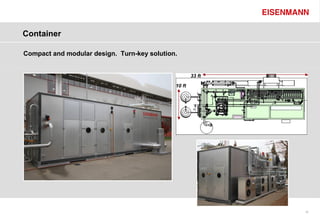

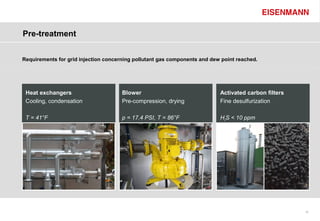

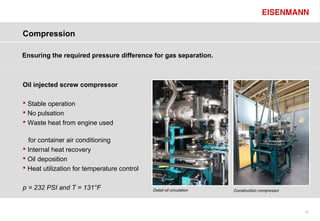

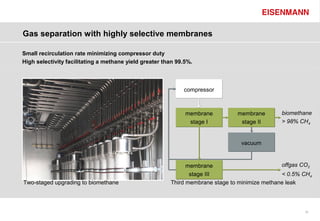

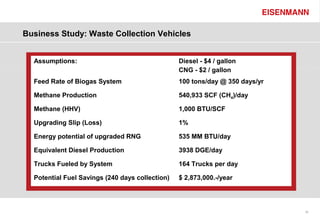

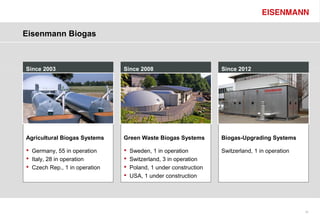

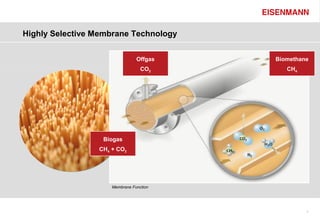

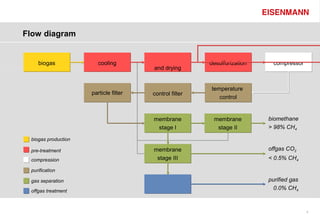

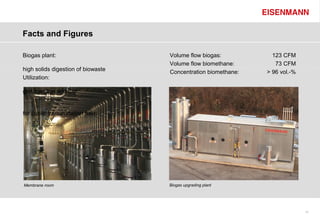

The document discusses biogas upgrading to renewable natural gas (RNG) using membrane technology. It provides an overview of biomethane incentives, membrane upgrading technology, and a case study of a membrane upgrading system installed at a biogas plant in Switzerland. The system uses highly selective membranes in a multi-stage process to upgrade biogas to over 96% methane, which is then injected into the natural gas grid.

![Measurement Data

Successful test operation in December 2012

Grid injection since January 26, 2013

concentration [vol.-%]

concentration [vol.-

concentration biomethane [vol.-%]

concentration methane [vol.-%]

concentration CO2 [vol.-%]

concentration CO2 [vol.-%]

%]

Dec 3 Dec 4 Dec 5 Dec 6 Dec 7 Dec 3 Dec 4 Dec 5 Dec 6 Dec 7

2012 2012

Biomethane to grid injection: methane > 96 % Offgas to atmosphere: methane leakage < 1.0 %

14](https://image.slidesharecdn.com/biocycle2013-membranetechnology-tg-130409170722-phpapp02/85/Membrane-Technology-Biocycle-West-Coast-2013-14-320.jpg)