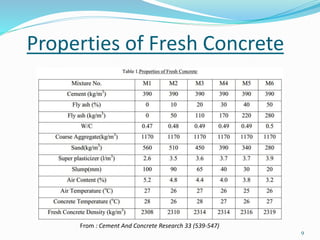

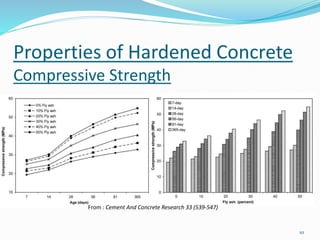

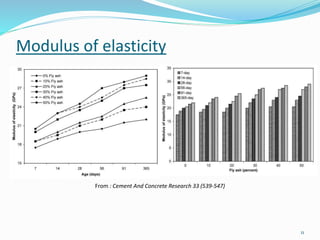

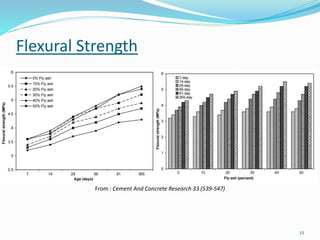

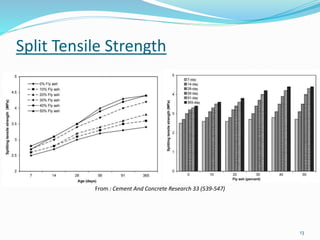

The document discusses high volume fly ash concrete (HVFAC), which uses a 50-60% replacement of cement with fly ash. Fly ash is a byproduct of coal combustion that exhibits pozzolanic behavior. HVFAC provides benefits like lower heat production, improved sulfate and sea water resistance, and higher strength properties compared to normal concrete. The document outlines the production and availability of fly ash, factors affecting fly ash concrete performance like fineness and calcium content, applications of HVFAC in dam and pavement construction, and longer curing requirements.