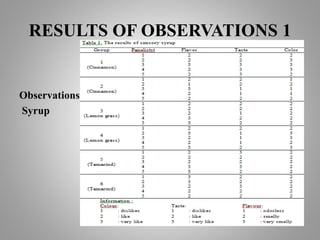

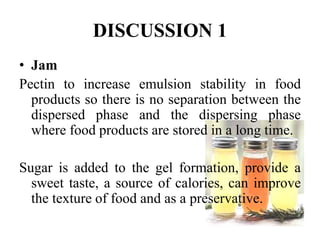

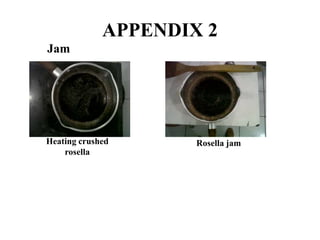

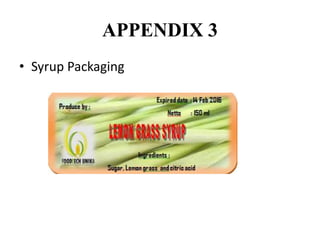

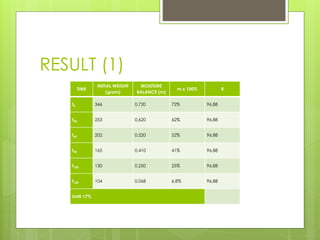

The document describes experiments conducted to make jams, syrups, and tea bags from herbal ingredients. It discusses the materials and methods used, results of sensory analysis, and packaging of the finished products. Key findings include that panelists generally preferred rosella jam from group 2 and lemongrass syrup from group 3. The drying rate of herbal samples in a solar tunnel dryer depended on factors like the amount and size of the samples.