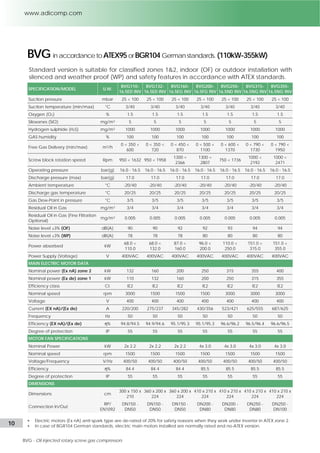

This document provides technical details about oil-injected rotary screw gas compressors and treatment systems for biogas upgrading from Adicomp S.r.l. It describes Adicomp's experience and leadership in biogas compression and treatment. Their systems can compress biogas up to 2000Nm3/h and remove contaminants like water, dust, siloxanes and oil to produce bio-methane that meets grid injection standards. The document provides details on the compressor components, gas and oil circuits, cooling systems, controls and optional equipment available.