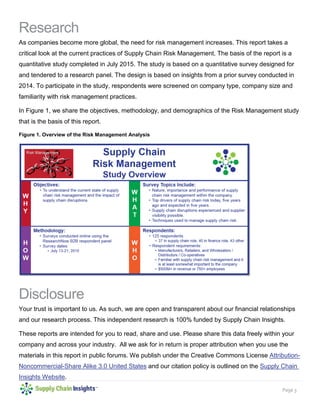

This document discusses the importance of risk management for companies with global supply chains. It summarizes the results of a quantitative study on current risk management practices. Some key findings are:

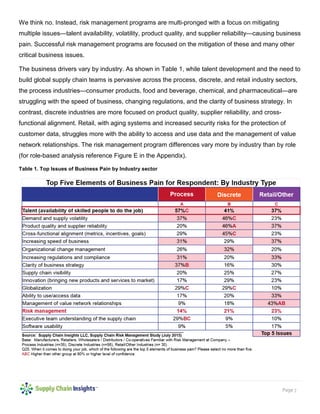

1) Risk management is seen as important for preventing disruptions but ranks lower than other business issues in terms of pain.

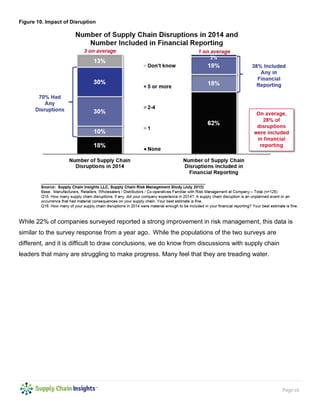

2) Supply chain disruptions, especially those involving ports, can have major impacts that linger for years.

3) Advanced risk management programs are led by top executives and focus on prevention, early detection of issues, and contingency planning.

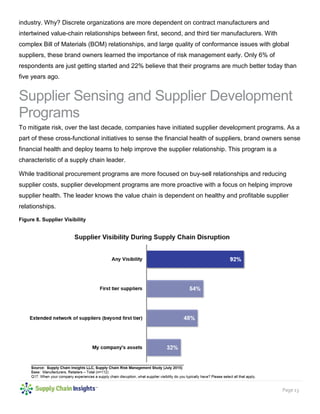

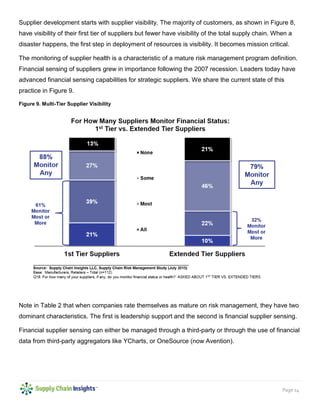

4) Monitoring supplier financial health and developing suppliers are seen as important aspects of risk management by more mature programs.