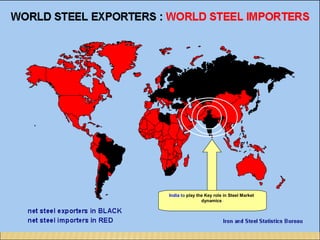

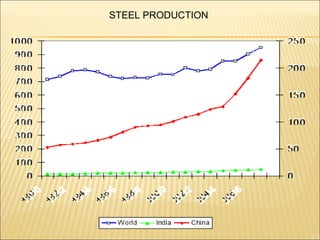

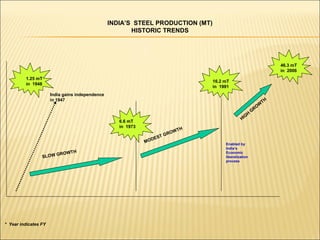

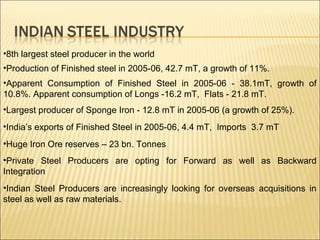

1. The document discusses capacity planning for the steel industry in India. It analyzes historical production trends, current strengths and weaknesses, opportunities and threats.

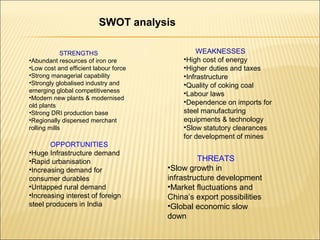

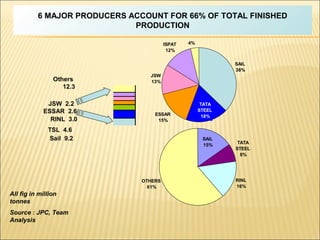

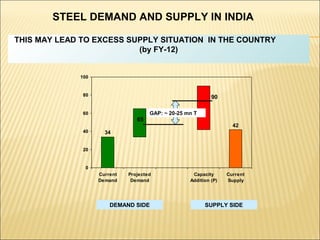

2. A SWOT analysis is presented for the steel industry. Key players like SAIL, Tata Steel, and JSW Steel are discussed. Current demand and supply projections indicate a potential excess supply situation by 2012.

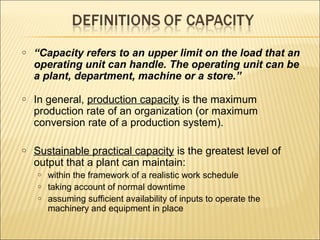

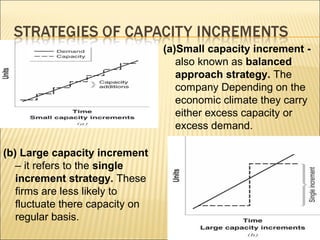

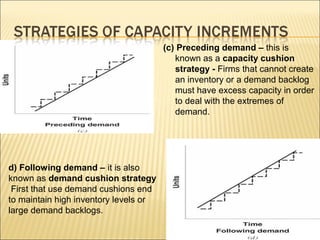

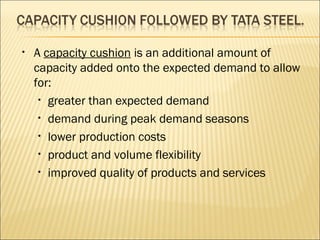

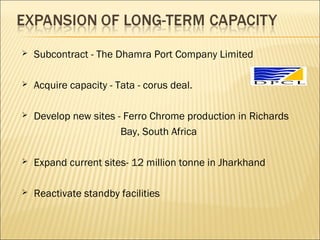

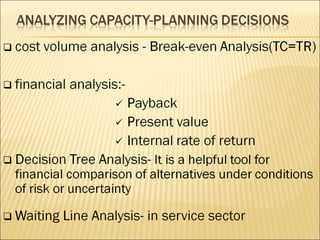

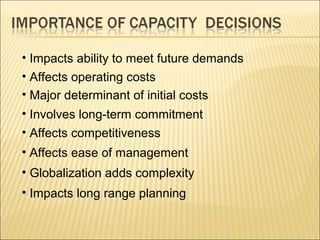

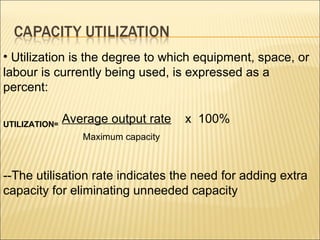

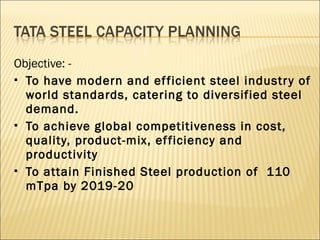

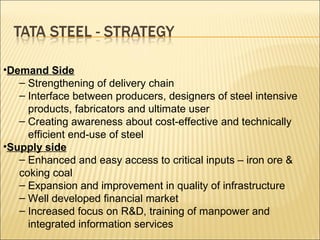

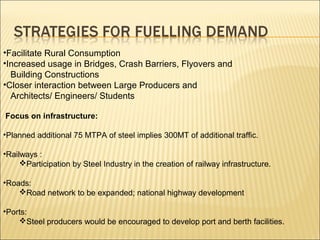

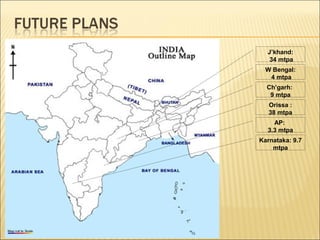

3. Strategies for capacity planning are outlined, including expanding existing sites, developing new sites, acquiring other companies, and utilizing subcontracting. The objectives of the Indian steel industry are defined as achieving global competitiveness and a production target of 110 MTPA by 2019-20.