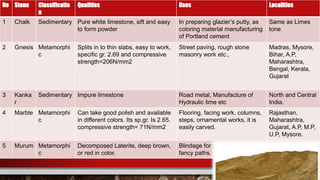

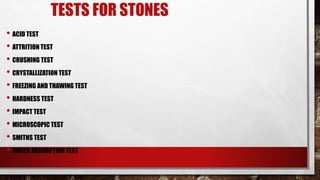

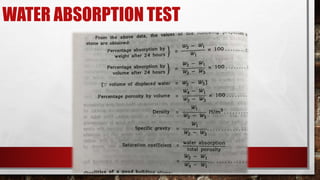

This document provides information on various types of building stones and their properties. It discusses igneous, sedimentary, and metamorphic rocks that are commonly used as building stones. Granite, basalt, sandstone, limestone and laterite are some of the principal stones described in terms of their occurrence, specific gravity, compressive strength, and common uses in construction. The document also outlines ideal properties for building stones and describes various tests conducted on stones.