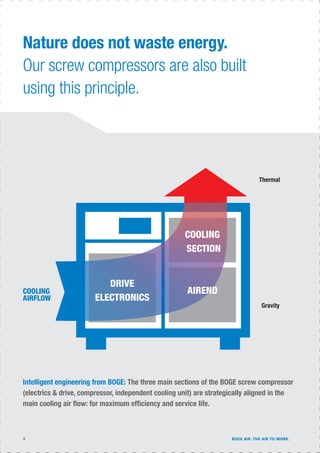

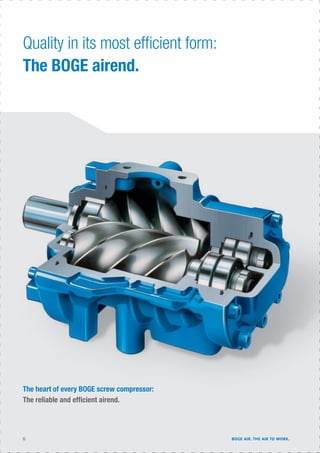

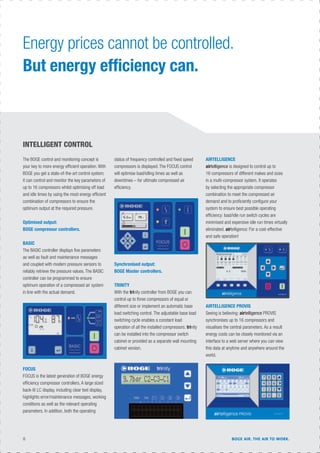

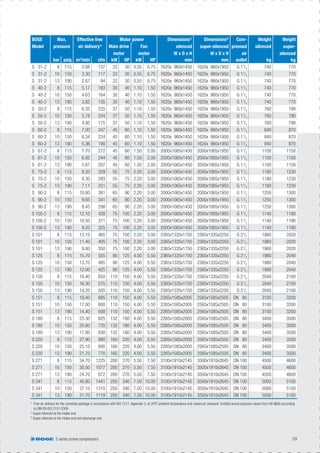

BOGE manufactures screw compressors for industrial and commercial use. Their compressors have stood the test of time for over three decades, known for their reliability, efficiency, and quality as a result of German engineering. BOGE offers a modular design which allows for flexible combinations of compressors, receivers, dryers, and controls to meet customers' compressed air needs. Their compressors range in power from 2.2 kW to 480 kW.