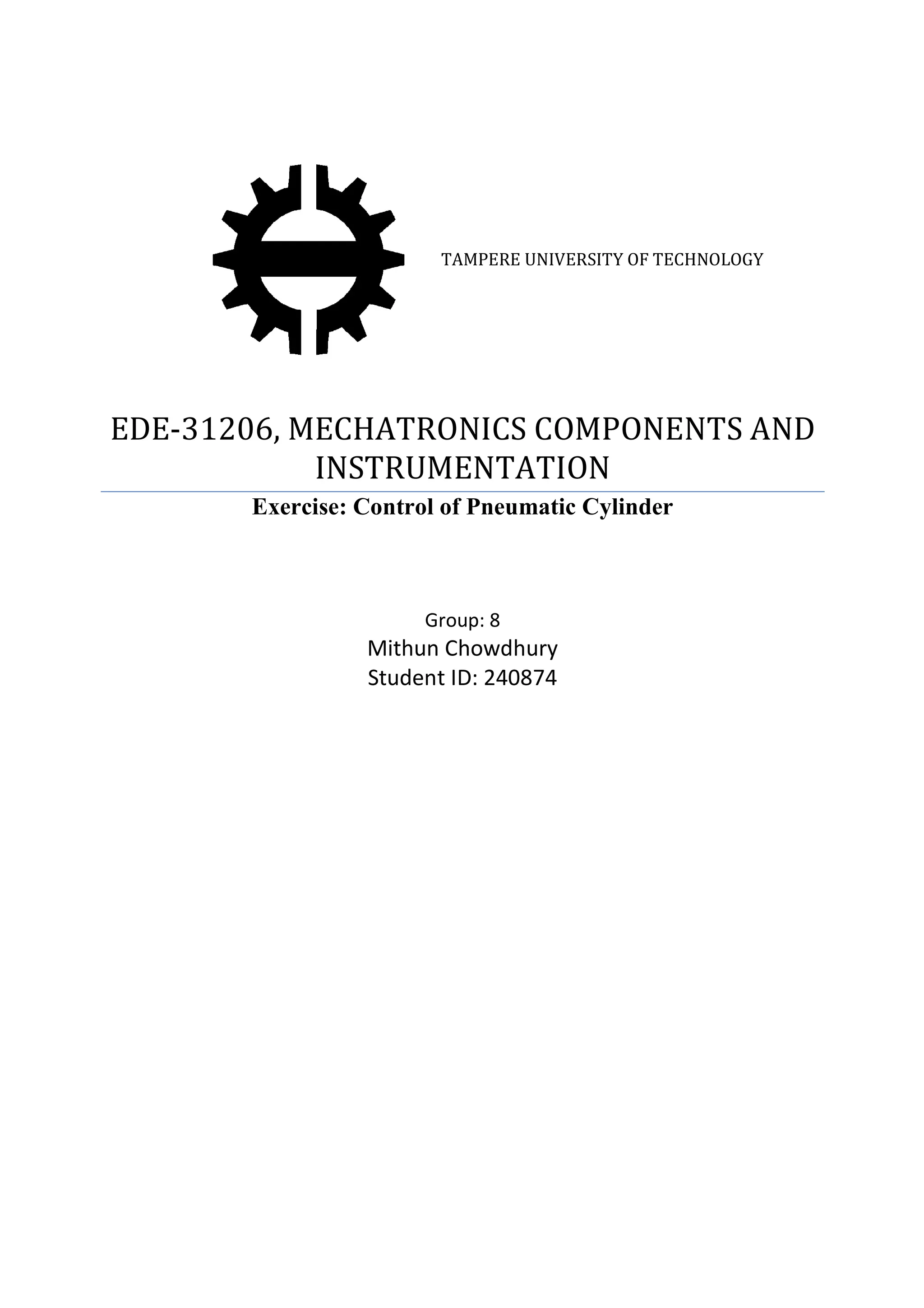

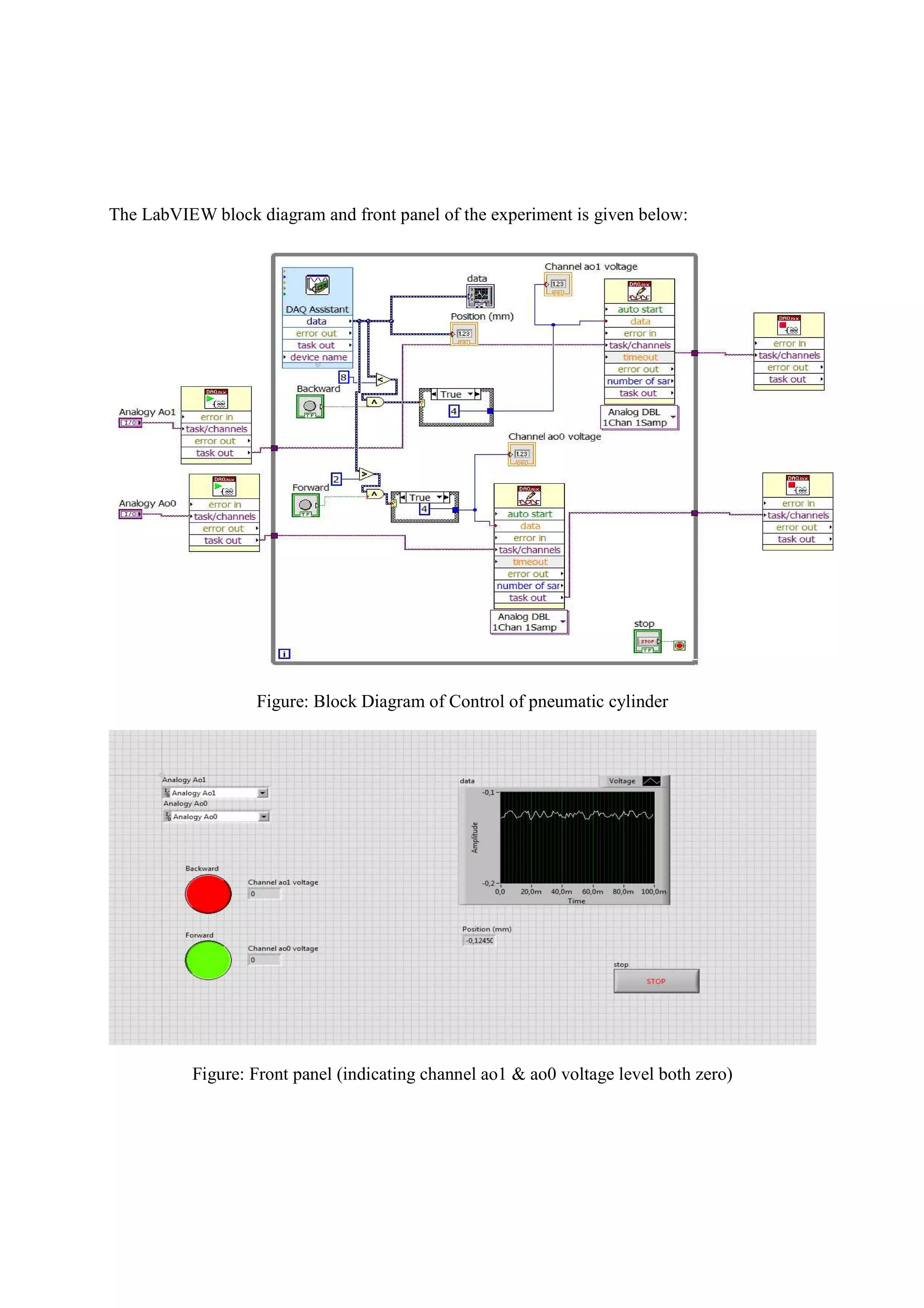

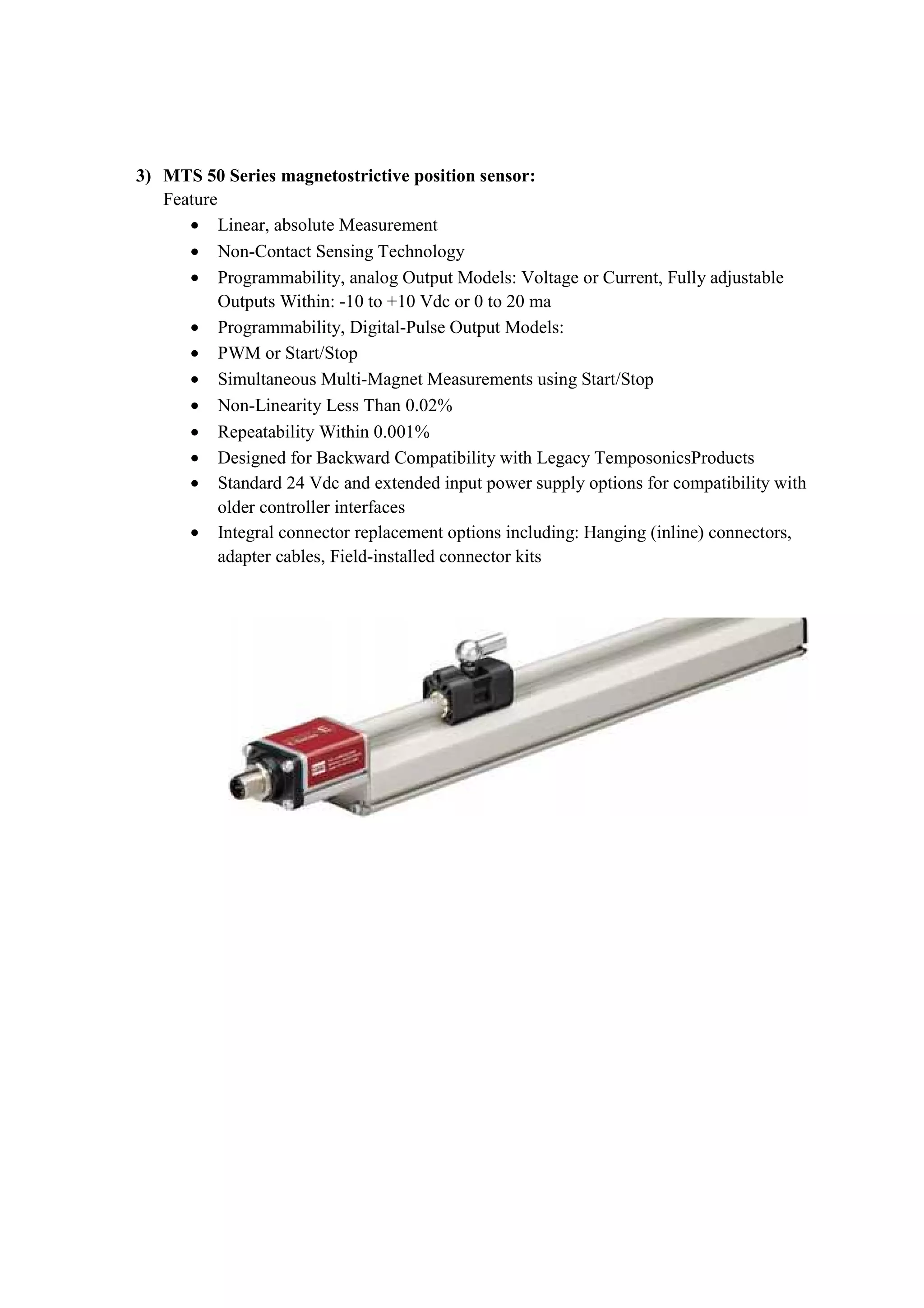

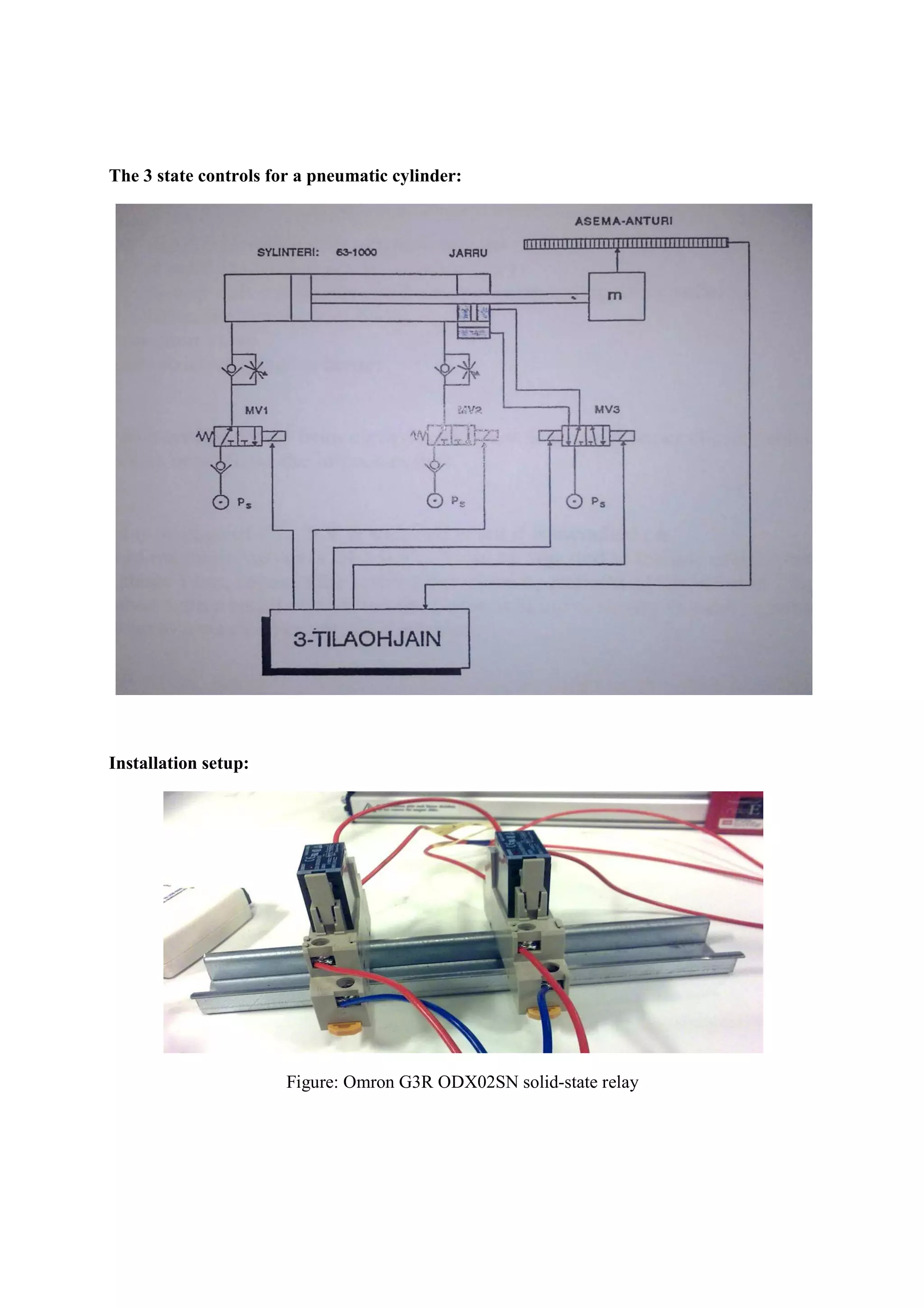

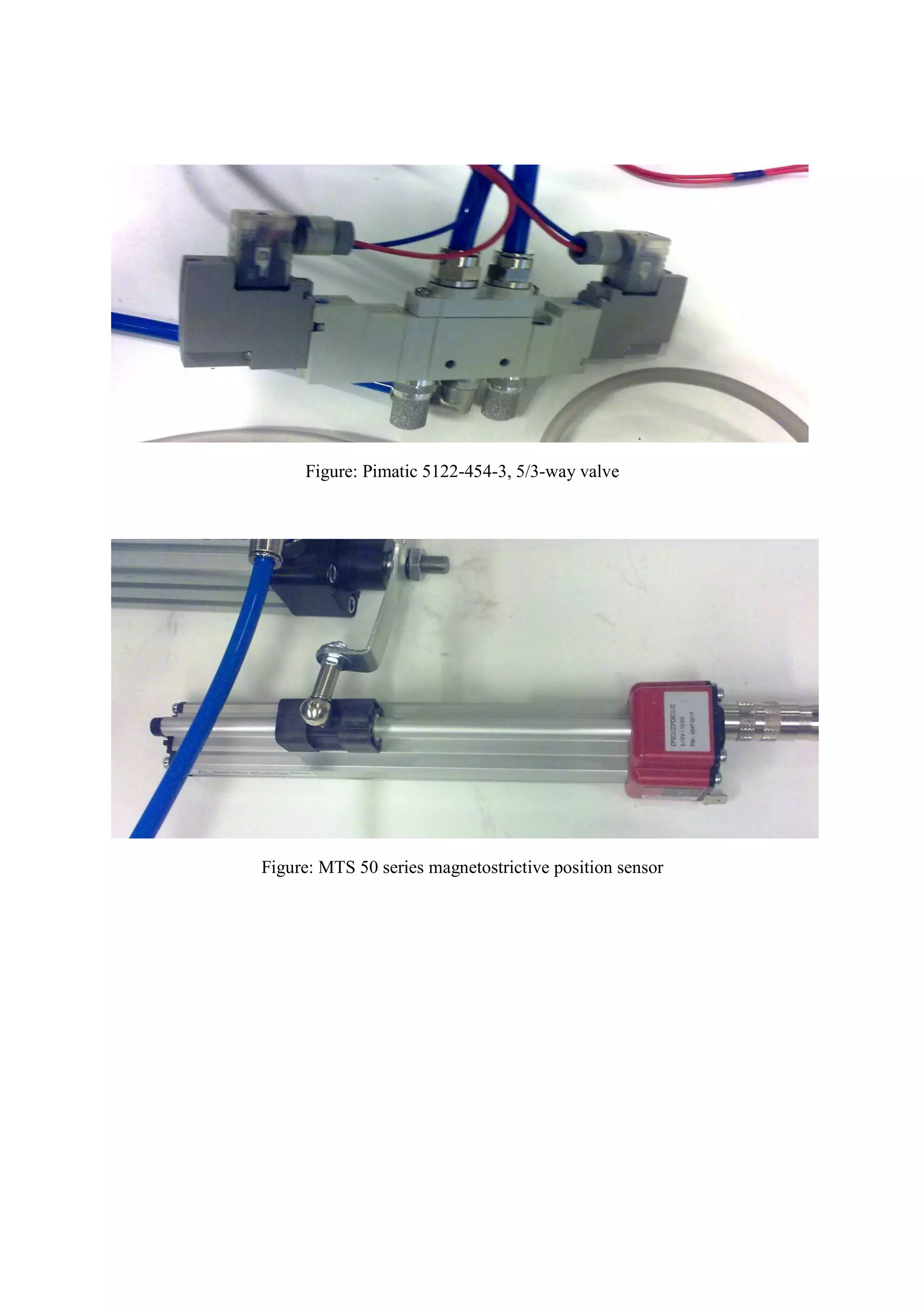

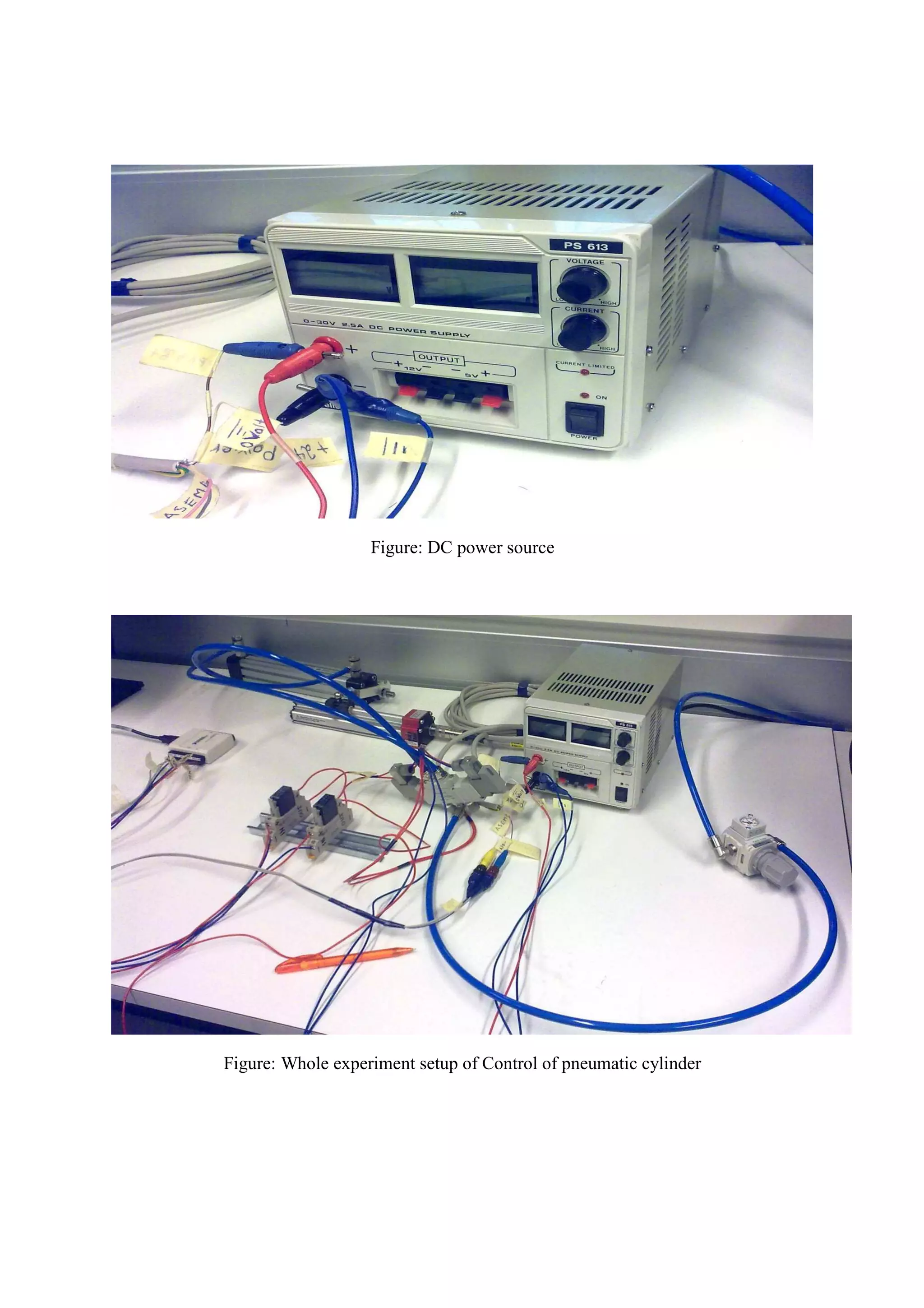

This document describes an experiment on controlling a pneumatic cylinder using LabVIEW. The experiment uses a NI USB-6009 data acquisition card to control an Omron G3R solid state relay that regulates air flow to a 5/3-way valve controlling a pneumatic cylinder. A MTS 50 series magnetostrictive sensor measures the cylinder position. The LabVIEW block diagram and front panel show the analog output channels controlling the relay to move the cylinder between two positions. Diagrams show the components and overall experiment setup.