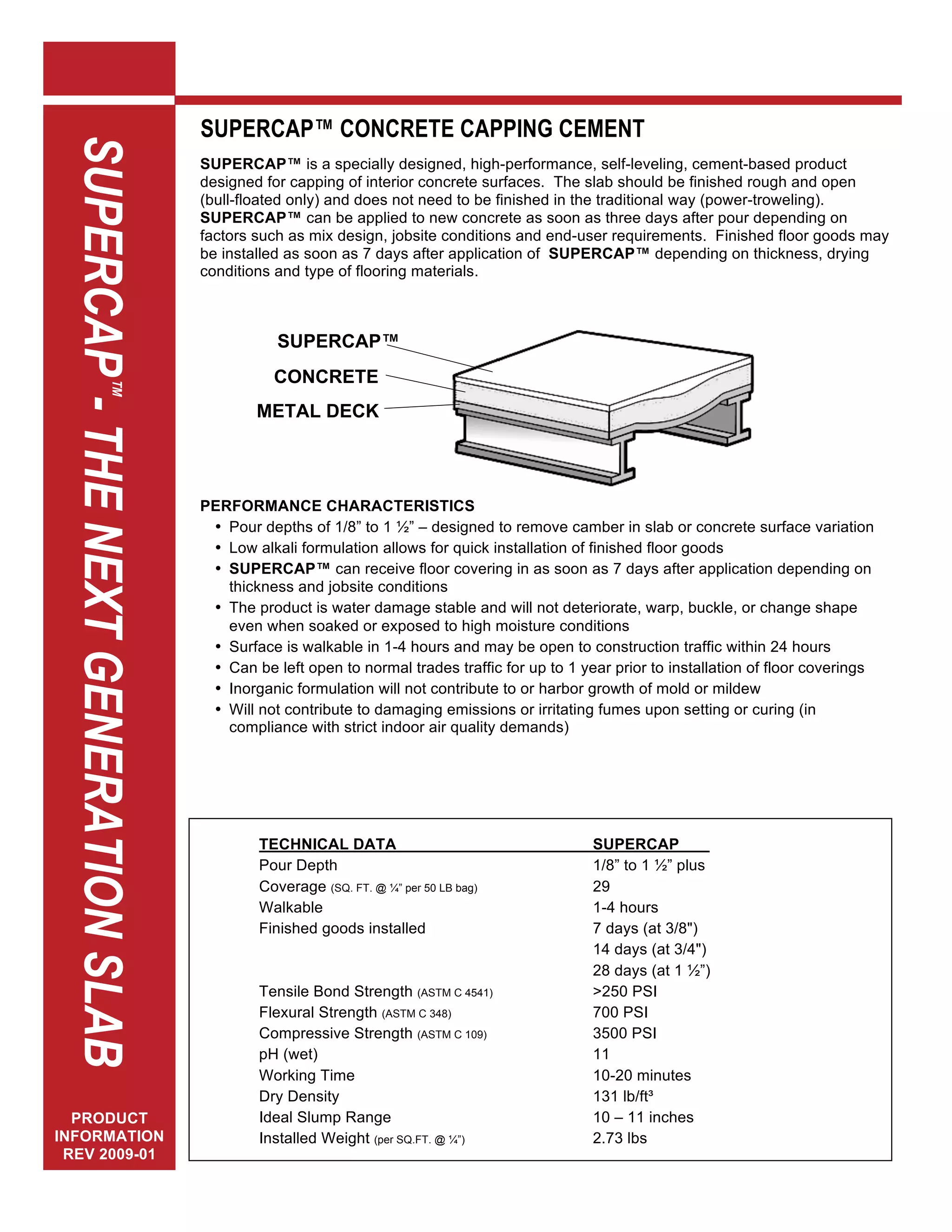

SUPERCAP is a self-leveling cement product used to cap interior concrete surfaces from 1/8 to 1 1/2 inches thick. It can accept flooring installation in as little as 7 days and provides a smooth, level surface without the need for traditional finishing techniques like power troweling. SUPERCAP is moisture and damage resistant, walkable within hours, and can withstand construction traffic for up to a year before flooring installation. It applies over properly prepared concrete at least 3 days old with a moisture content of 95% or less.