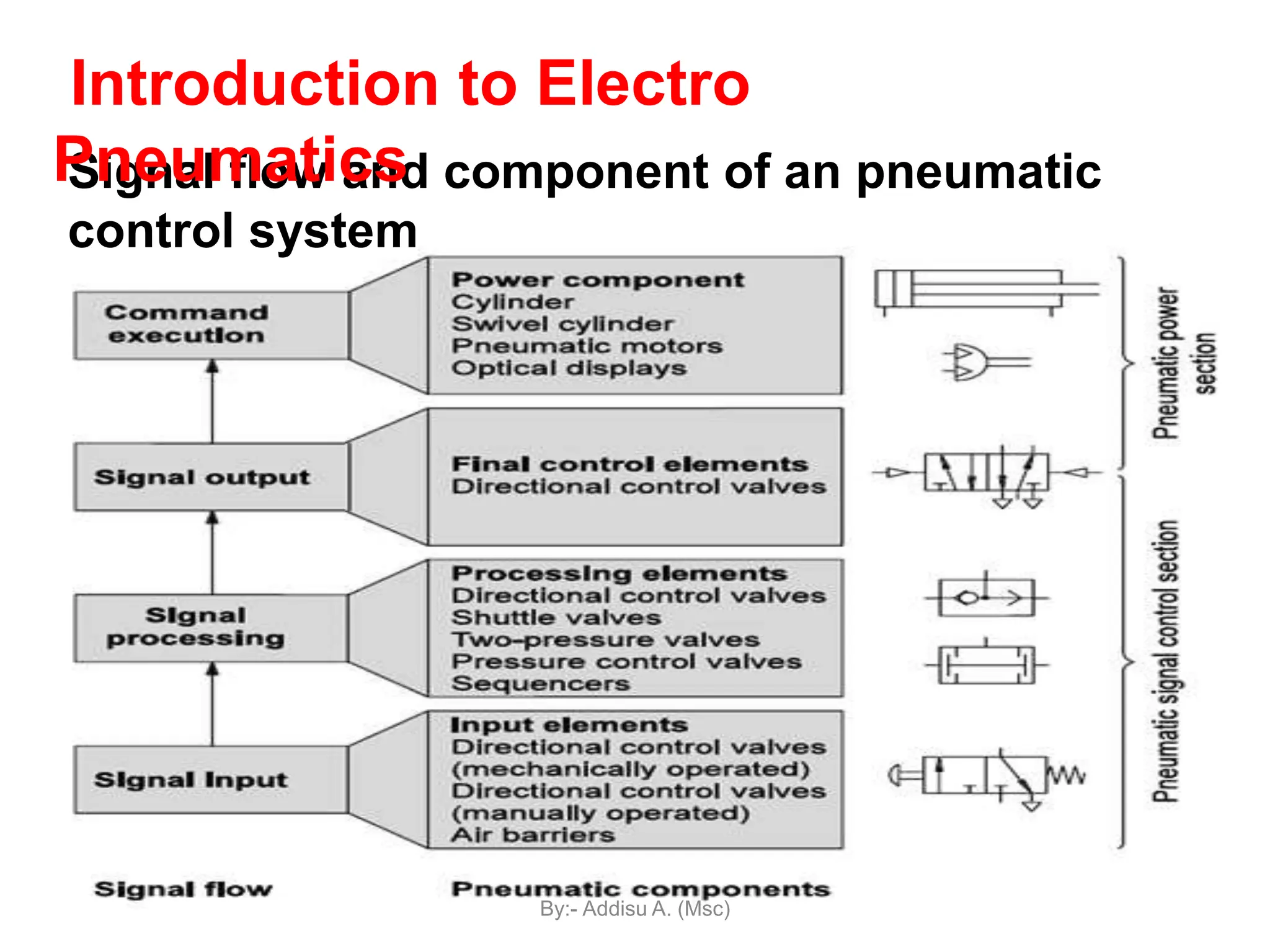

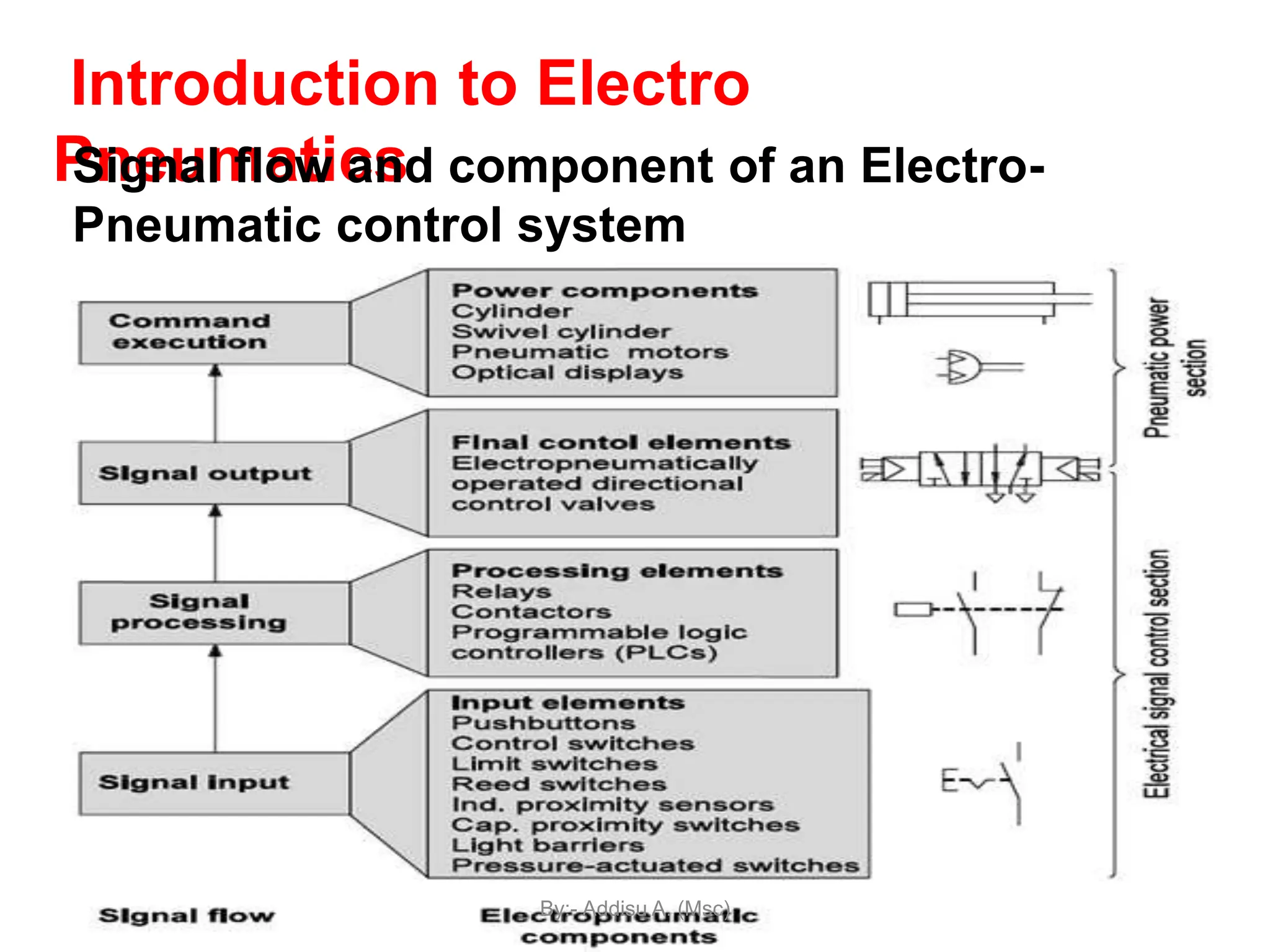

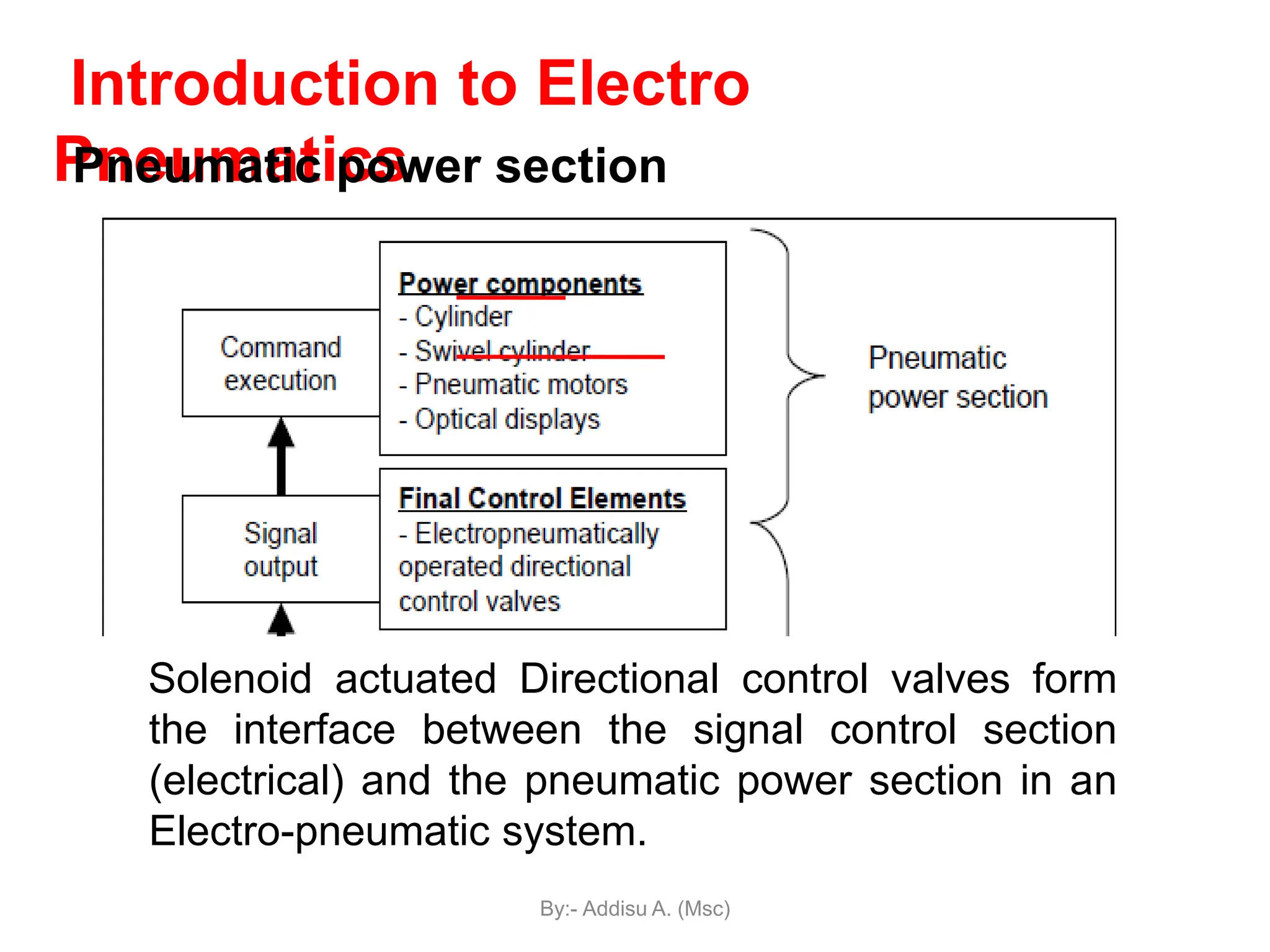

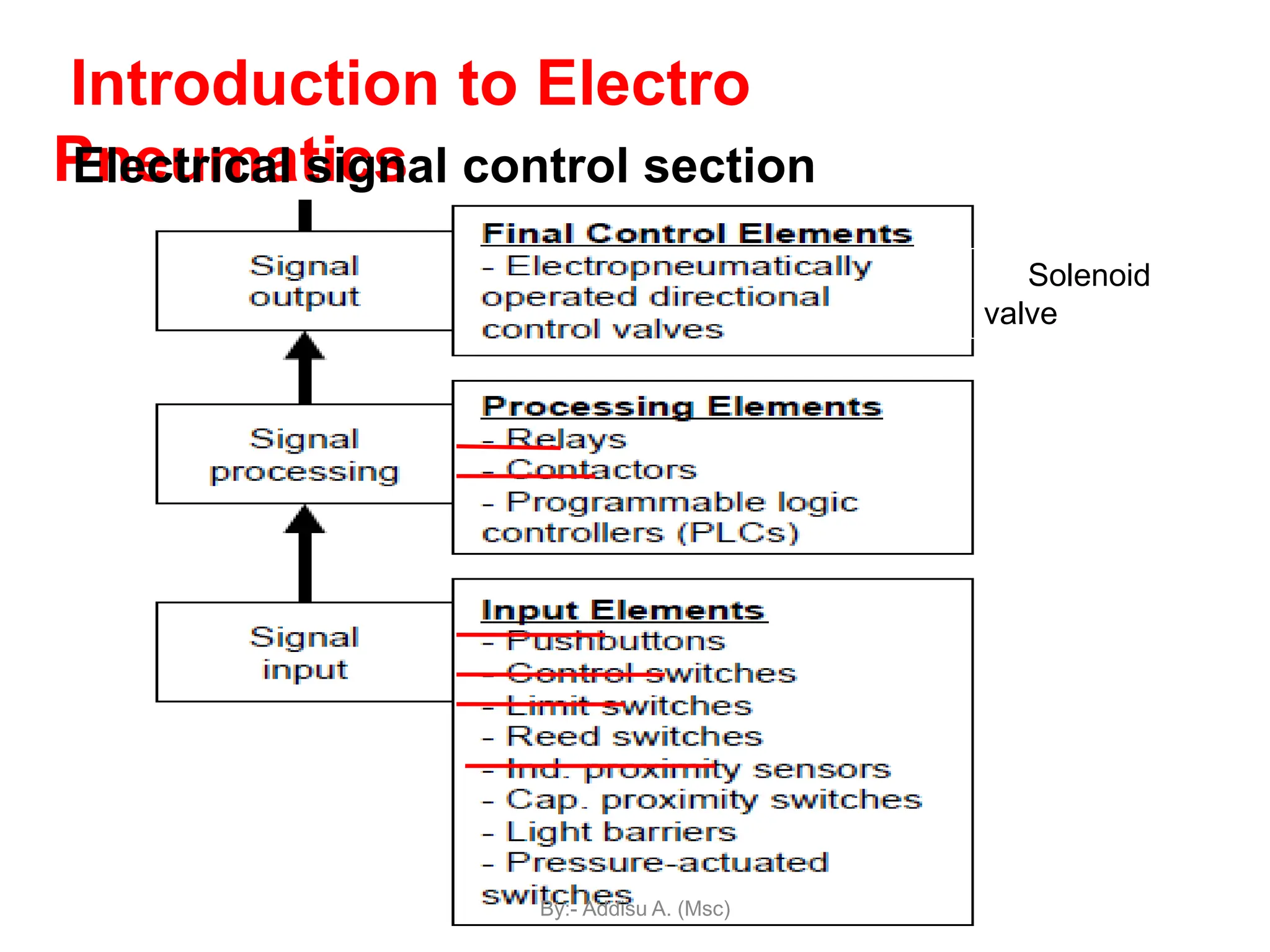

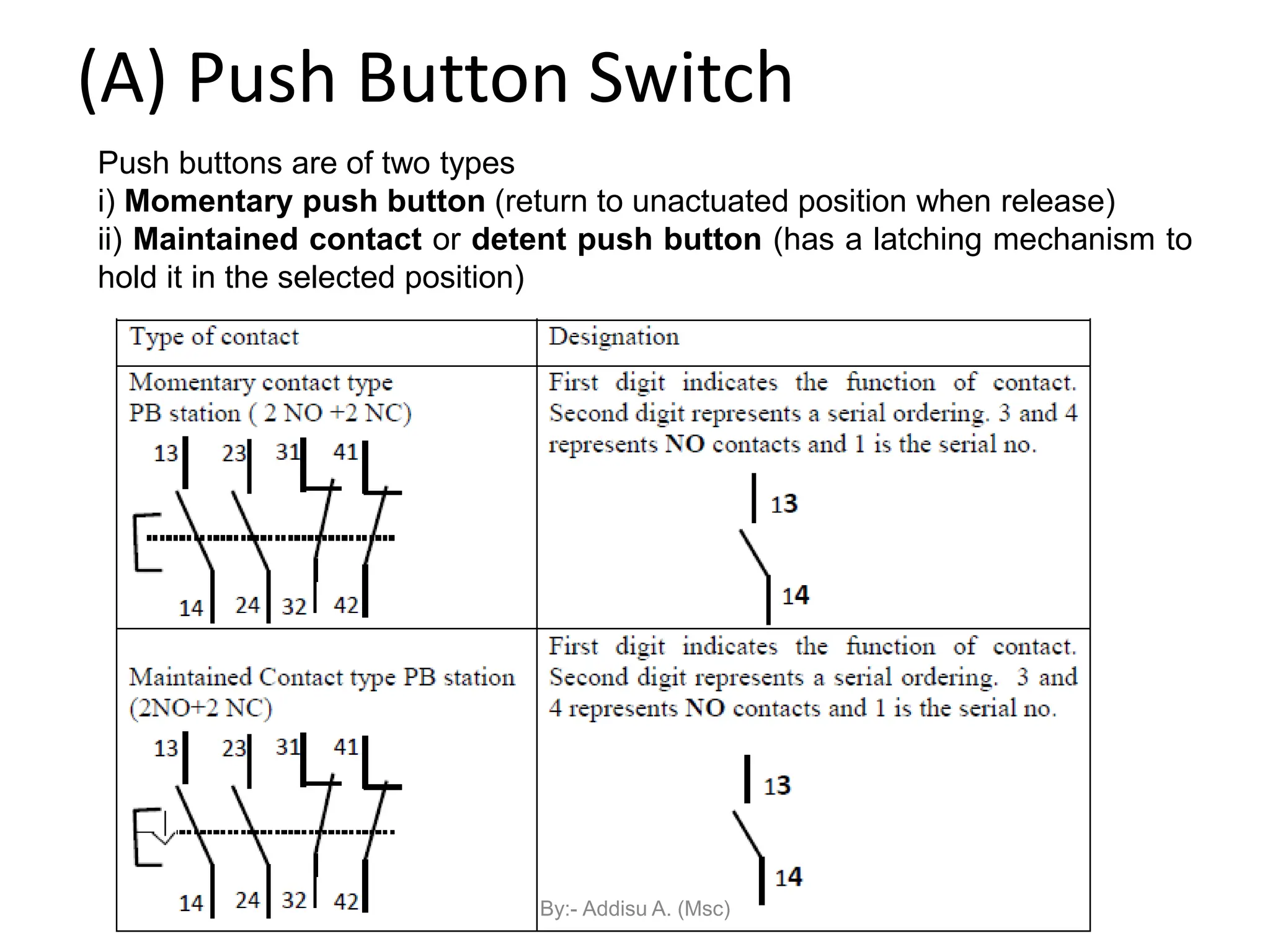

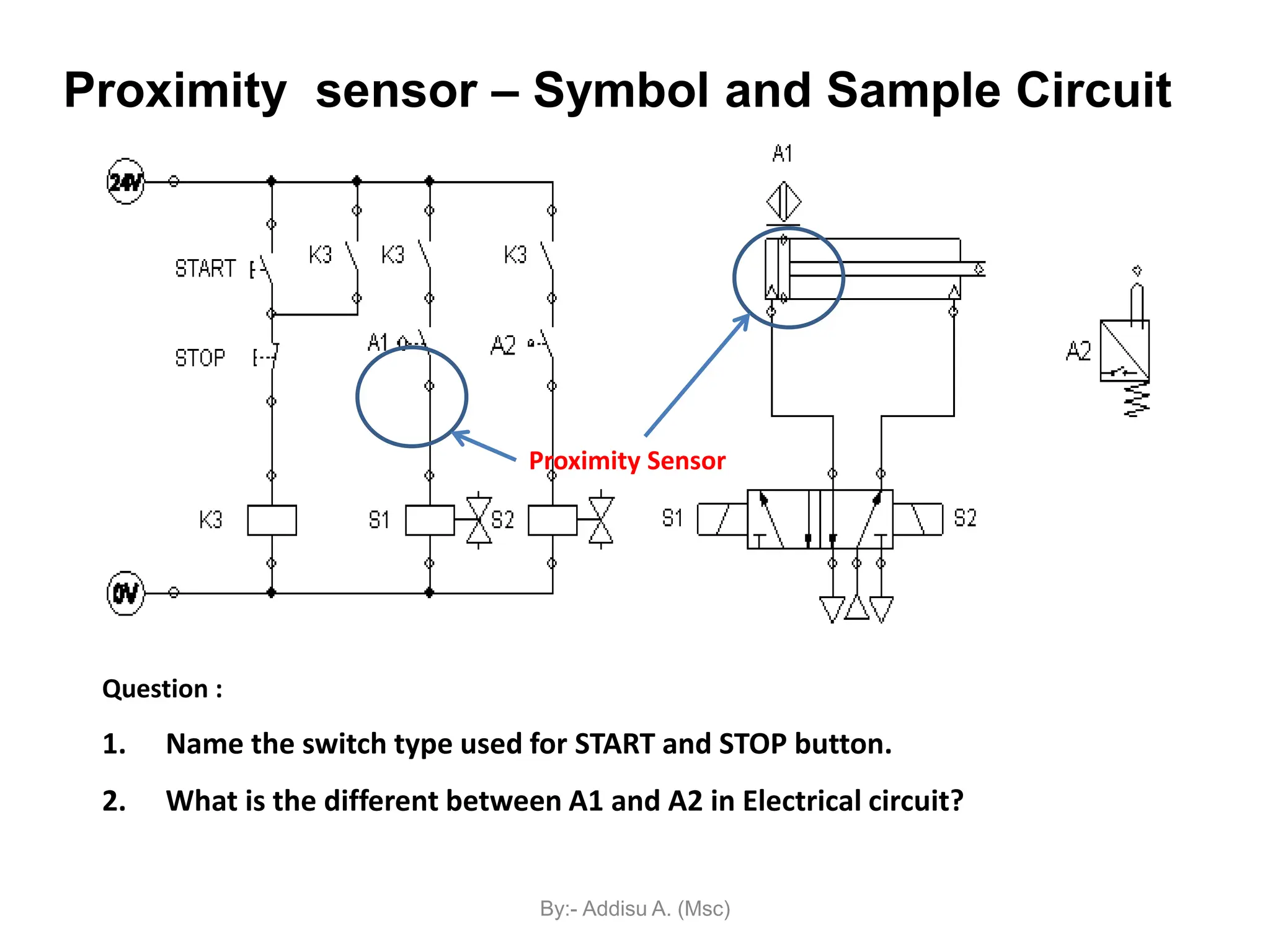

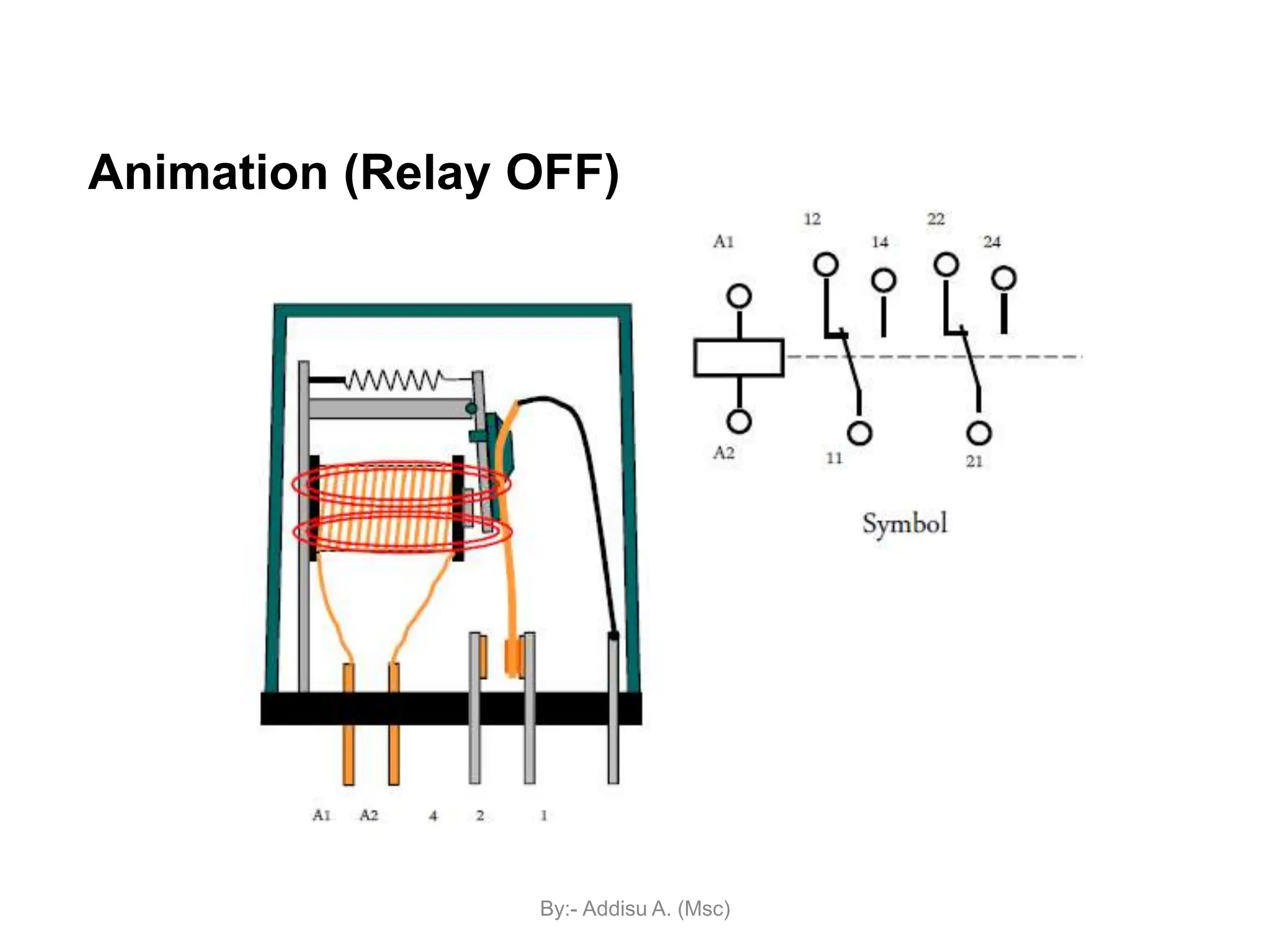

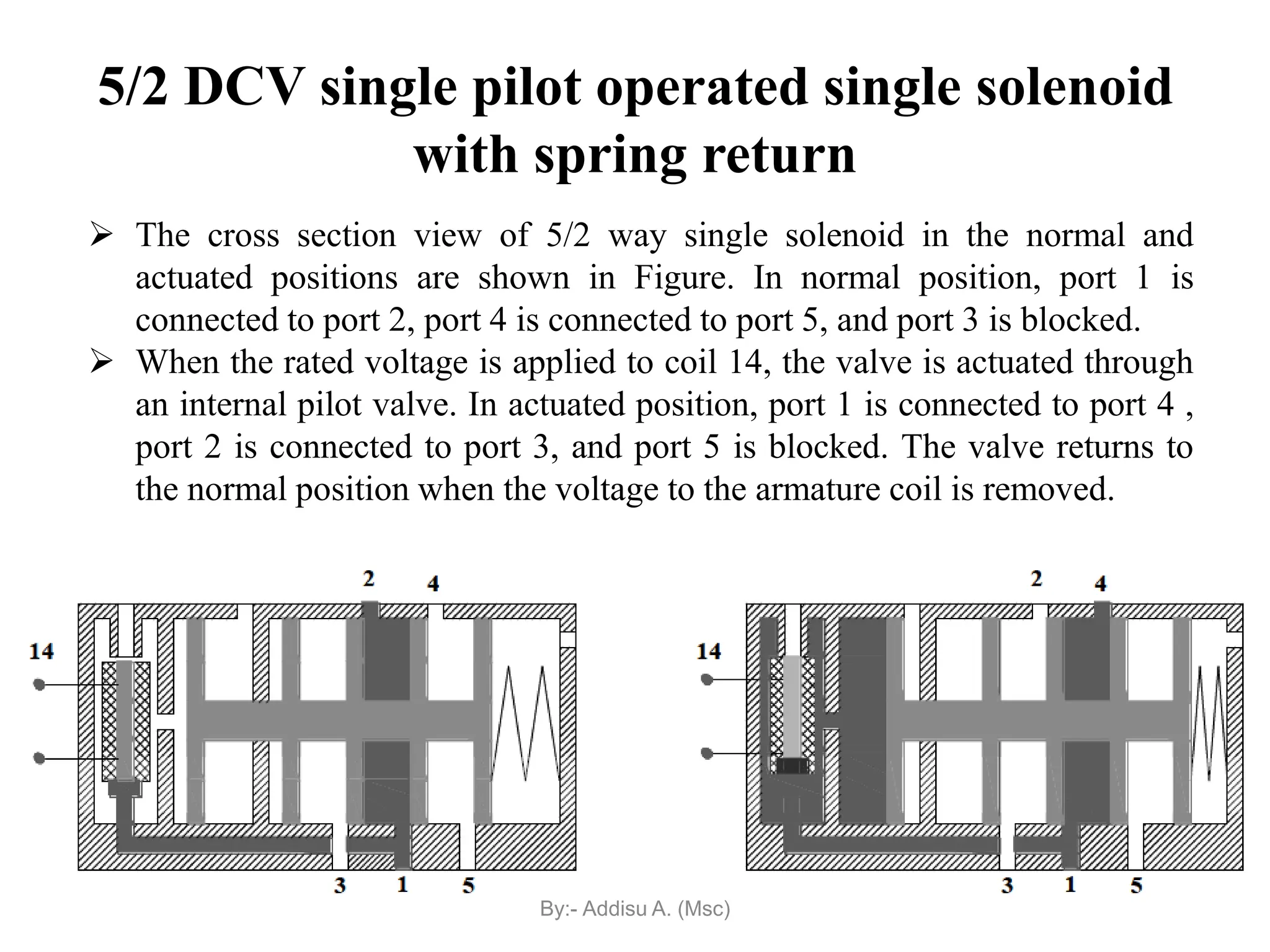

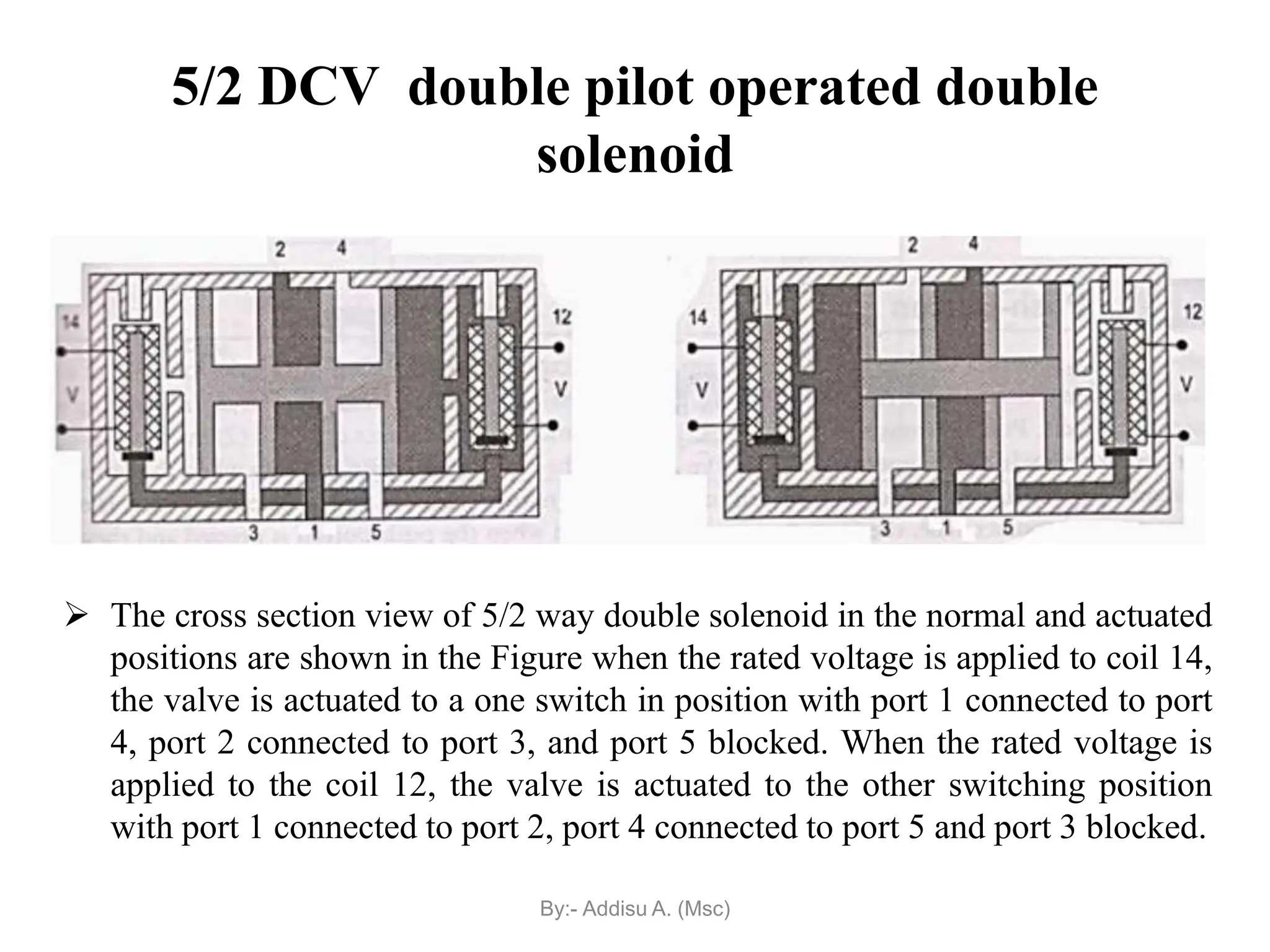

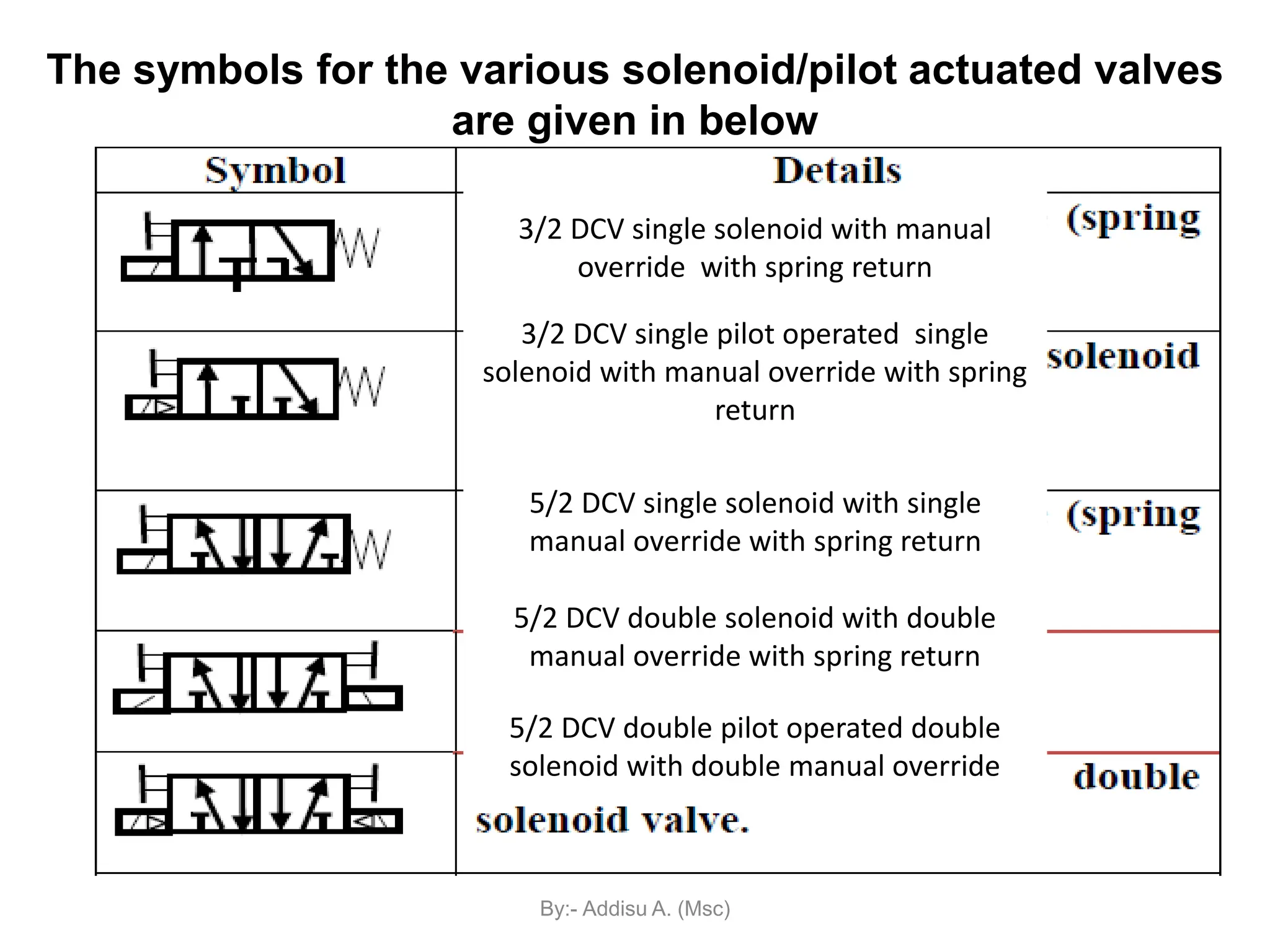

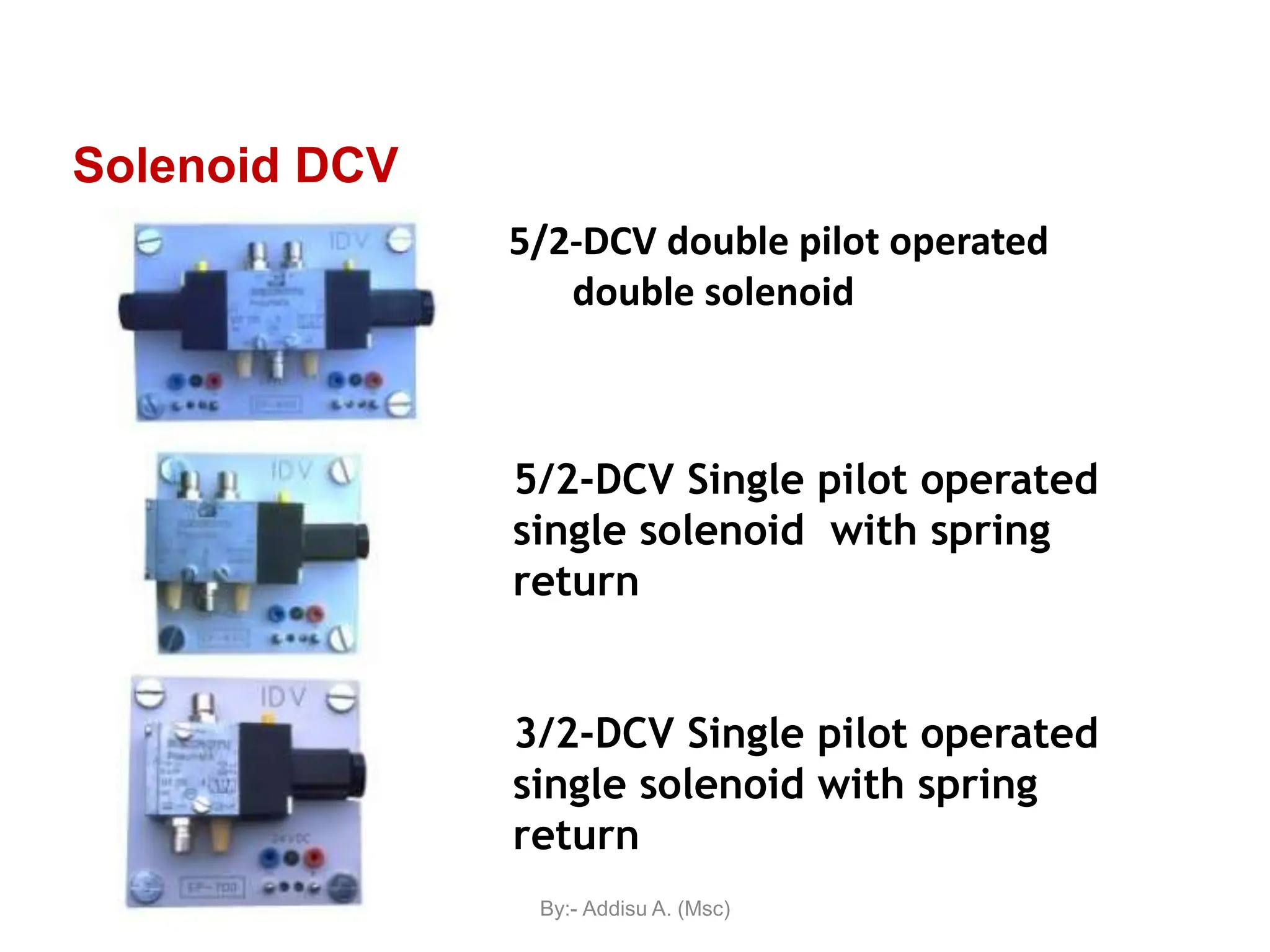

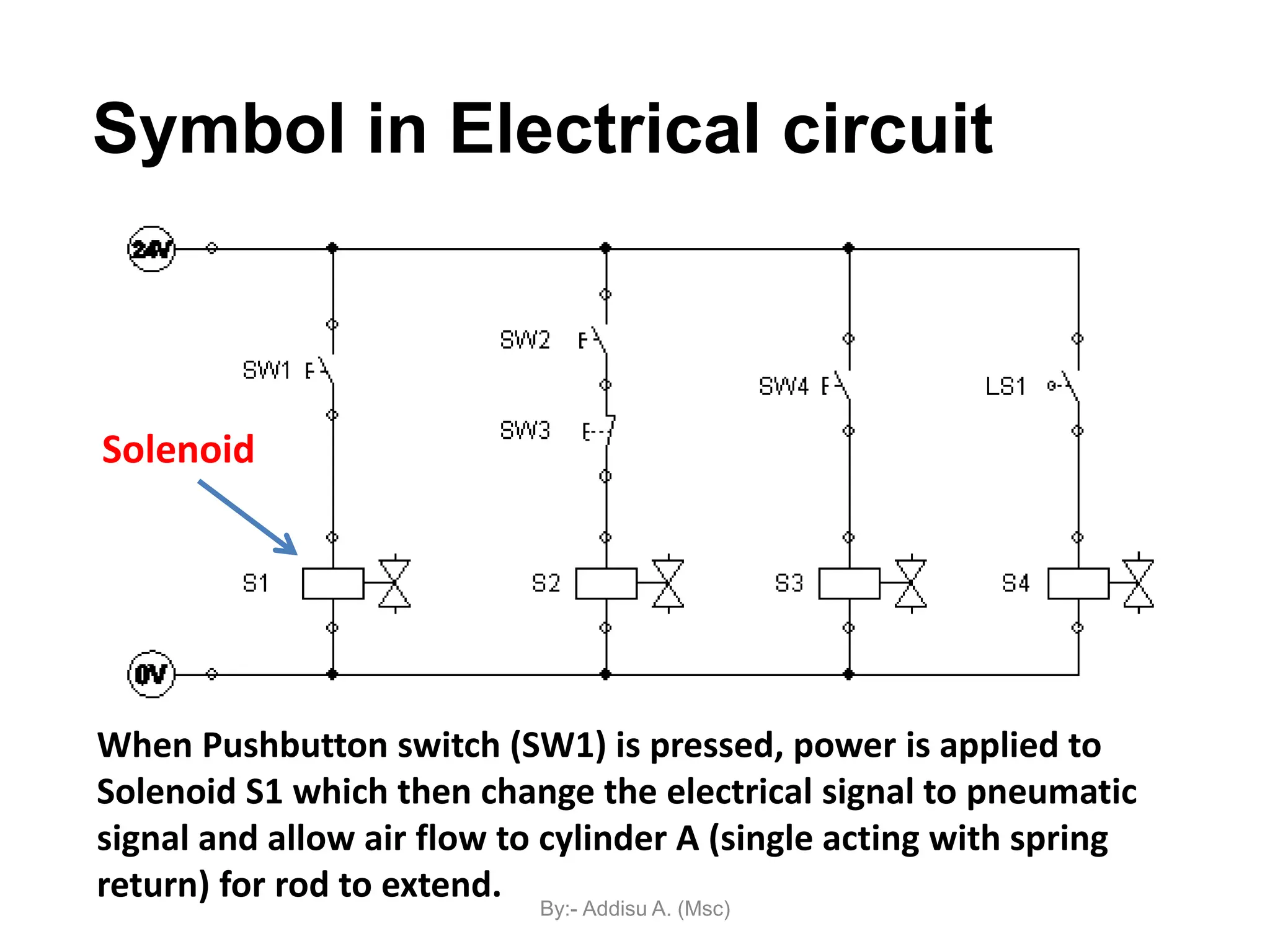

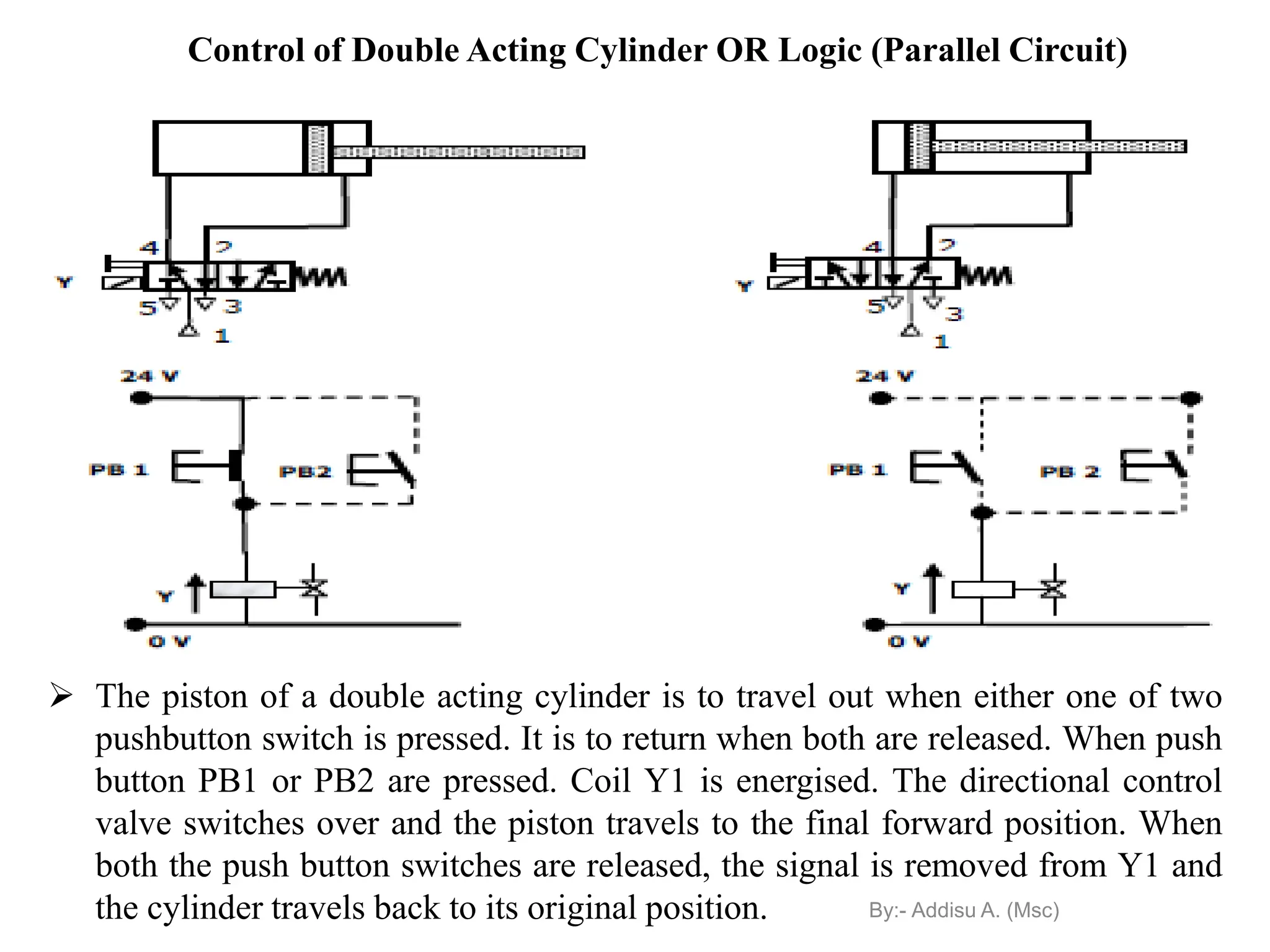

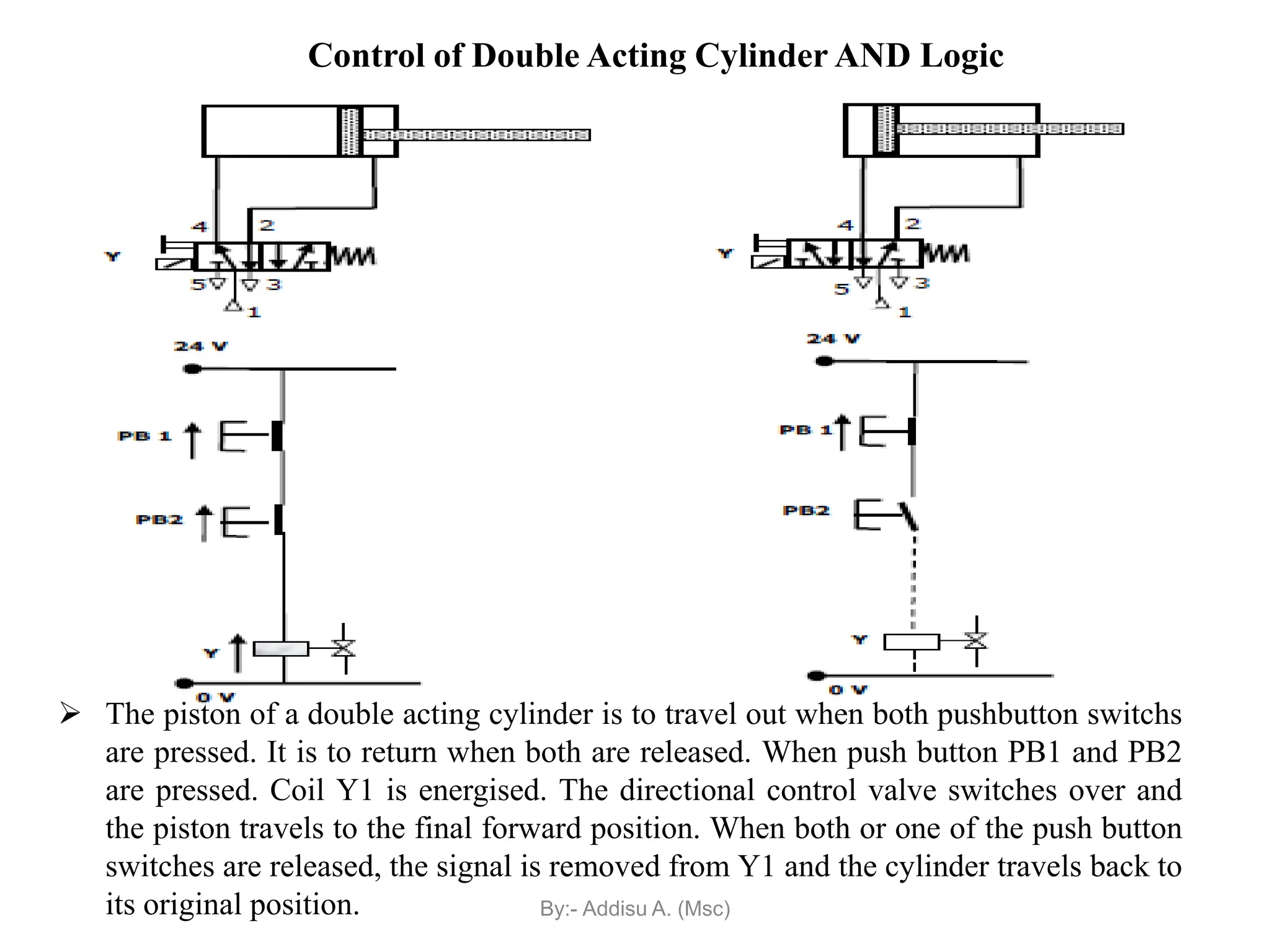

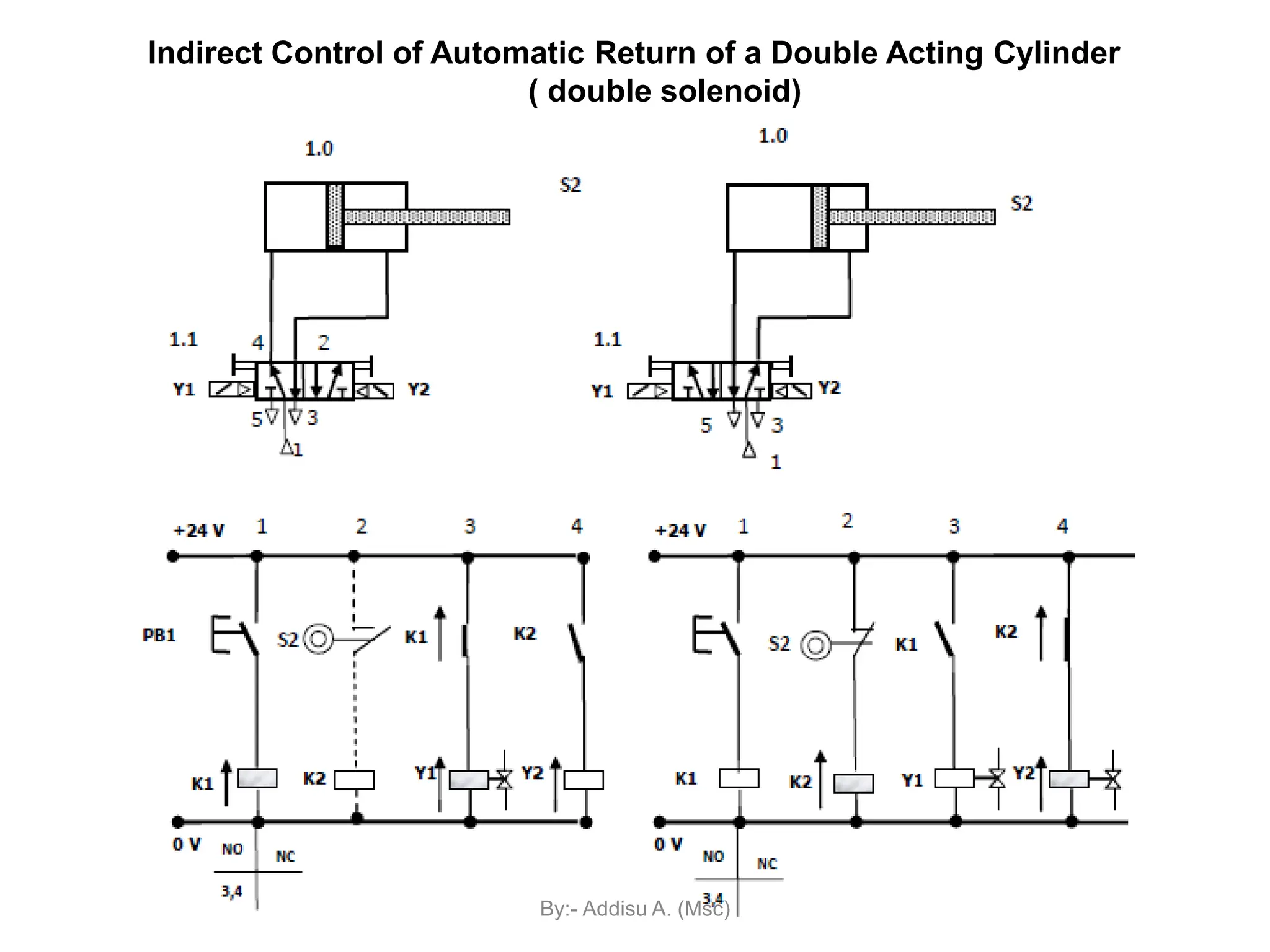

The document provides an introduction to electro-pneumatics, which integrates electrical and mechanical components with compressed air for controlling pneumatic systems through electrical currents. It covers the fundamentals of pneumatic systems, control methods, various electrical devices used, and the functioning and advantages of solenoid valves and relays. The text also discusses direct and indirect control methods for single and double acting cylinders in electro-pneumatic systems.