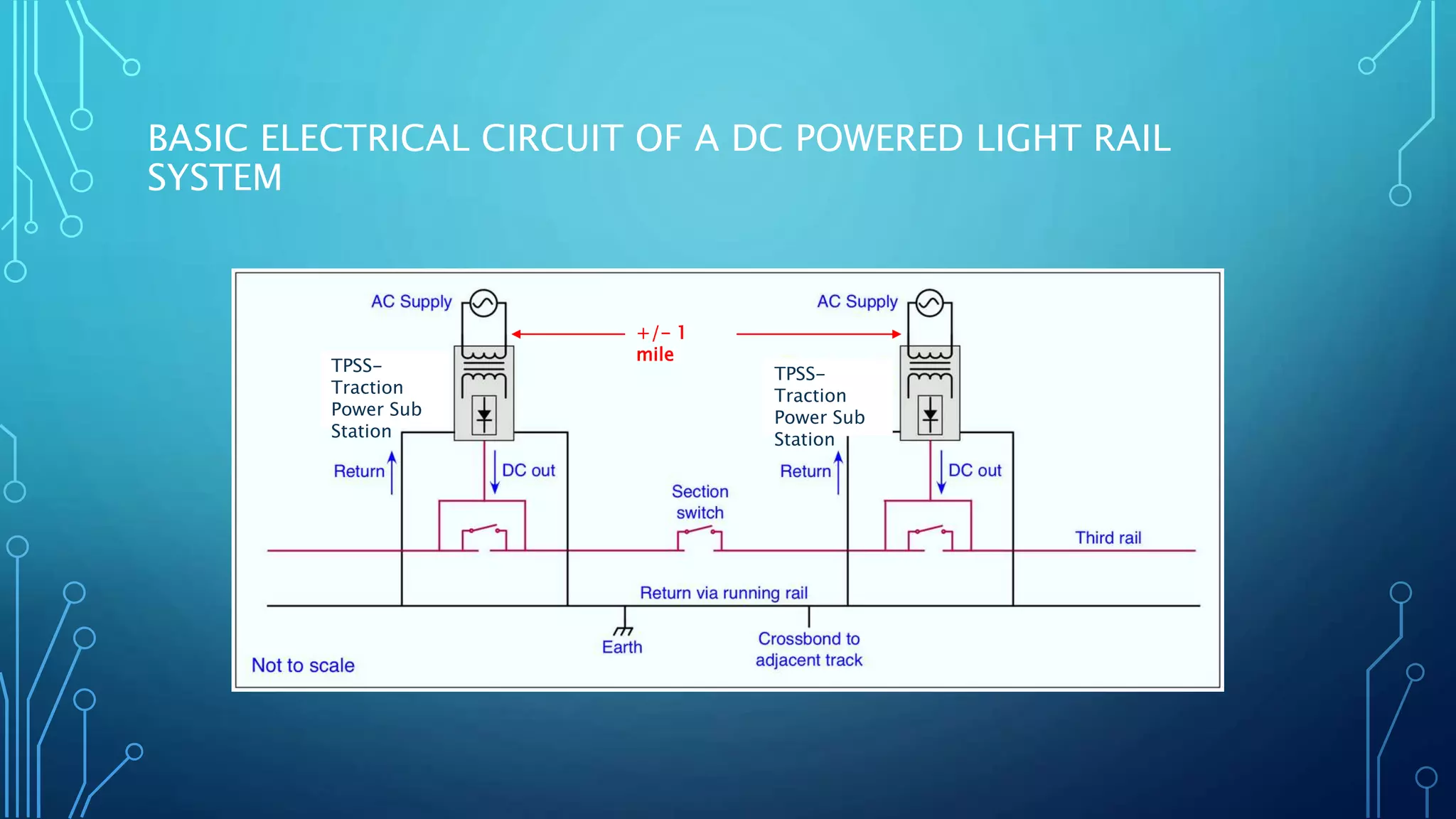

This document discusses stray current interference corrosion from DC transit systems like light rail. It defines stray current as current through unintended paths that can cause metal deterioration. DC systems use large currents that can damage nearby pipes and other structures through stray current discharge. Proper design, maintenance, and testing of track electrical isolation, as well as cathodic protection of adjacent structures, can help mitigate stray current corrosion. Maintaining high track-to-earth resistance is also important to protect from dynamic stray current damage.