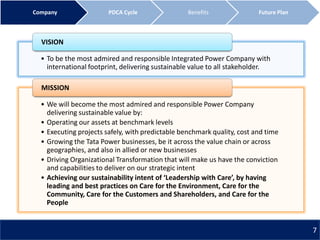

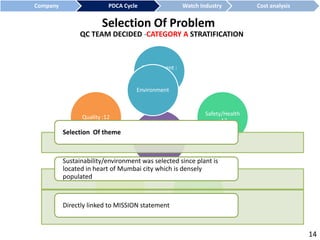

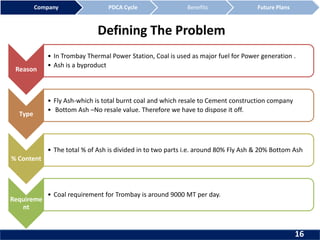

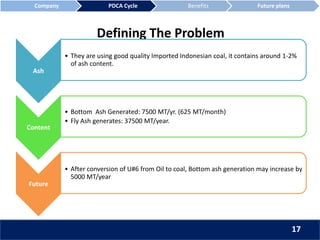

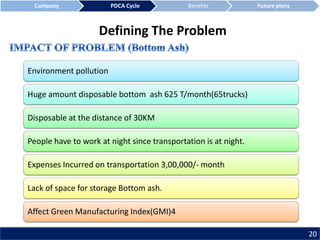

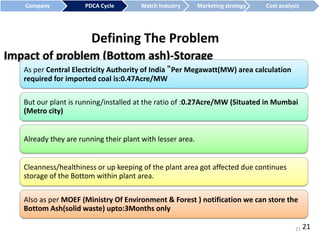

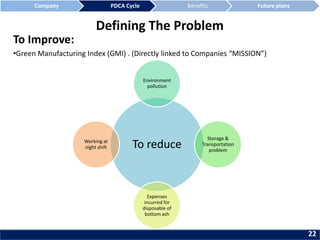

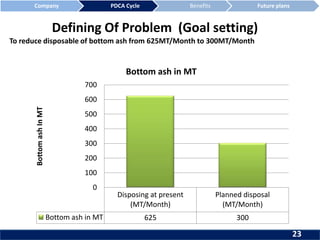

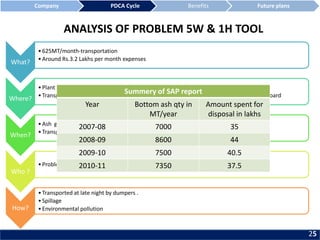

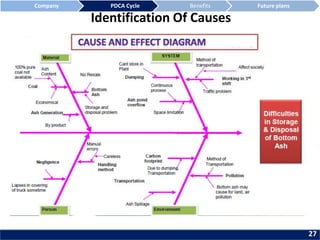

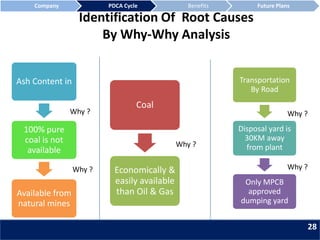

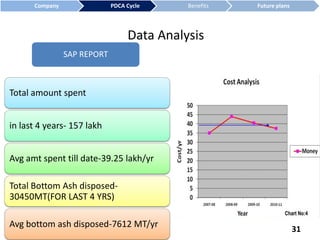

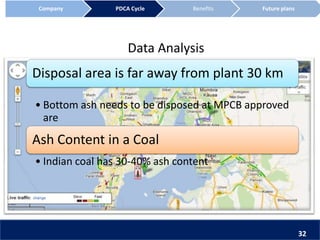

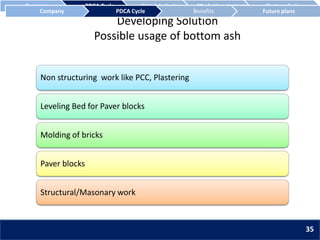

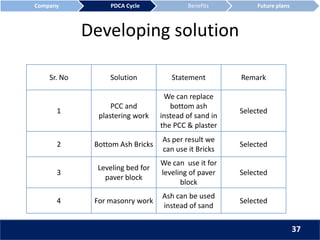

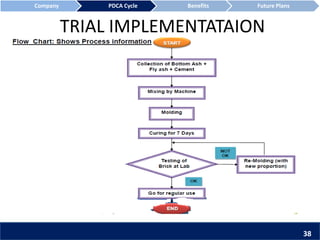

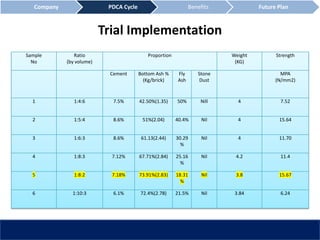

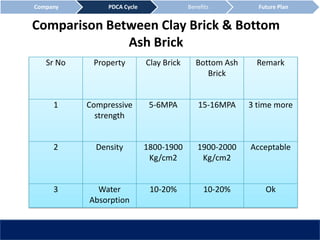

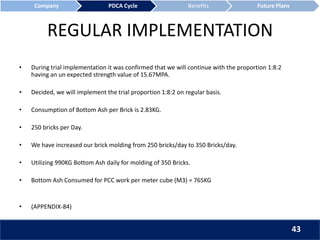

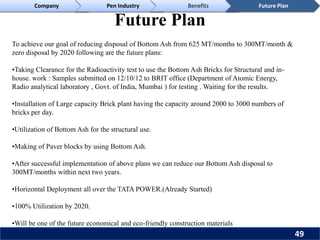

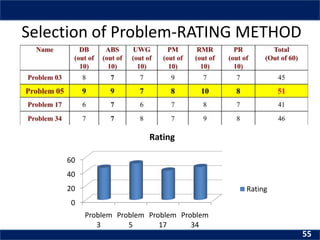

This document provides a case study on Tata Power's efforts to increase the sustainable use of bottom ash, a byproduct of coal combustion. It details the quality circle team's application of the PDCA (Plan-Do-Check-Act) process to address the problem of disposing 625 metric tons of bottom ash per month. Through root cause analysis, trials, and regular implementation, the team developed a solution to incorporate bottom ash into bricks, reducing monthly disposal to 300 metric tons. Tangible benefits included savings of over Rs. 4 lakhs in transportation costs and Rs. 18 lakhs in natural sand costs. Future plans aim to further reduce disposal and deploy the approach across Tata Power.