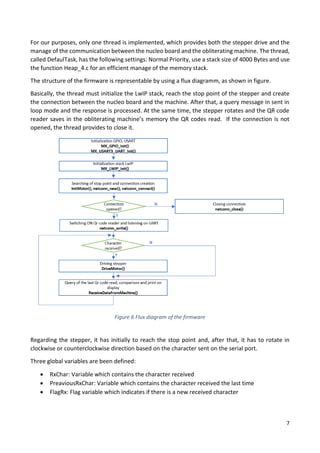

This document describes a testing tool for an automated ticketing system. The tool uses a stepper motor controlled by a microcontroller to vary the height of QR codes being scanned by an obliterating machine. The microcontroller firmware implements TCP/IP communication using LwIP to query the machine and check the scan results. It initializes the stepper motor driver, establishes the network connection, and enters a query-response loop to test the machine's performance at different code heights.