This document summarizes research on the synthesis and classification of nanostructured materials. It discusses how nanostructured materials can be classified based on their dimensions as zero-dimensional, one-dimensional, two-dimensional, or three-dimensional. Common synthesis methods like hydrothermal/solvothermal and sol-gel techniques are described. The hydrothermal method involves a chemical reaction in a closed system using water or other solvents at high temperature and pressure. The sol-gel method converts a precursor solution into a colloidal solution and gel through hydrolysis and polycondensation reactions. Examples of synthesizing different nanostructured materials like ZnO, Co3O4, ZnS, and TiO2 using these methods are presented from literature.

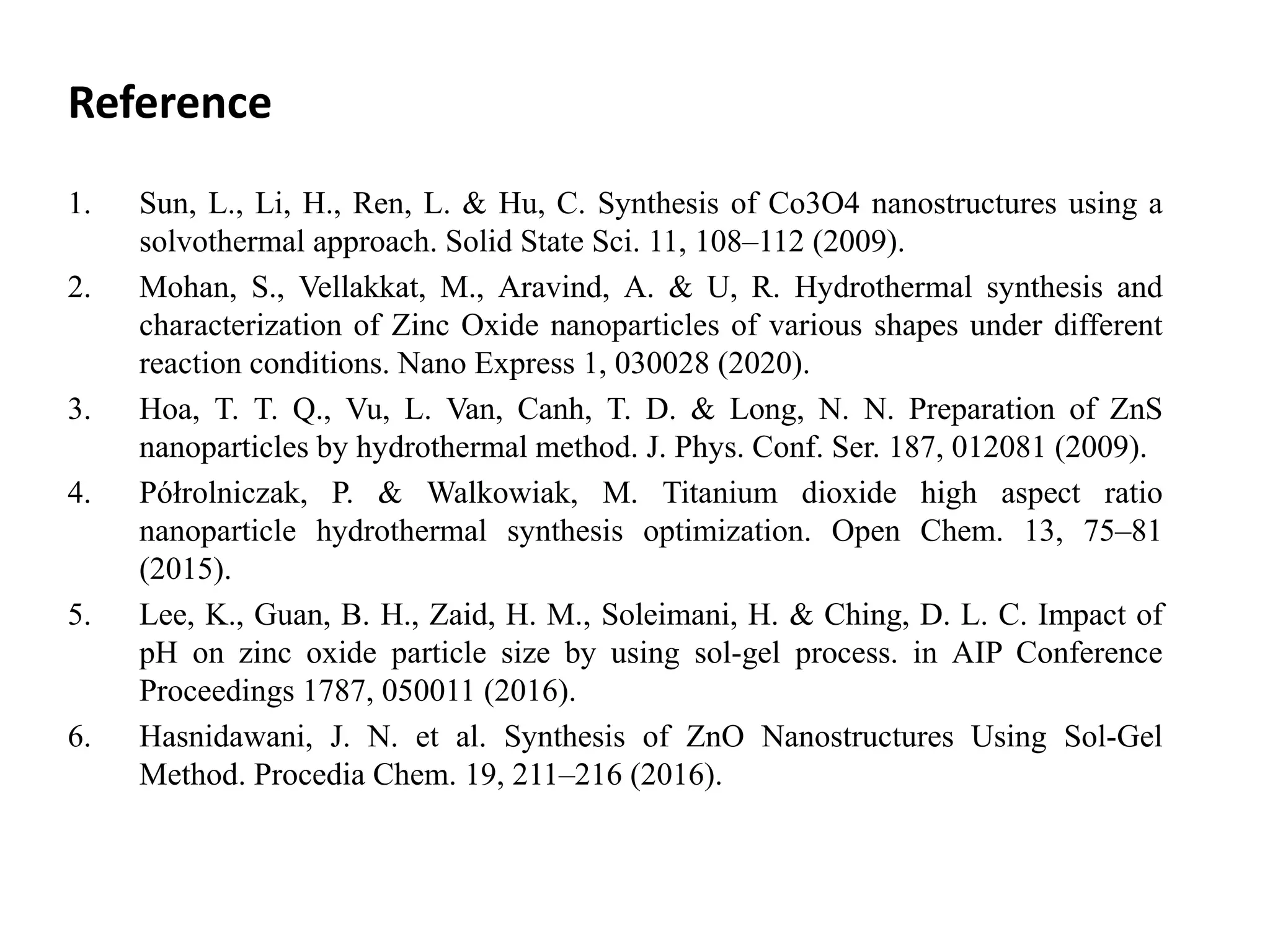

![Yu et al. investigate surfactant's role in tungsten oxide and its hydrates with

different morphologies

Figure 1. SEM image of the synthesized compound under different conditions;

1(a, b). Irregular shape

particles with no

surfactant [50-100nm],

1(c, d). Nanorods structure

in presence of K2SO4

[length-5μm, dimensions-

60-90nm]

1(e, f). Square

shape nanoplates in the

presence of oxalic acid (OA)

[edge length-300nm,

thickness-40nm]

1(g, h). 3D hierarchical

architectures in the presence

of higher OA

Ref: Phys. E Low-dimensional Syst. Nanostructures 79, 127–132 (2016)](https://image.slidesharecdn.com/1ppt-220418110823/75/Synthesis-and-Classification-of-Nanostructured-materials-pptx-6-2048.jpg)

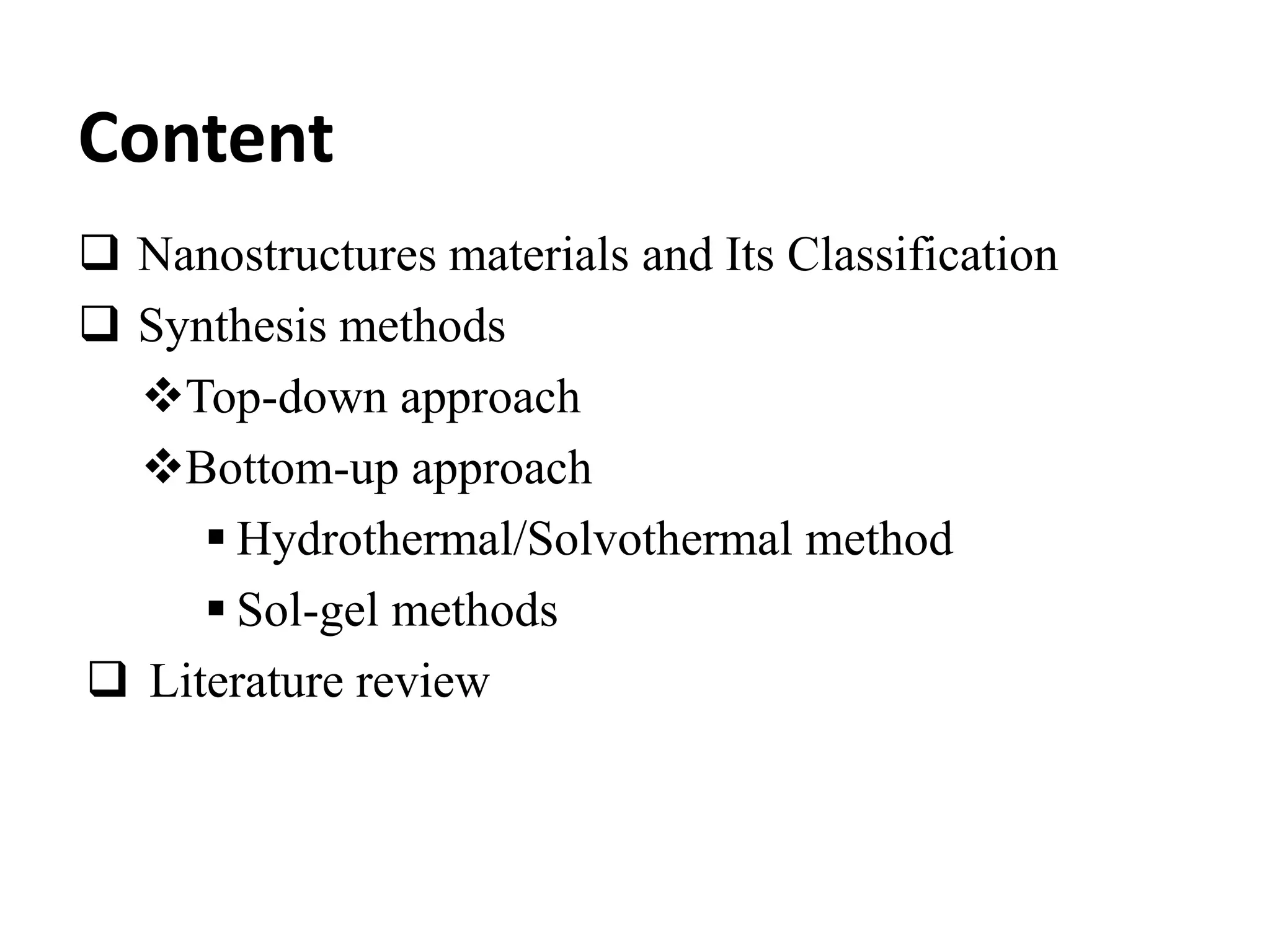

![Literature review based on these techniques

Compound Morphology Raw Materials Conditions Techniques Ref

.

Co3O4 a) Nanobelts

b) Nanoparticles

Co5(OH)6(CO3)2.nH2O, NH3.H2O,

and deionized water

a) 12h at 180℃

b) 12h at 140℃

Hydrothermal/solvot

hermal method

[1]

ZnO a) 3D flower like

b) 2D nanosheets

c) 1D nanorods

d) 0D spherical shape

Zn(NO3)2.6H2O (0.5M) and NaOH

(5M), and distilled water

a) 2h at [125-150]℃

b) 2h at [100-125]℃

c) 5h at 120℃

d) 2h at 150℃

Hydrothermal

method

[2]

ZnS Nanoparticles ZnSO4.5H2O, Na2S.7H2O, and

deionized water

12h at 220℃ Hydrothermal

method

[3]

TiO2 Nanowires TiO2 powder (Degussa P25), NaOH

(15M)

72h at 170℃ Hydrothermal

method

[4]

ZnO Nanoparticles Zn(CH3CO2)2 (Zinc acetate), citric

acid

2days (sol.)

3days dried (for powder

formation)

Sol-gel method [5]

ZnO Nanorods Zinc Acetate Dihydrate

(Zn(CH3COO)2.2H2O), NaOH,

Ethanol (CH2COOH) and distilled

water.

Few hour Sol-gel method [6]](https://image.slidesharecdn.com/1ppt-220418110823/75/Synthesis-and-Classification-of-Nanostructured-materials-pptx-9-2048.jpg)