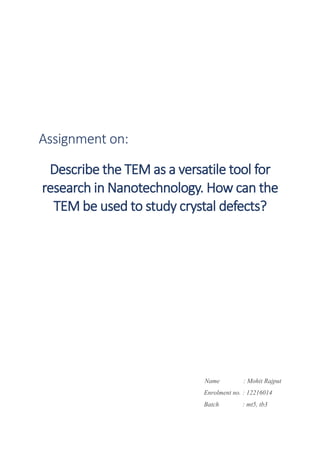

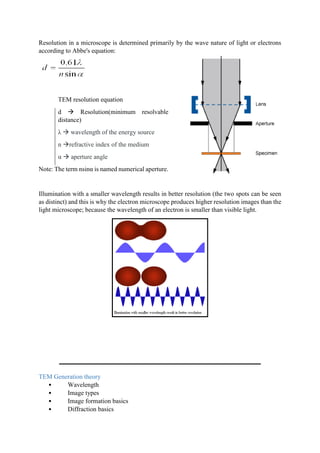

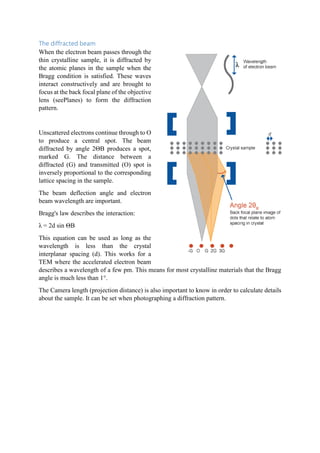

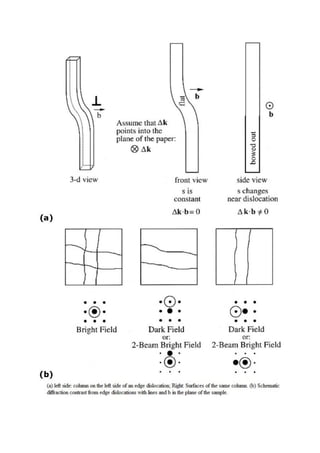

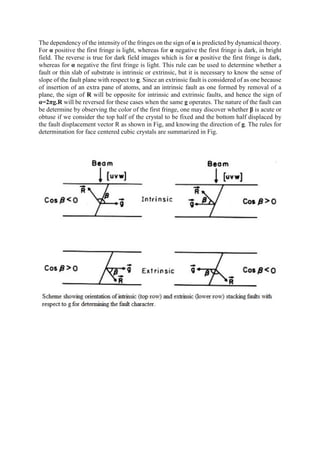

The document discusses the role of Transmission Electron Microscopes (TEM) in nanotechnology, highlighting their importance in characterizing materials at the nanoscale, particularly in semiconductor research. It explains how TEM is utilized to study crystal defects through high-resolution images, revealing intricate details about crystal structures and orientations. The document also details the operational principles, benefits, and various image types produced by TEM, emphasizing its advantages over traditional microscopy.