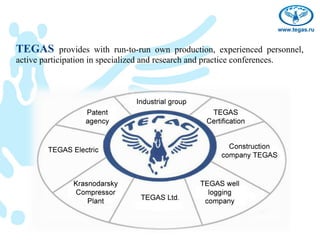

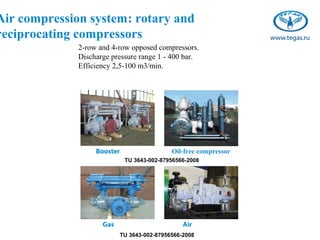

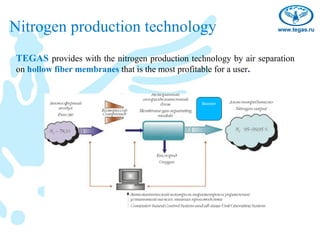

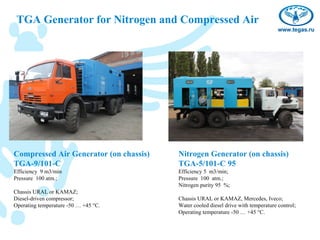

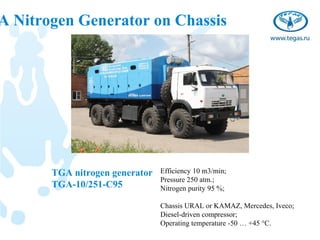

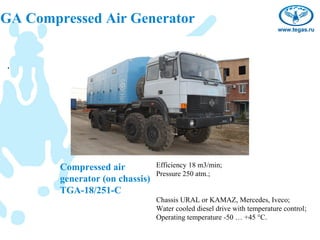

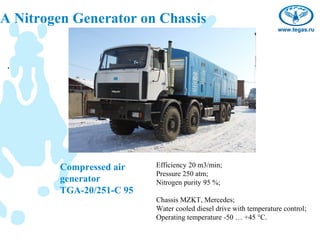

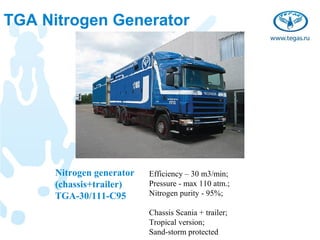

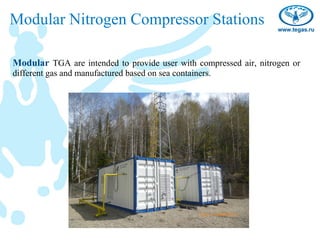

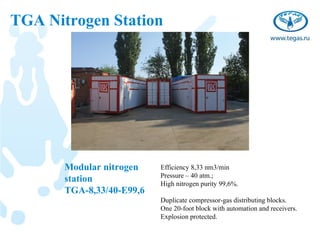

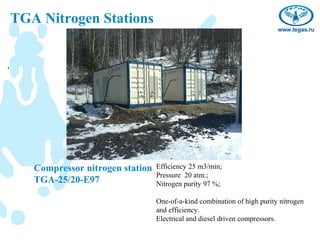

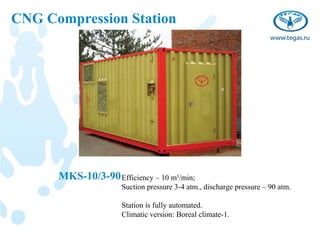

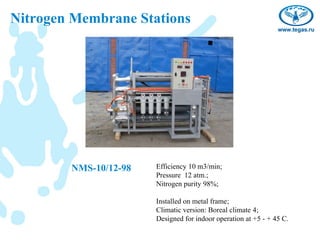

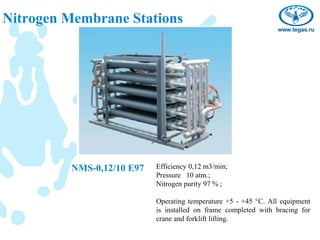

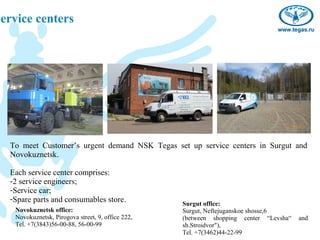

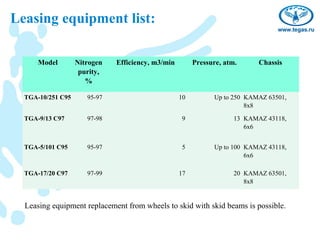

Tegas Industrial Group specializes in providing nitrogen production technology and air compression systems, offering equipment for lease and service, including various compressors and modular nitrogen stations. Their products are designed for high efficiency and reliability, featuring advanced automation and safety systems. The company also guarantees comprehensive support with a dedicated service team and several service centers to meet customer needs.