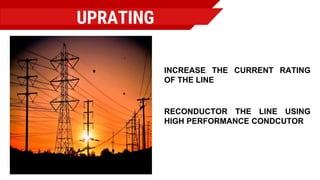

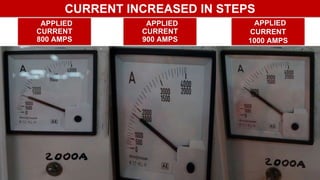

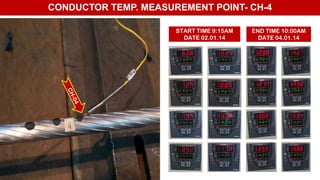

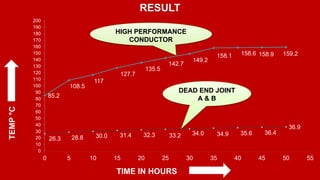

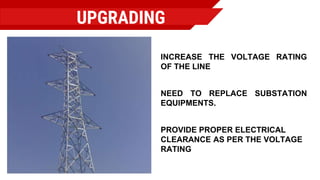

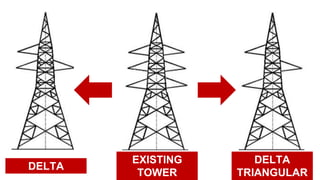

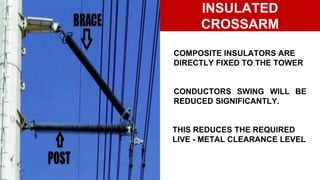

The document discusses the technical advantages of uprating existing transmission lines instead of constructing new ones, emphasizing minimized costs and environmental impact. It highlights the use of high-performance conductors to increase current ratings and the importance of equipment upgrades in maintaining safety clearances. Additionally, the implementation of modular designs reduces shutdown times during reconductoring, making uprating a cost-effective solution for handling increased load demands.