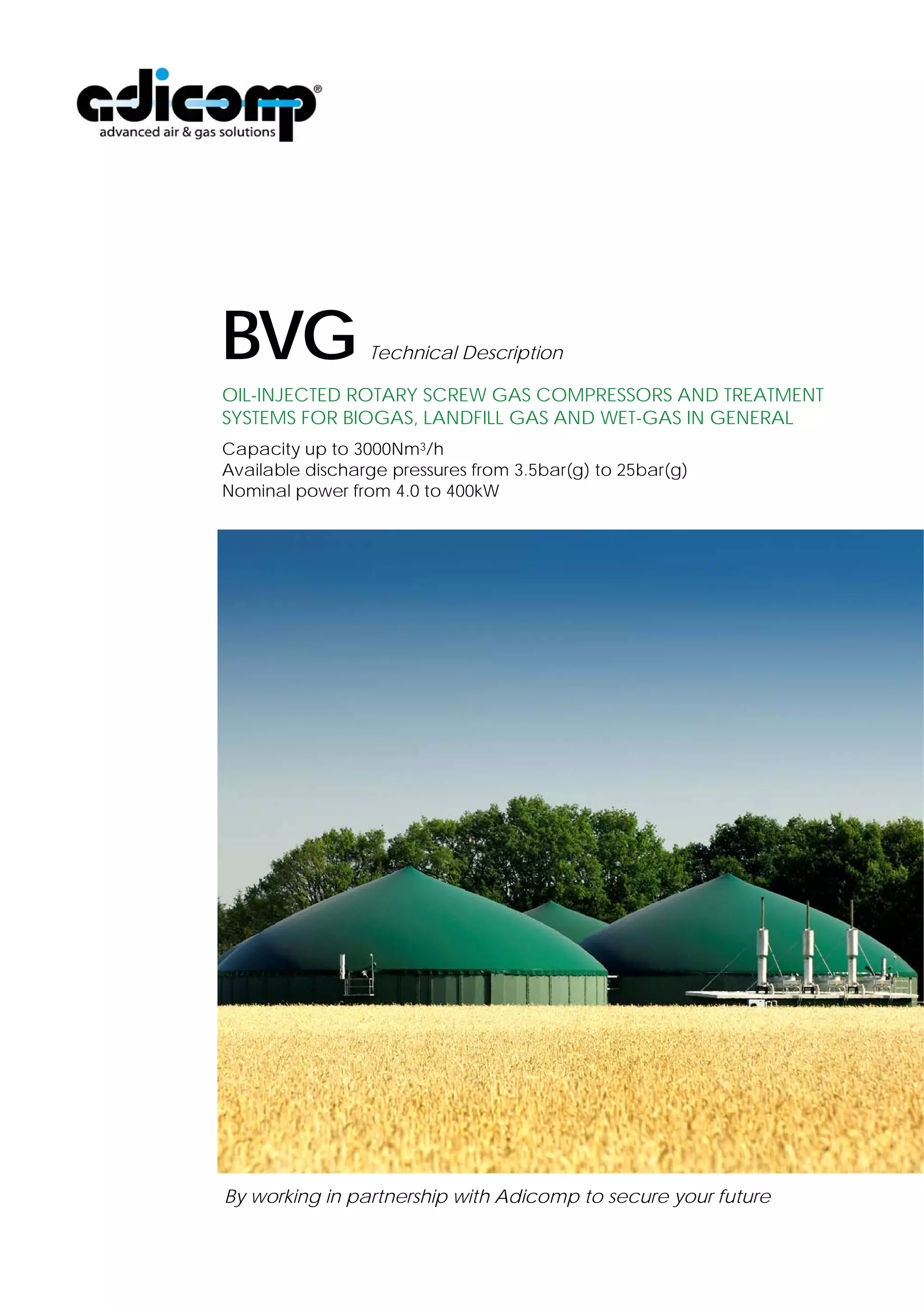

The document provides technical details about Adicomp's oil-injected rotary screw gas compressors and treatment systems for biogas, landfill gas, and other wet gases. Key points include:

- Capacity ranges from 3000Nm3/h up to pressures of 25bar(g) with motor power from 4-400kW.

- Adicomp has over 15 years of experience supplying hundreds of biogas, landfill gas, and other gas compression and treatment installations around the world.

- The compressors and treatment systems are compact, quiet, and suitable for various industrial sectors in temperature ranges from -20°C to 40°C.

- Adicomp considers itself a leader