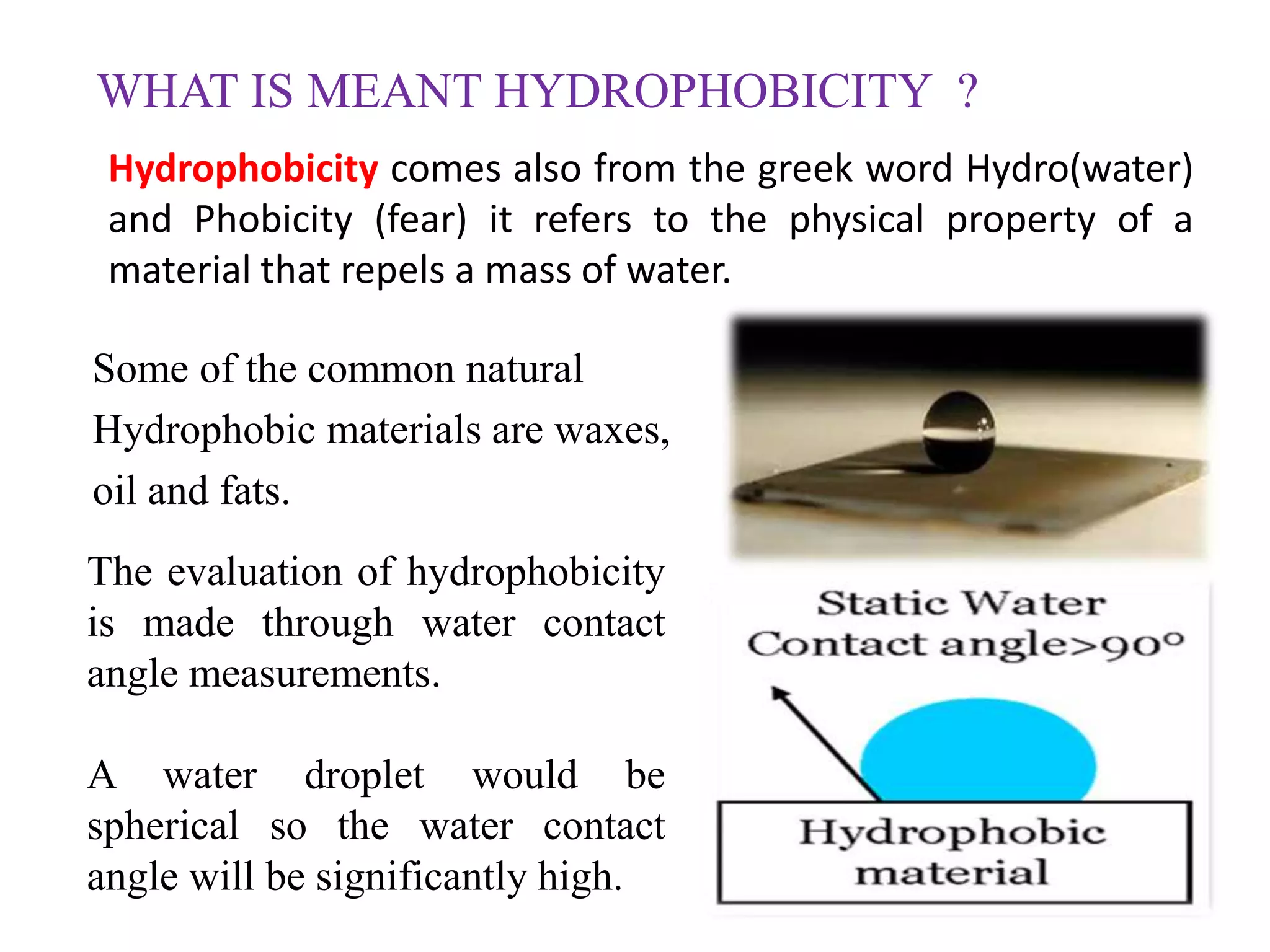

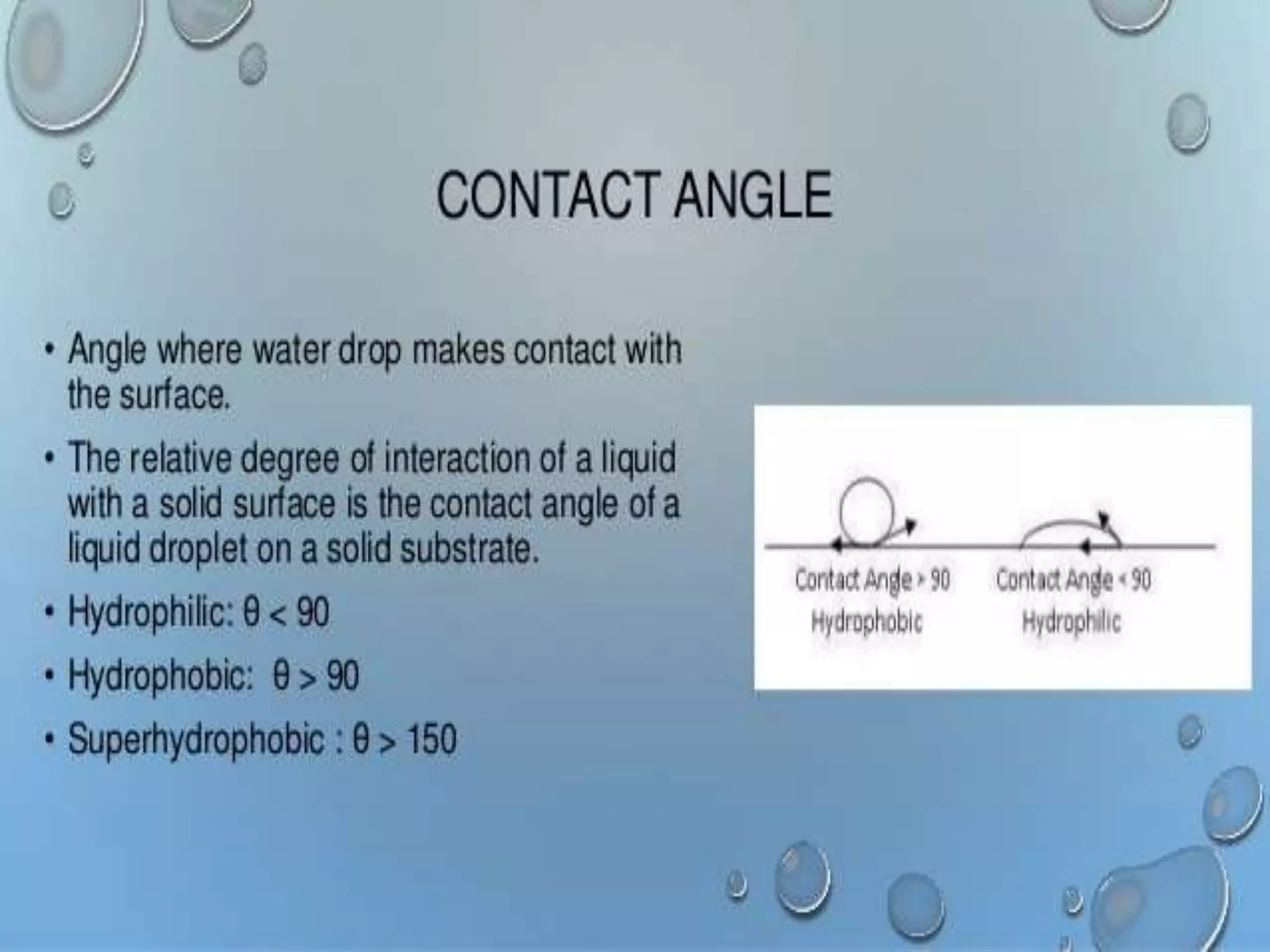

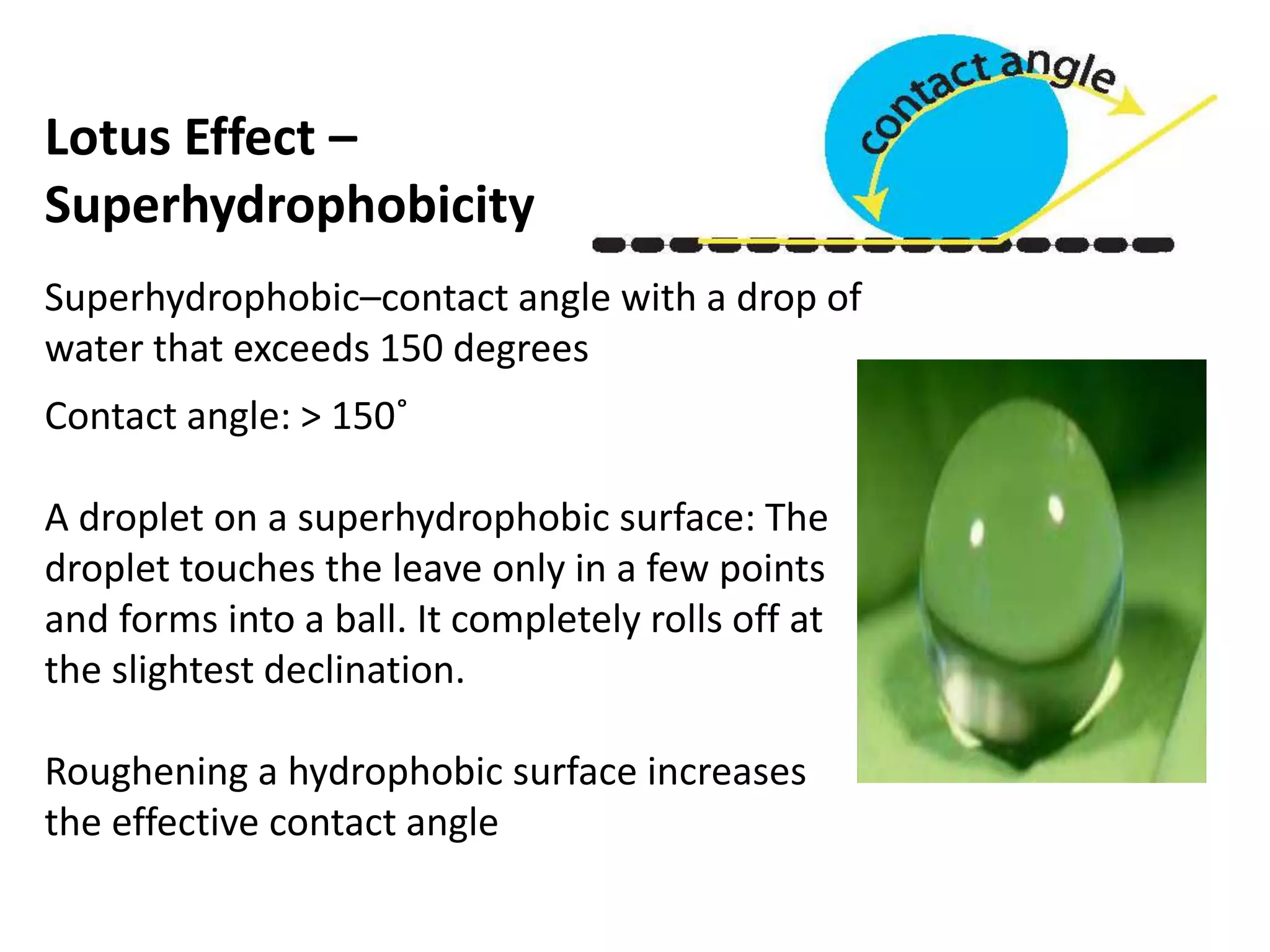

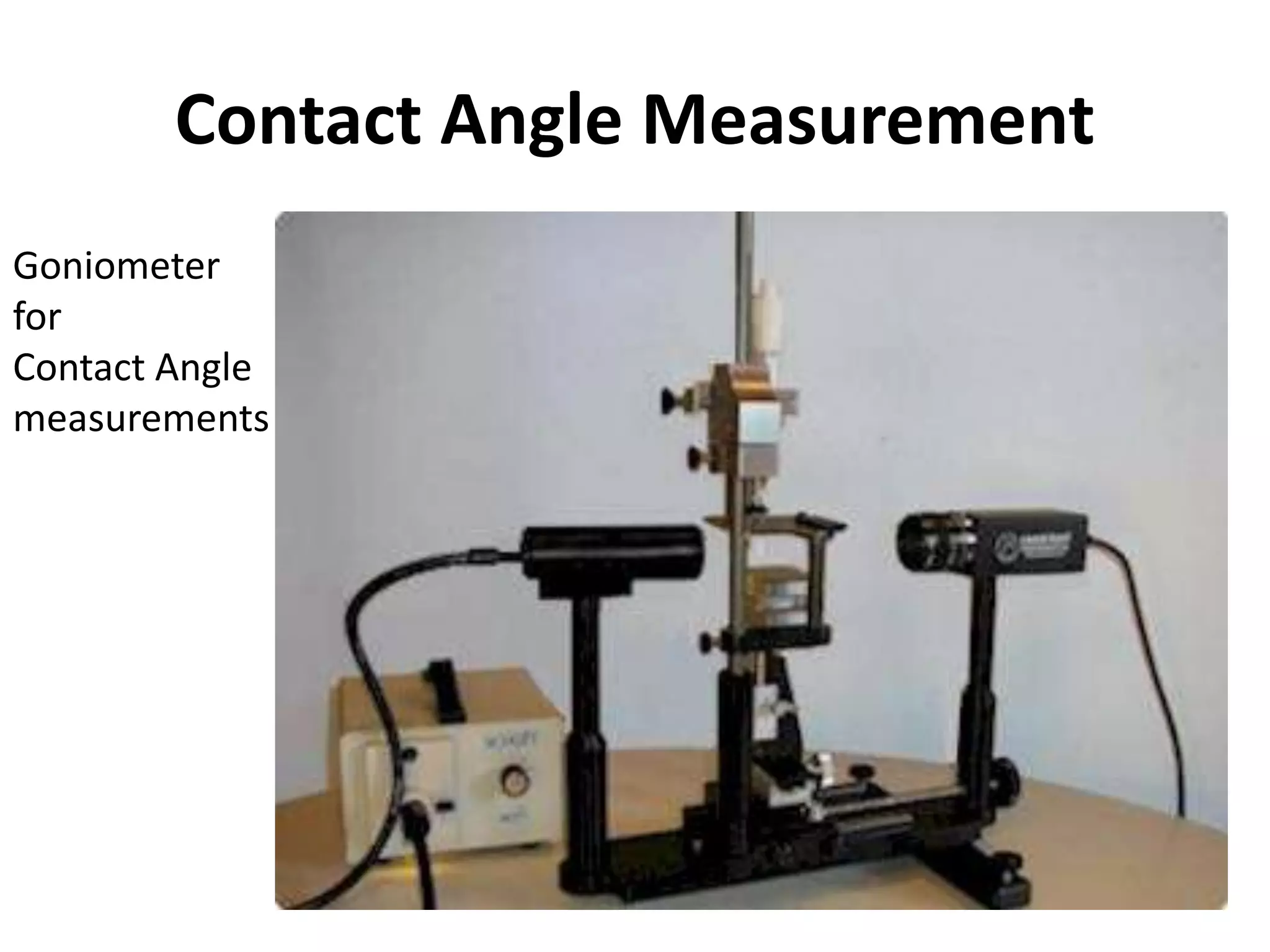

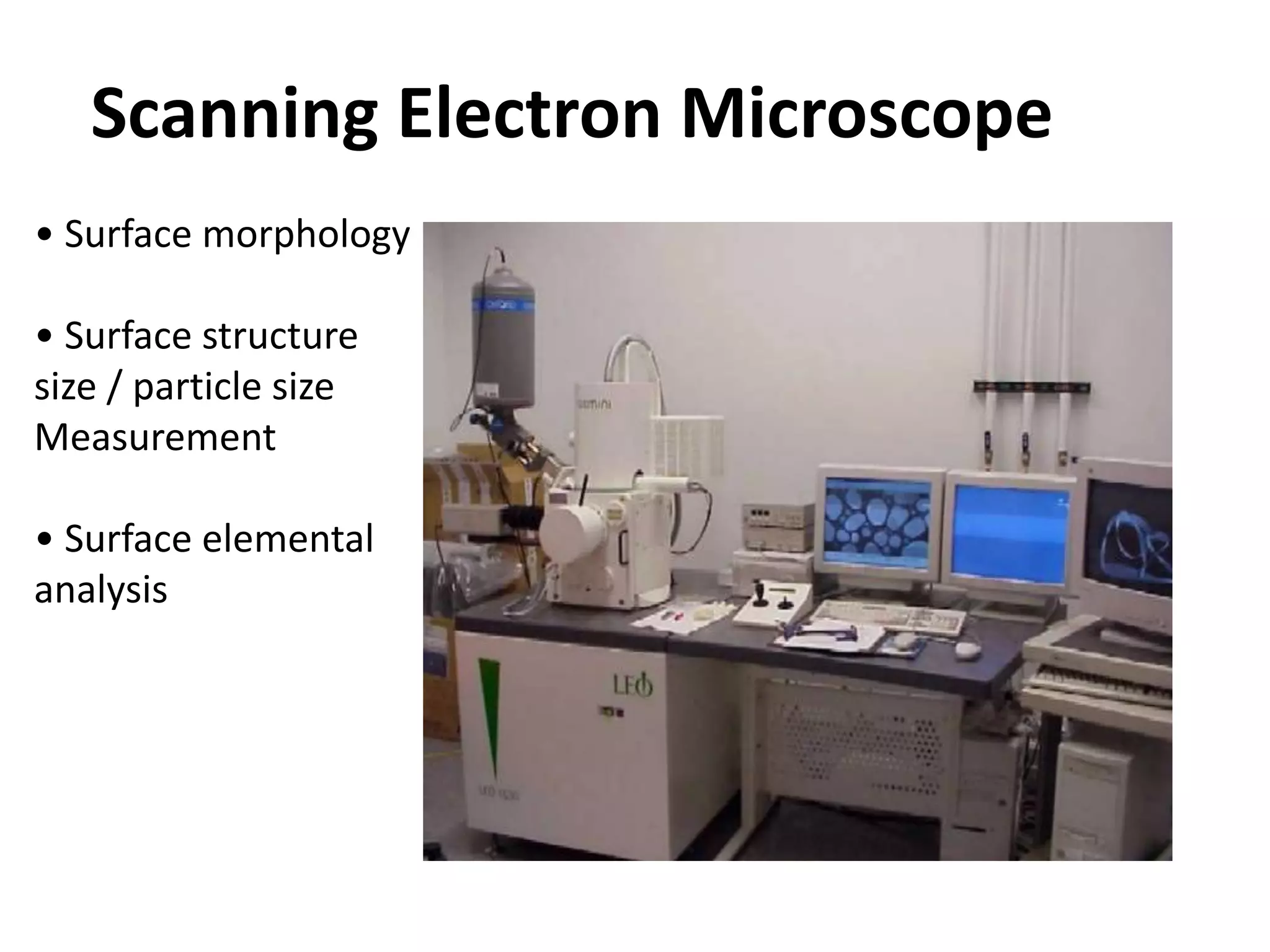

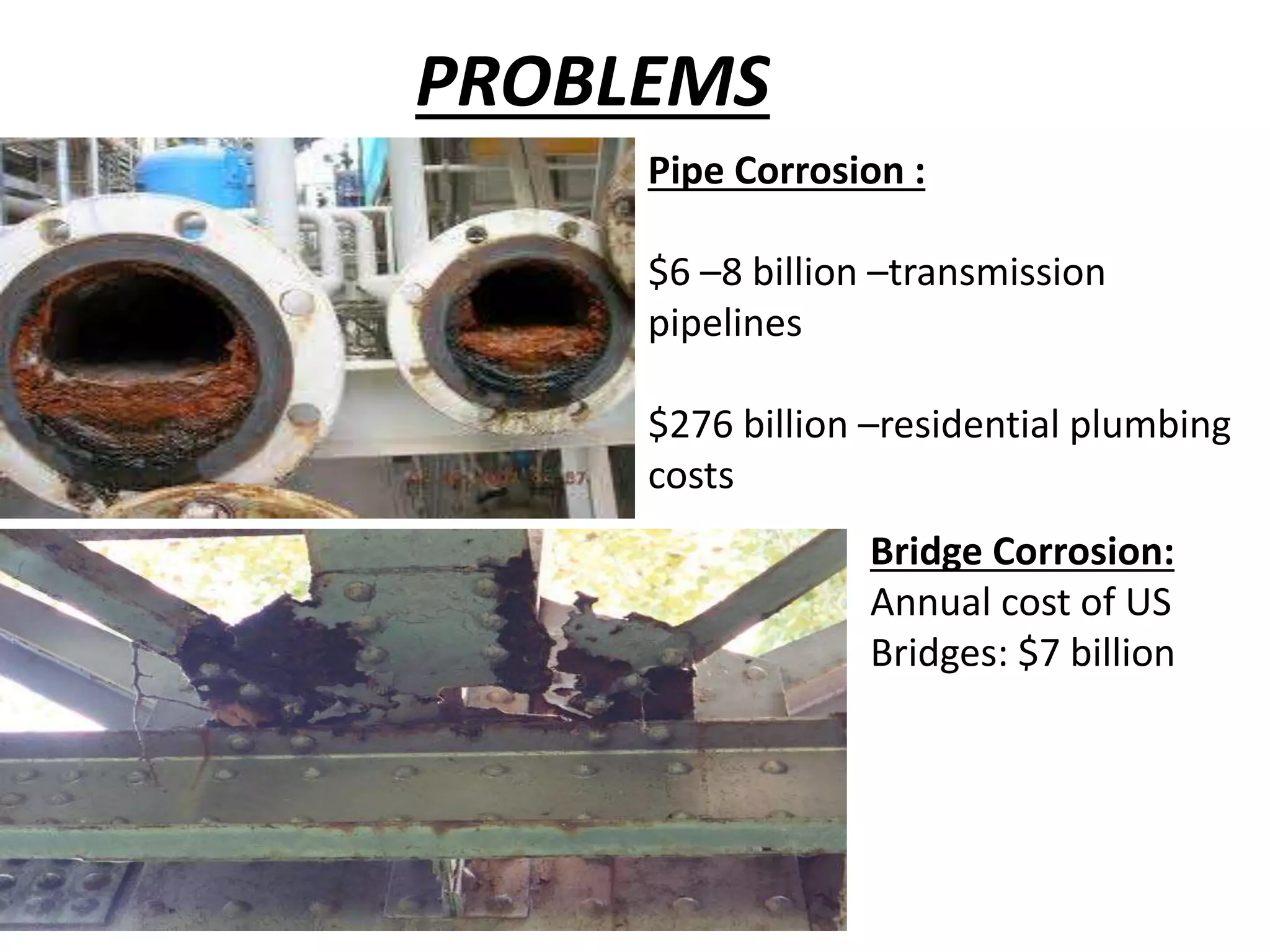

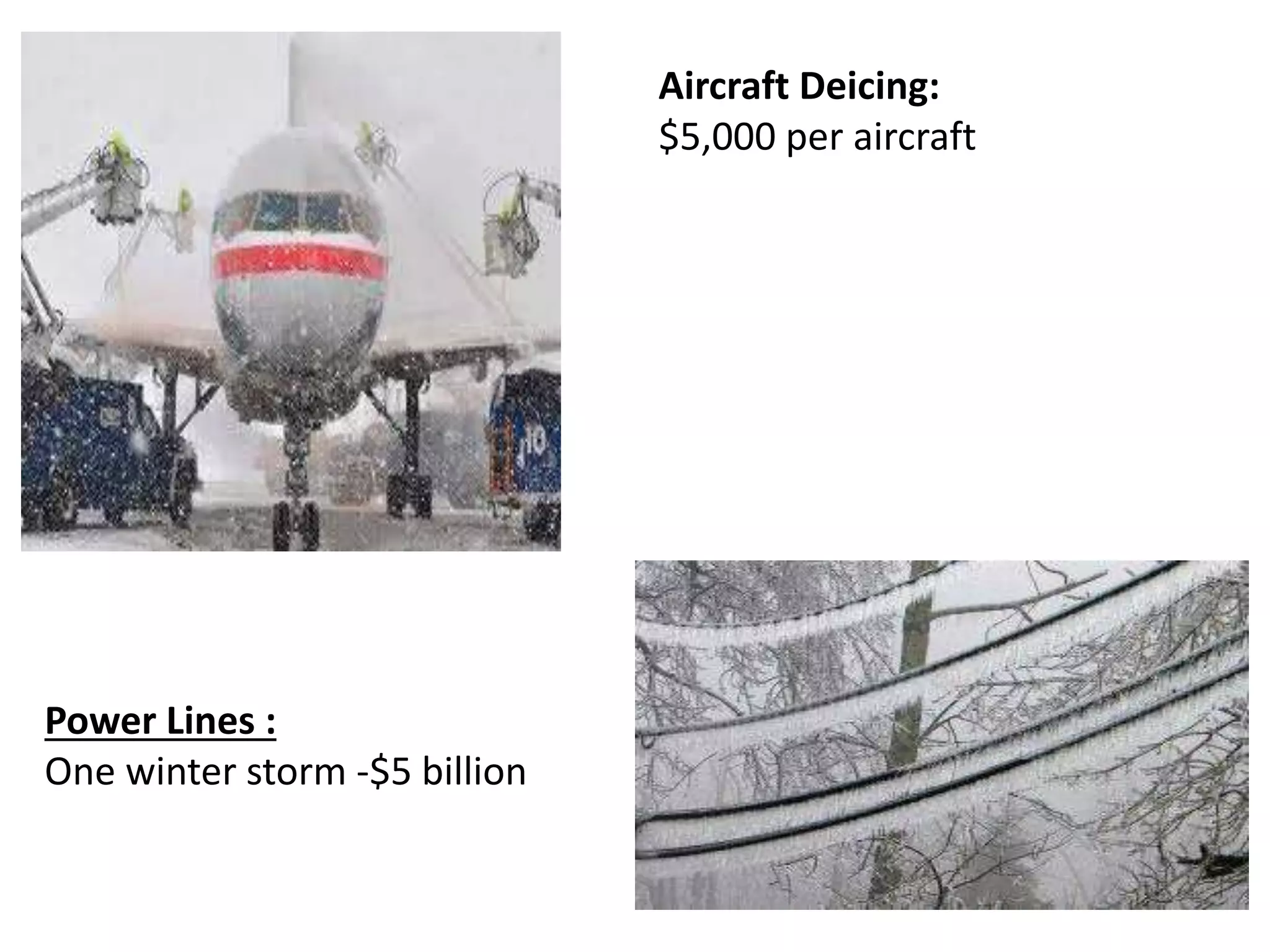

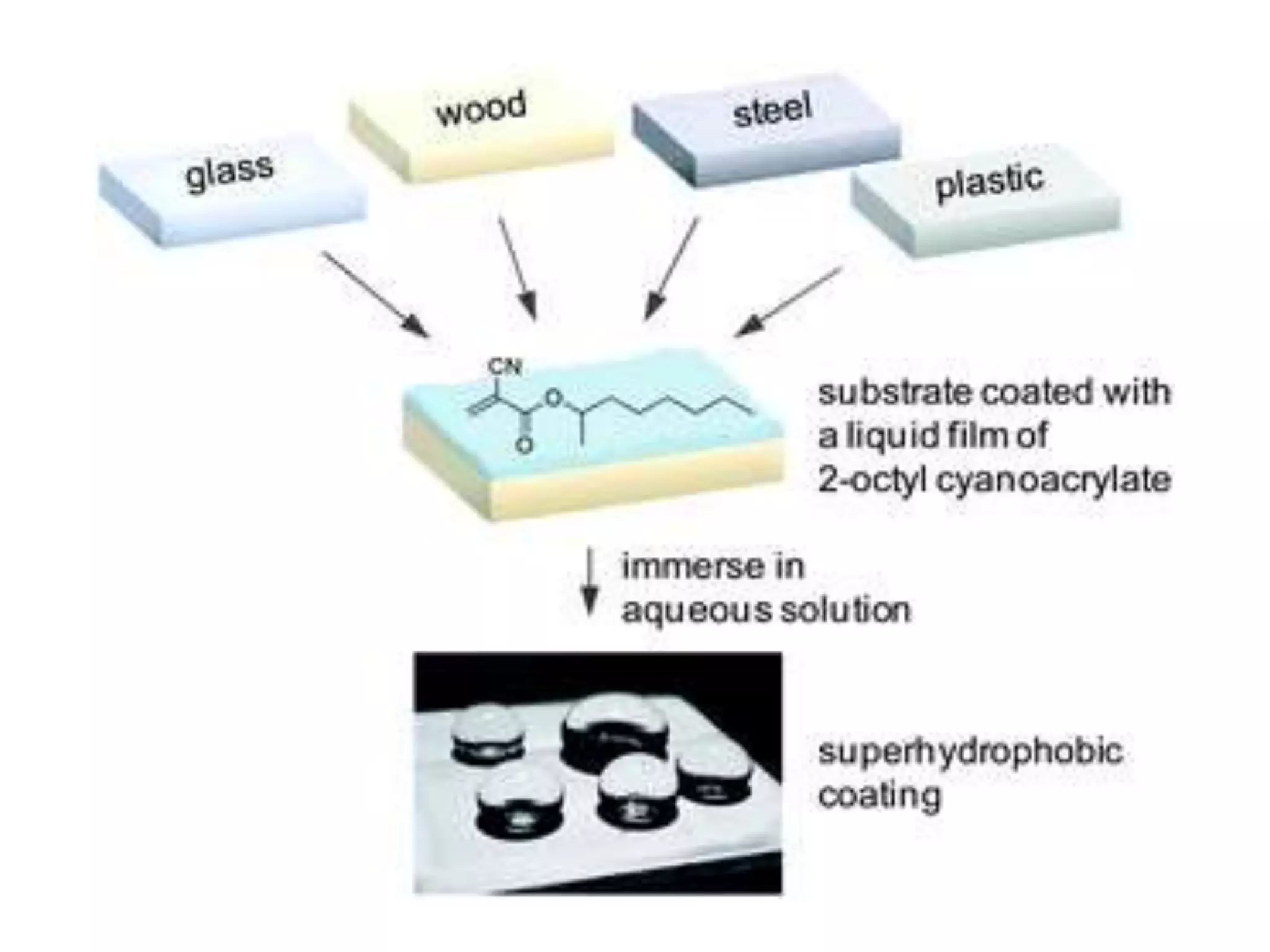

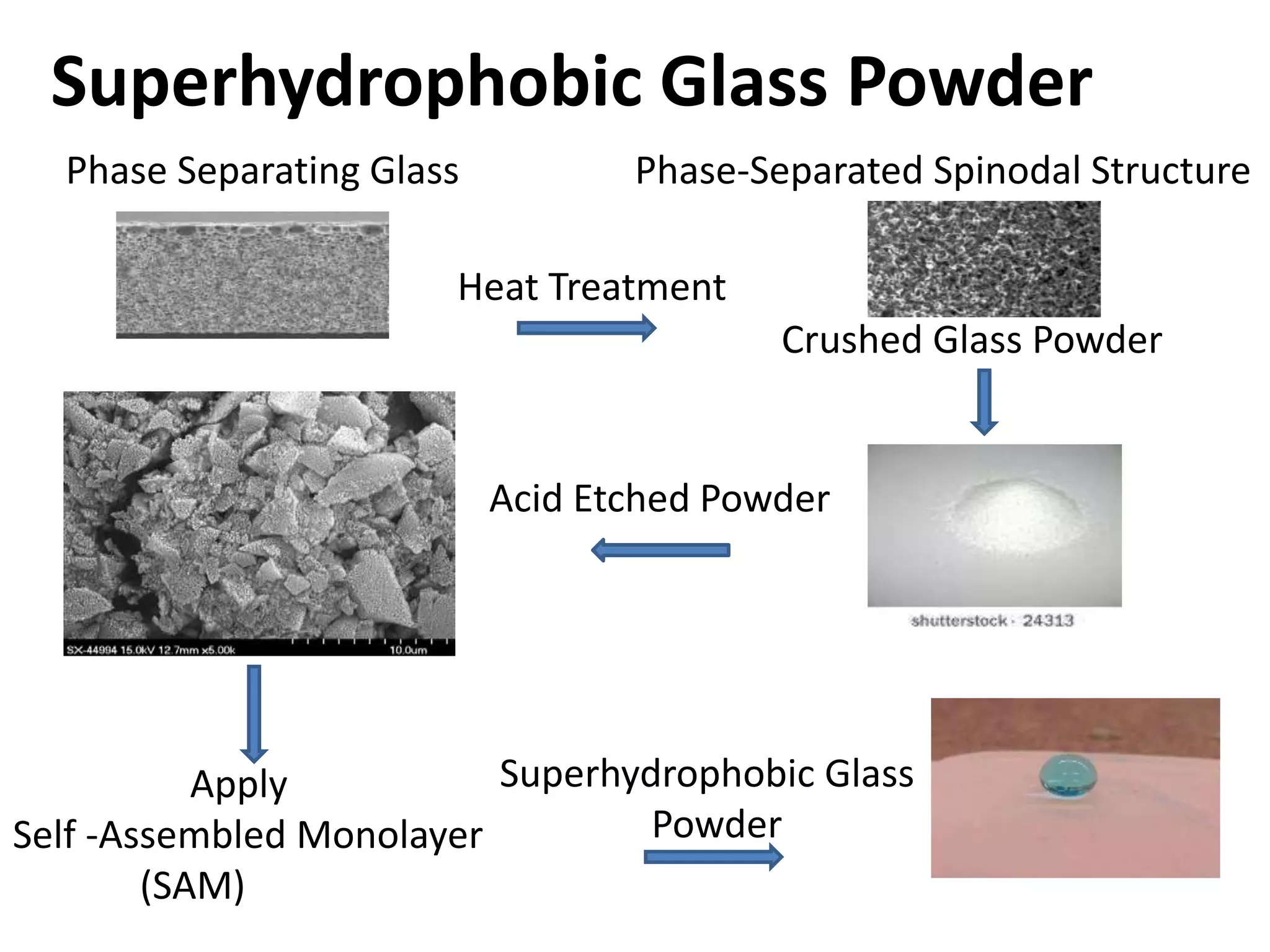

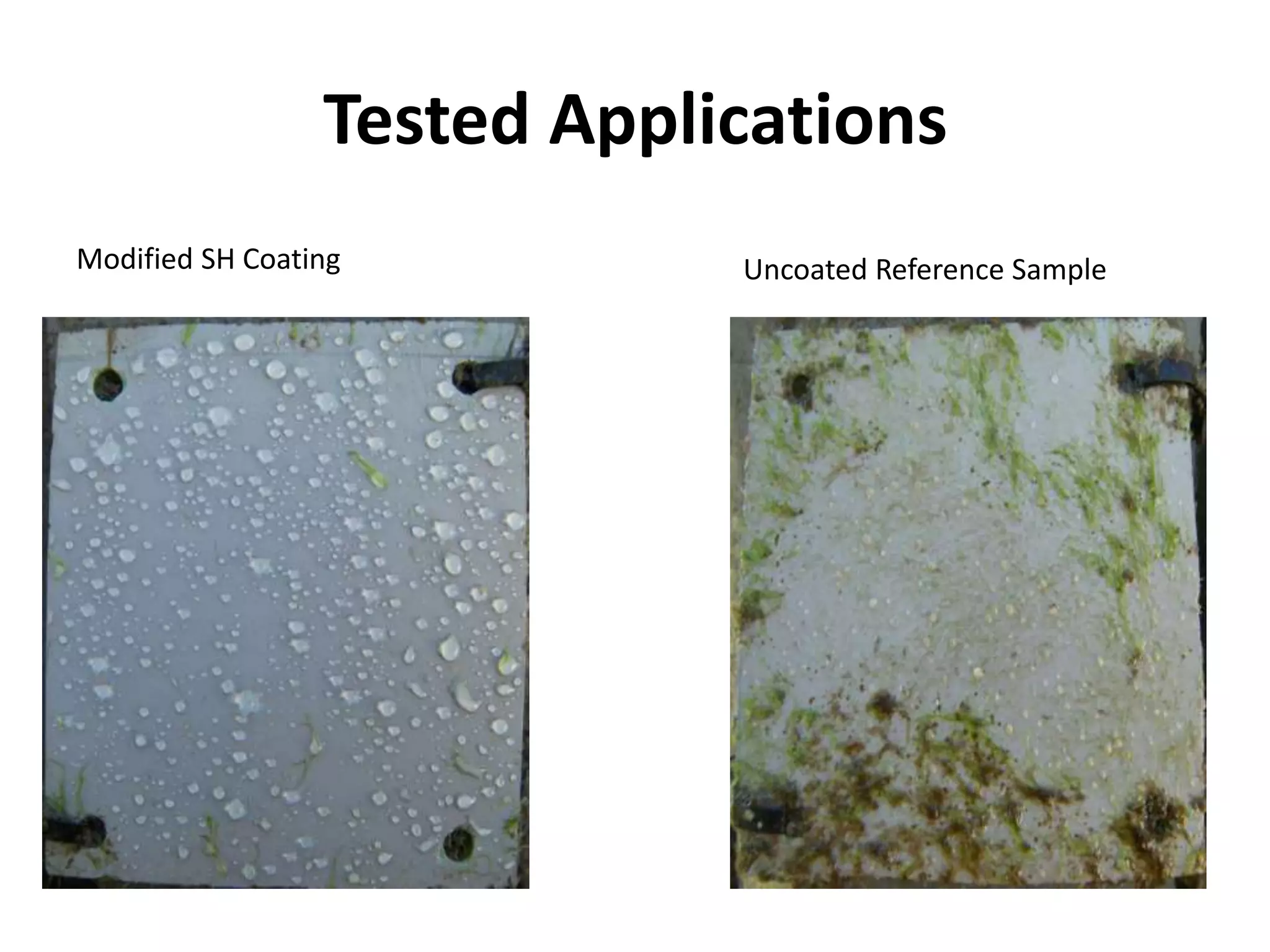

Superhydrophobic materials repel water due to their surface morphology and chemistry. The seminar discussed the properties of superhydrophobicity where the water contact angle exceeds 150 degrees. Examples of applications included anti-corrosion coatings for infrastructure like bridges and pipelines, aircraft deicing, self-cleaning surfaces, and anti-fouling coatings. The talk covered measuring contact angles, examples of superhydrophobic materials like manganese oxide and silica coatings, and potential products like coatings for cables and glass.