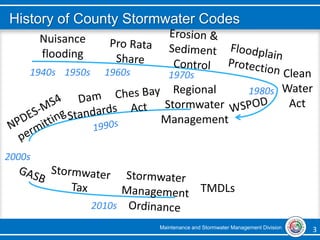

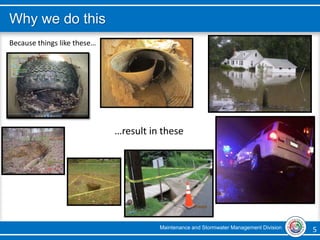

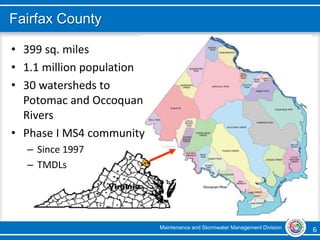

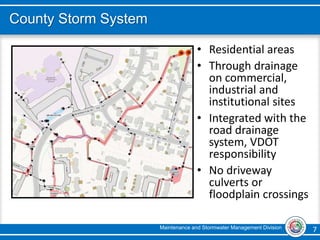

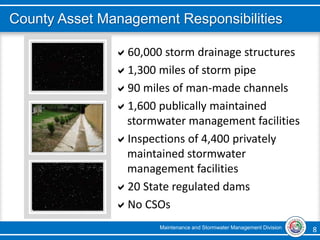

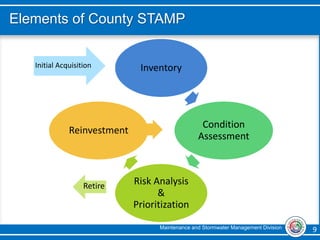

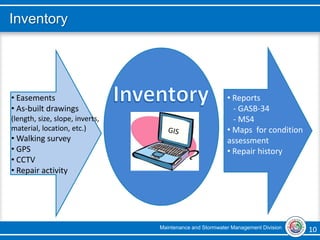

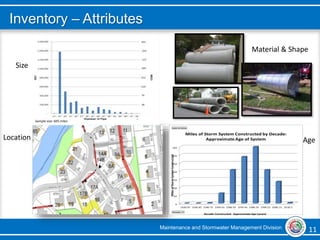

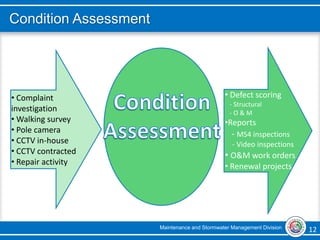

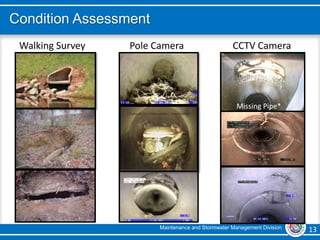

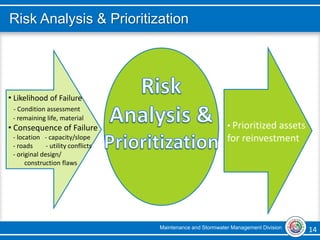

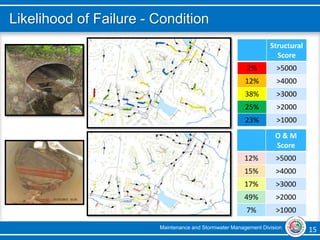

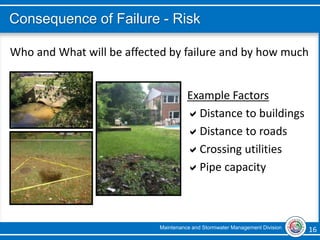

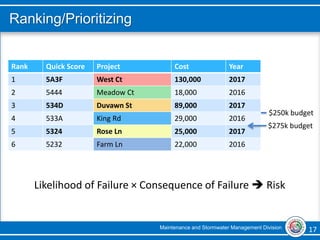

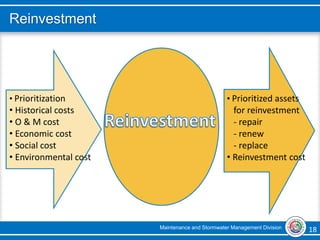

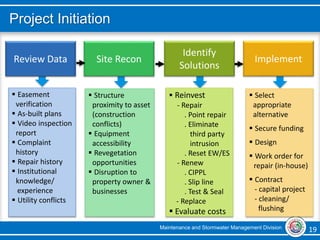

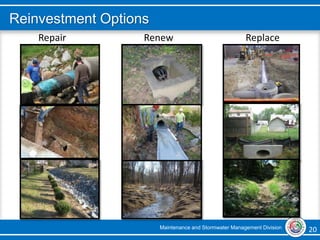

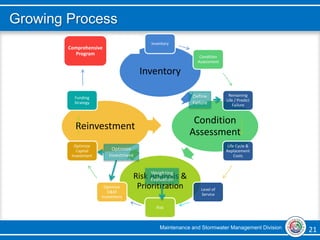

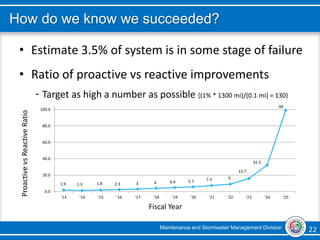

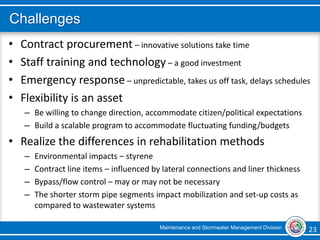

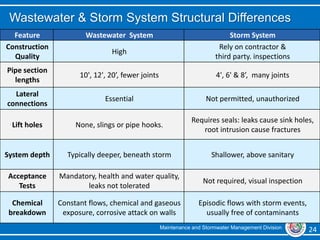

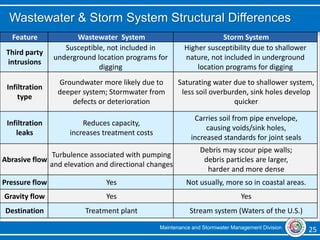

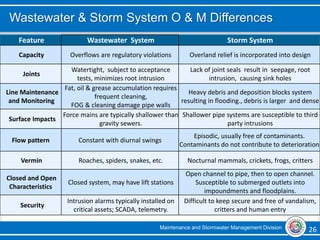

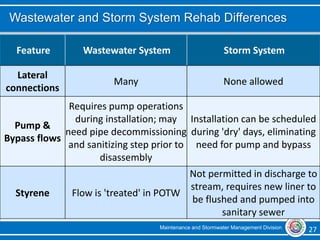

The document outlines the stormwater infrastructure management strategies in Fairfax County, VA, detailing the comprehensive asset management program aimed at maintaining and reinvesting in storm drainage systems. It highlights the county's responsibilities, historical context of stormwater management, and the structured approach for inventory, condition assessment, and risk analysis. Challenges, reinvestment options, and differences between wastewater and storm systems are also discussed to inform future planning and resource allocation.