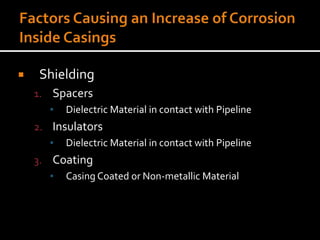

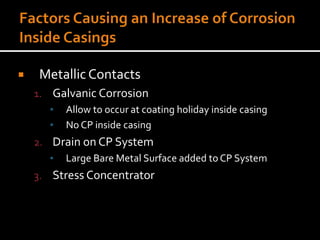

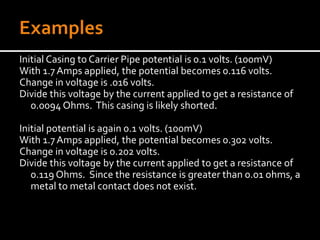

The document discusses various electrical tests that can be used to identify potential problems with pipeline casings and determine if a casing is shorted or isolated from the carrier pipe. These include potential surveys, internal resistance tests, four-wire IR drop tests, cycling rectifier tests, and casing depolarization tests. The results of these tests are analyzed to evaluate if a metal-to-metal contact exists between the casing and carrier pipe. Identifying shorted casings is important to prevent corrosion and ensure proper cathodic protection.