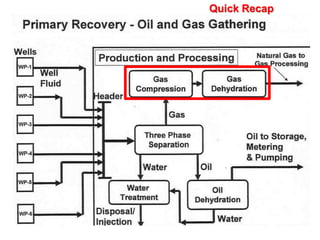

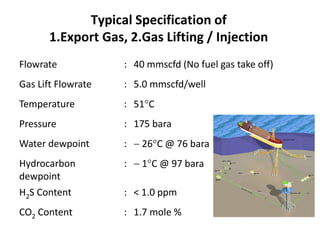

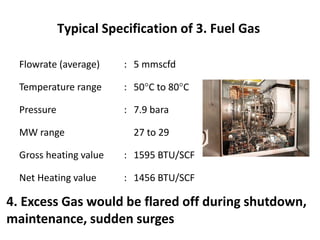

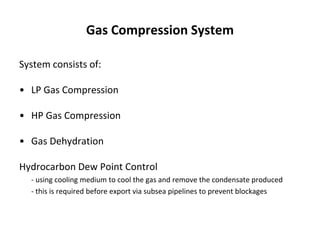

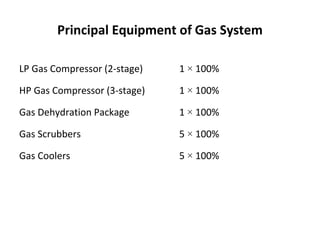

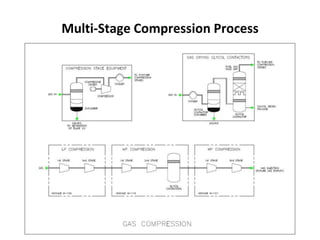

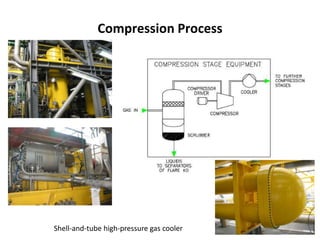

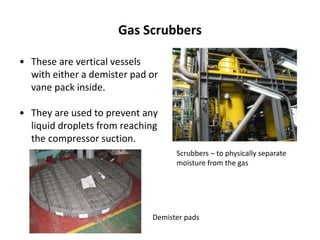

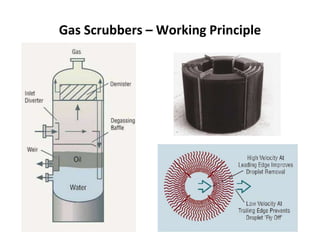

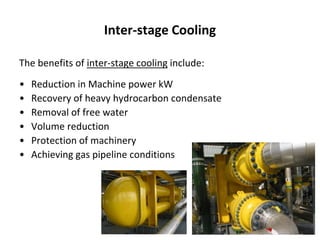

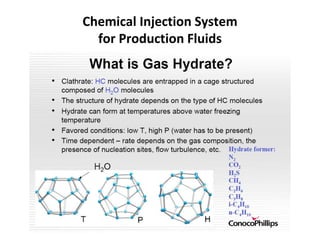

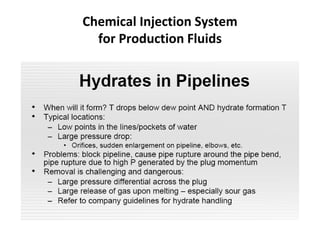

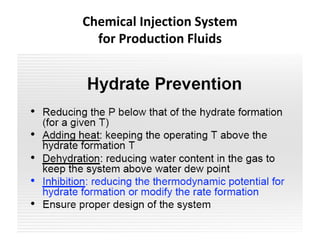

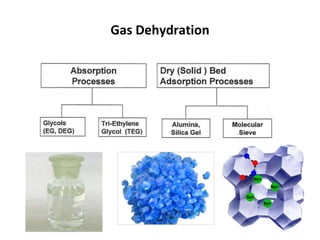

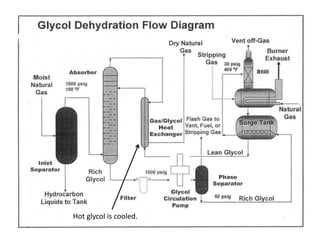

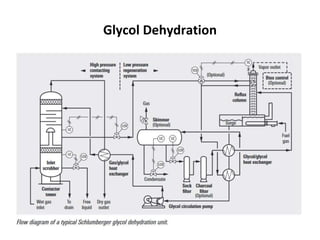

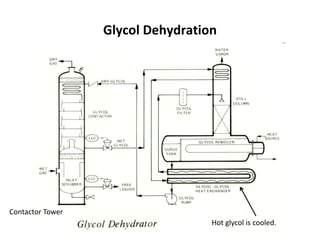

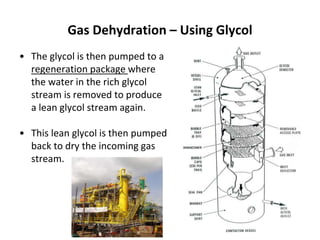

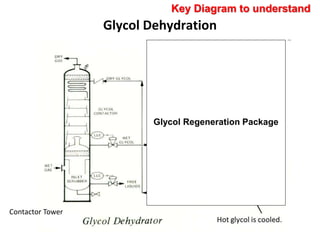

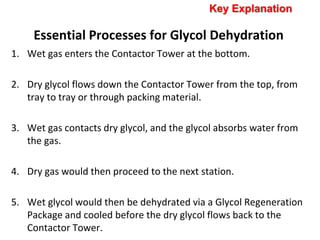

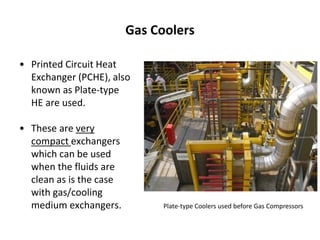

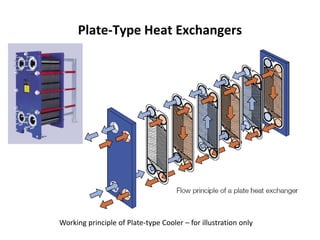

The document discusses offshore gas production and processing systems. It explains that associated gas from an FPSO can be 1) exported, 2) used for gas lifting/injection, 3) used as fuel gas, or 4) flared during shutdowns. It then describes the multi-stage compression and cooling processes the gas undergoes, including scrubbing, dehydration using glycol or molecular sieves, and cooling to remove condensates before export via pipelines. Hydrates are gas-water compounds that can form and block pipes, but chemical injection or dehydration can prevent their formation.