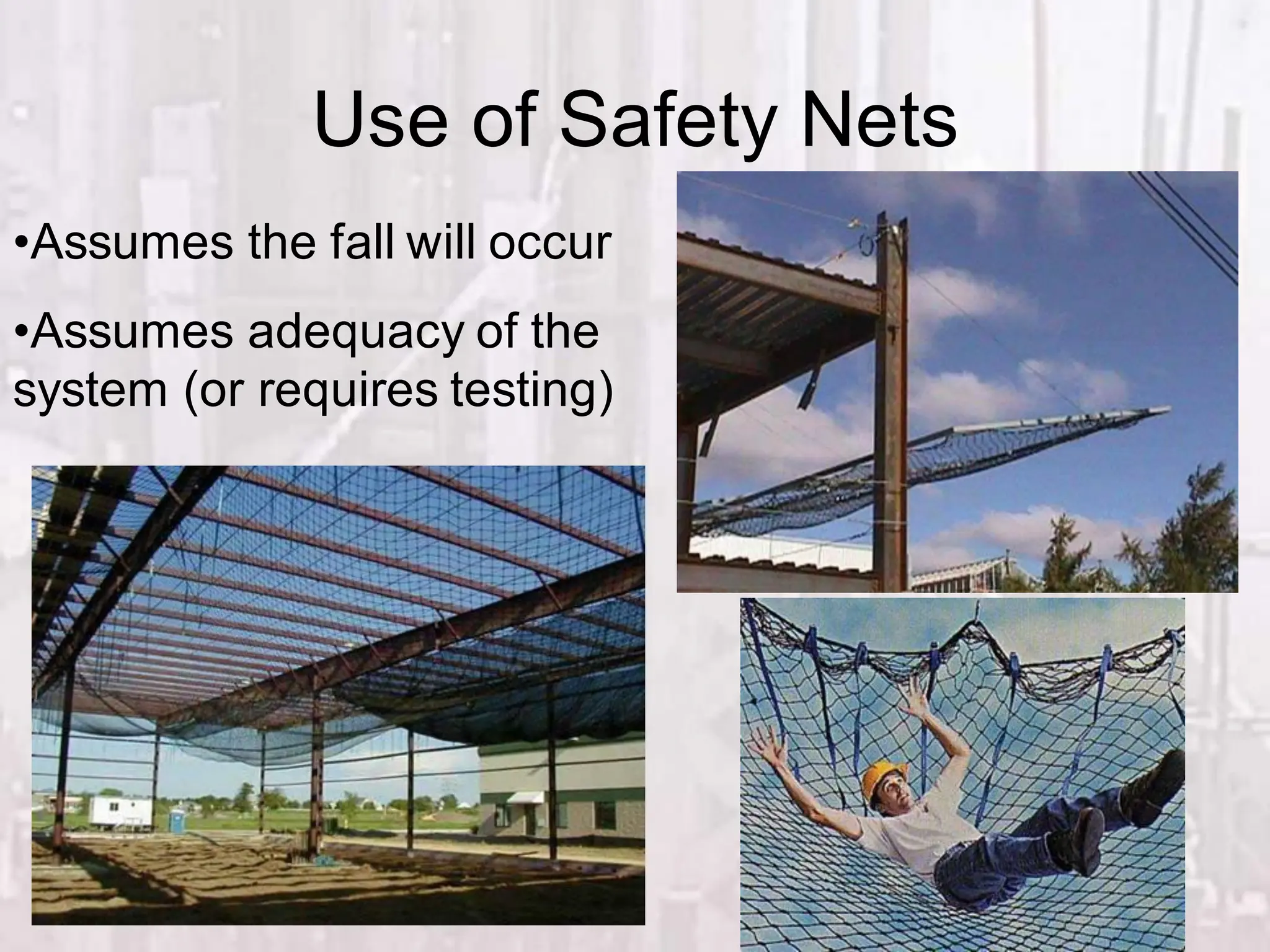

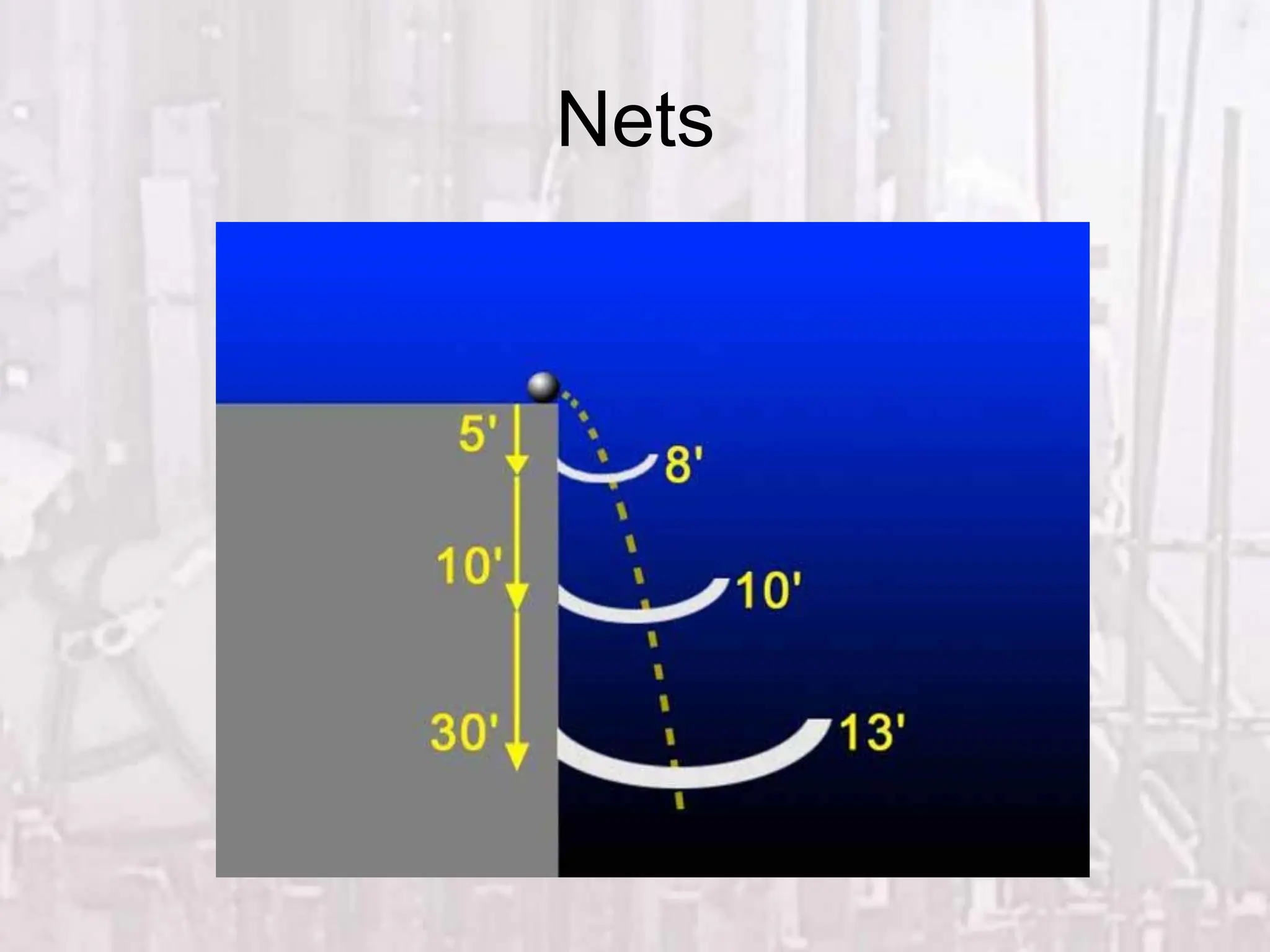

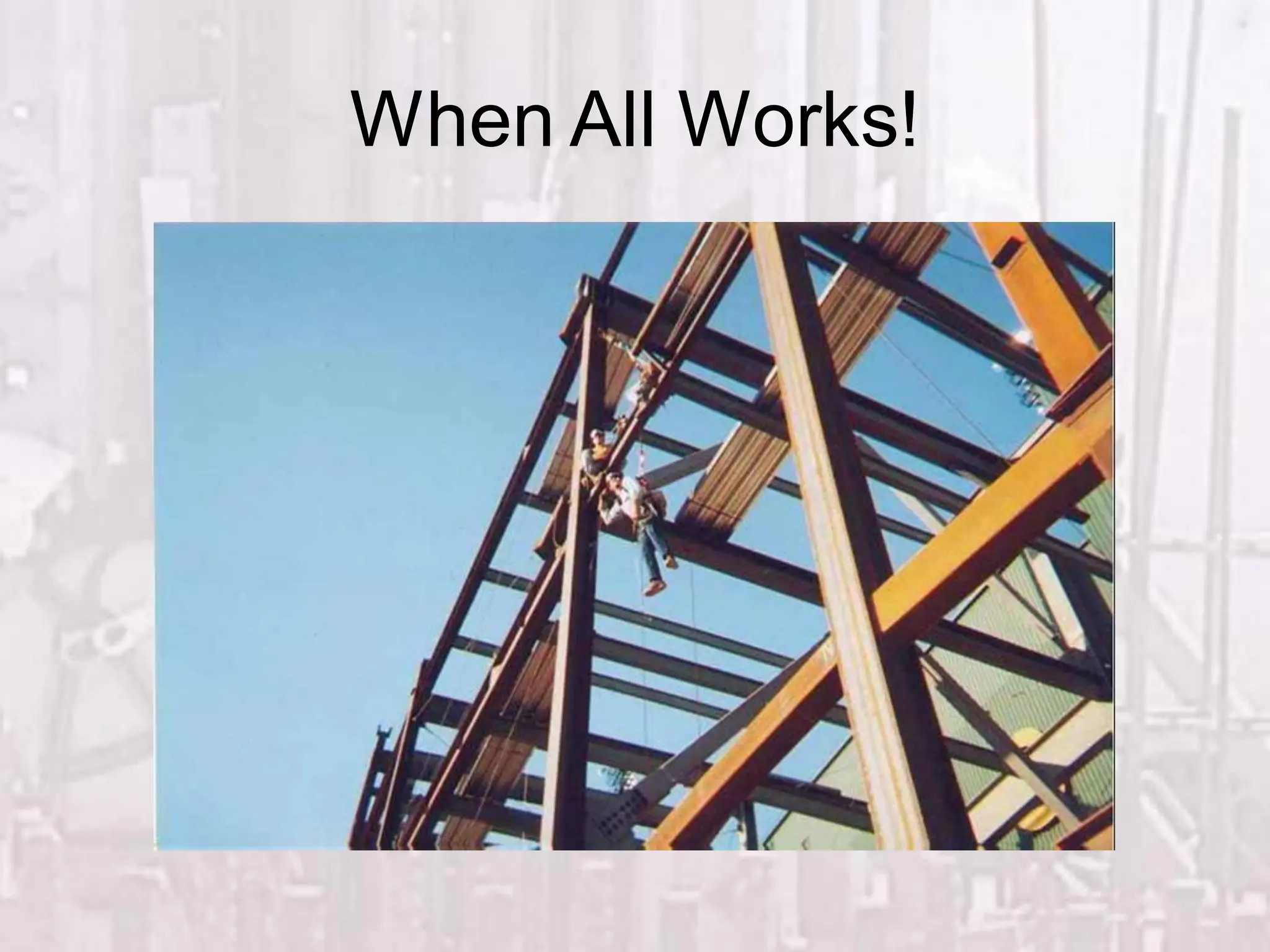

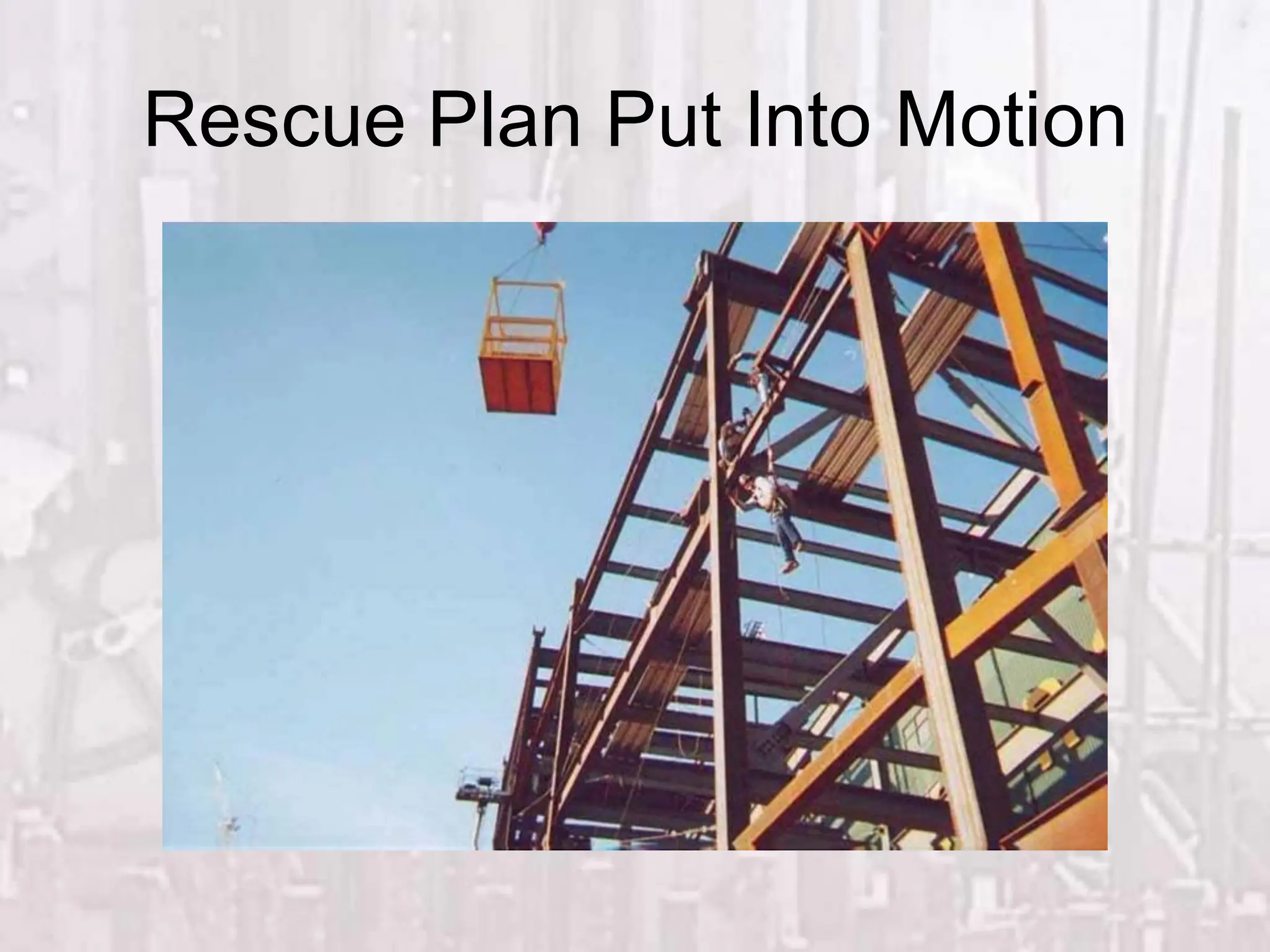

This presentation on fall protection systems highlights the necessity of fall protection in the construction industry to prevent fatalities from falls, which are a leading cause of on-site deaths. It discusses various fall protection methods and best practices for planning, implementing, and maintaining safety measures tailored to specific situations. The document also emphasizes the importance of training workers and the need for continuous evaluation of fall protection systems to ensure their effectiveness.