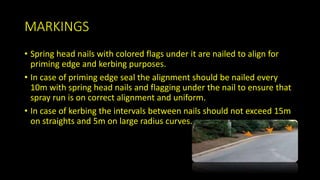

This document discusses surveying basics applied to road projects. It explains that control points are used to locate other points and their accuracy directly impacts the quality of the finished pavement. It also discusses reestablishing control points, clearing lines by offsetting from string lines, leveling which road bases depend on, marking points for priming edge and kerbing with nails and flags, and establishing lane markings before paving so the joins coincide with the lines.