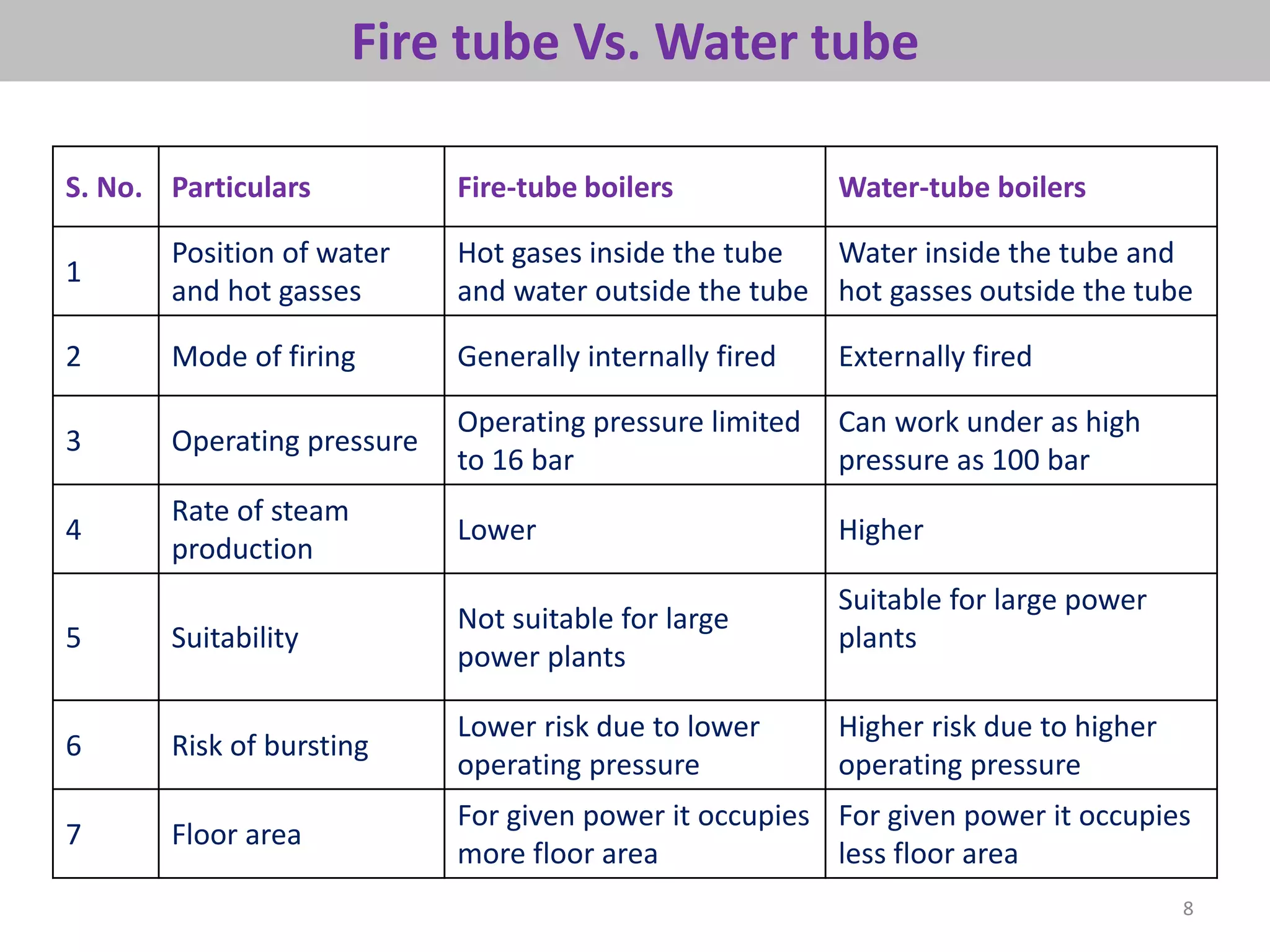

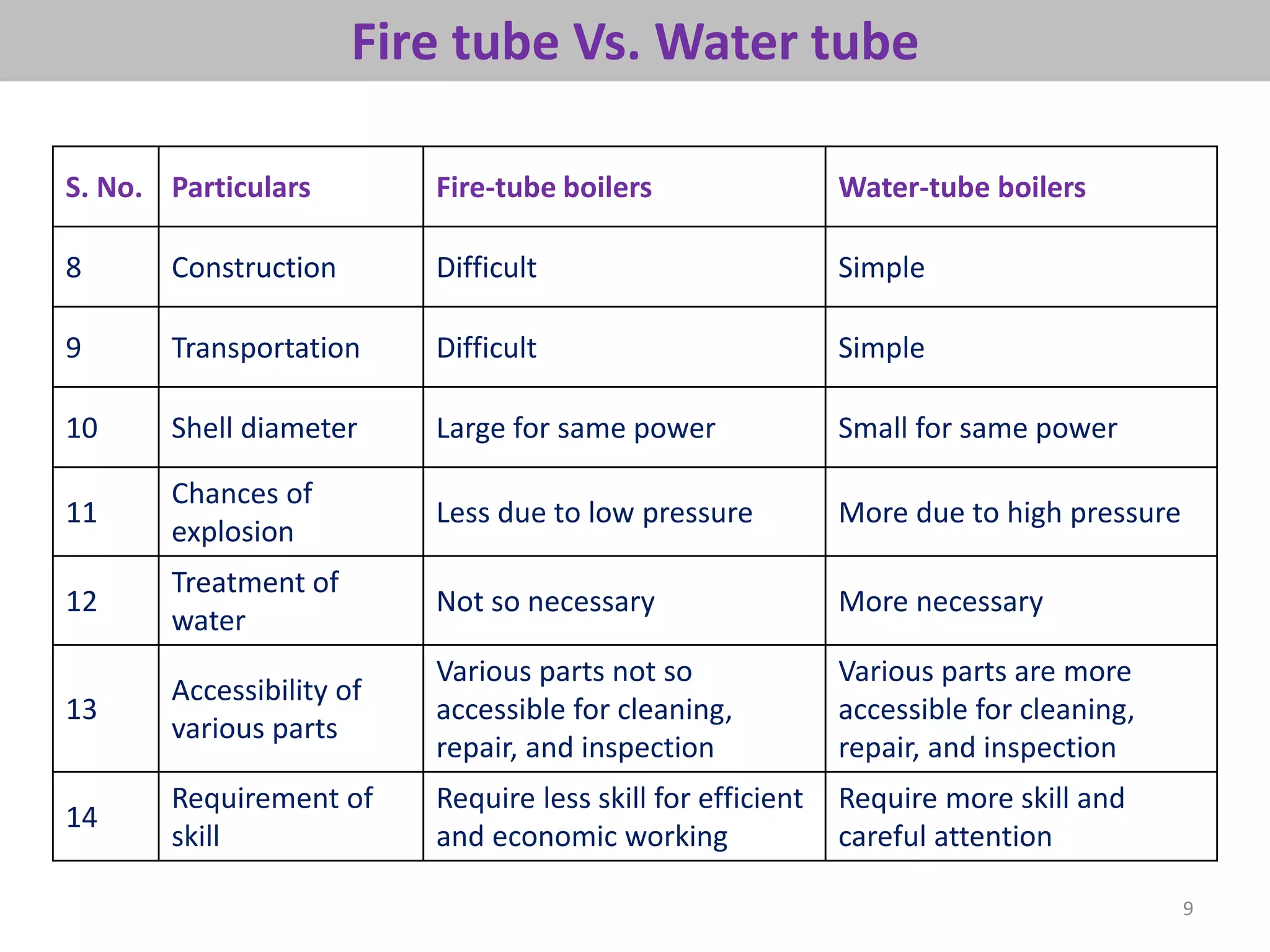

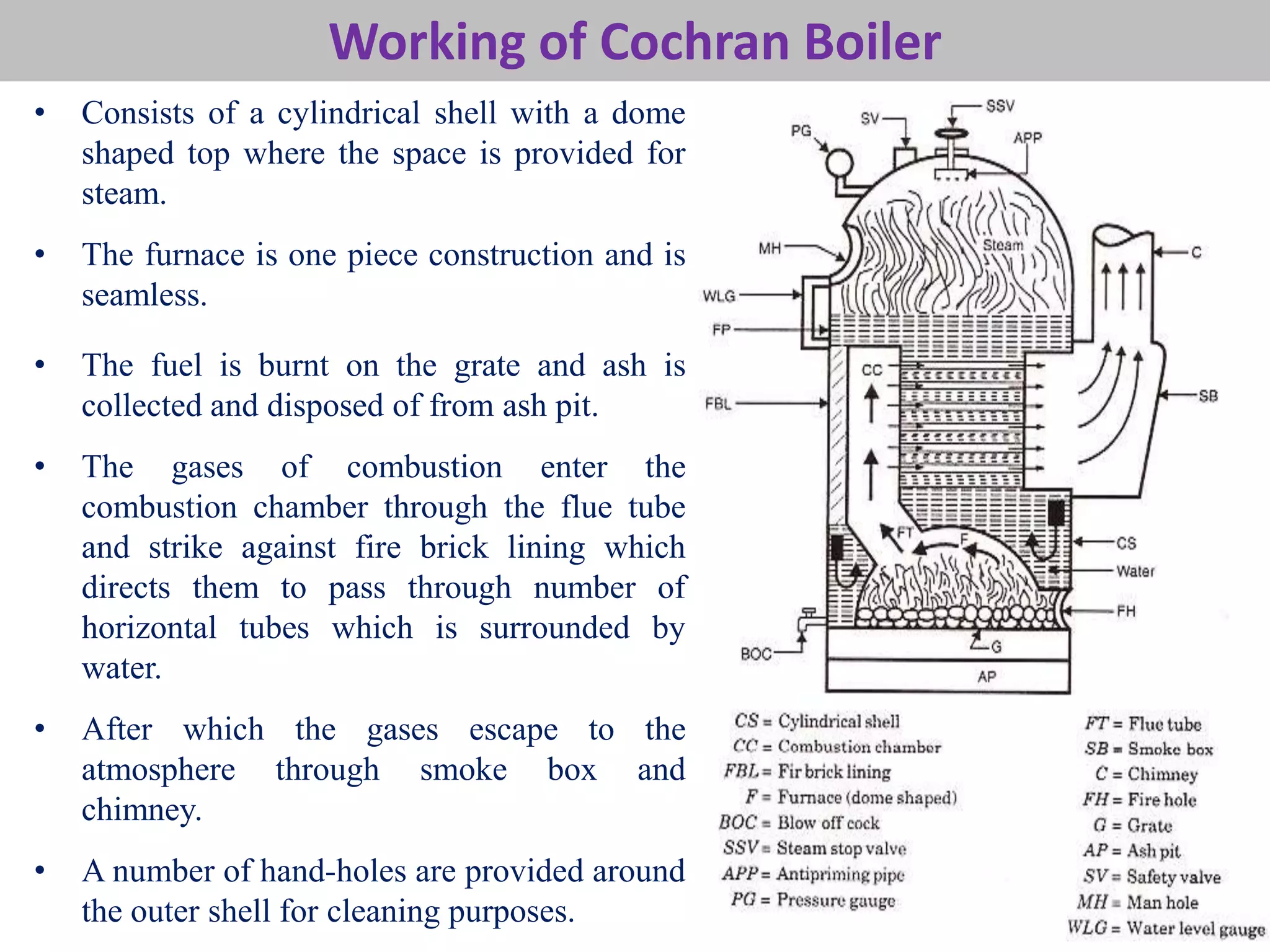

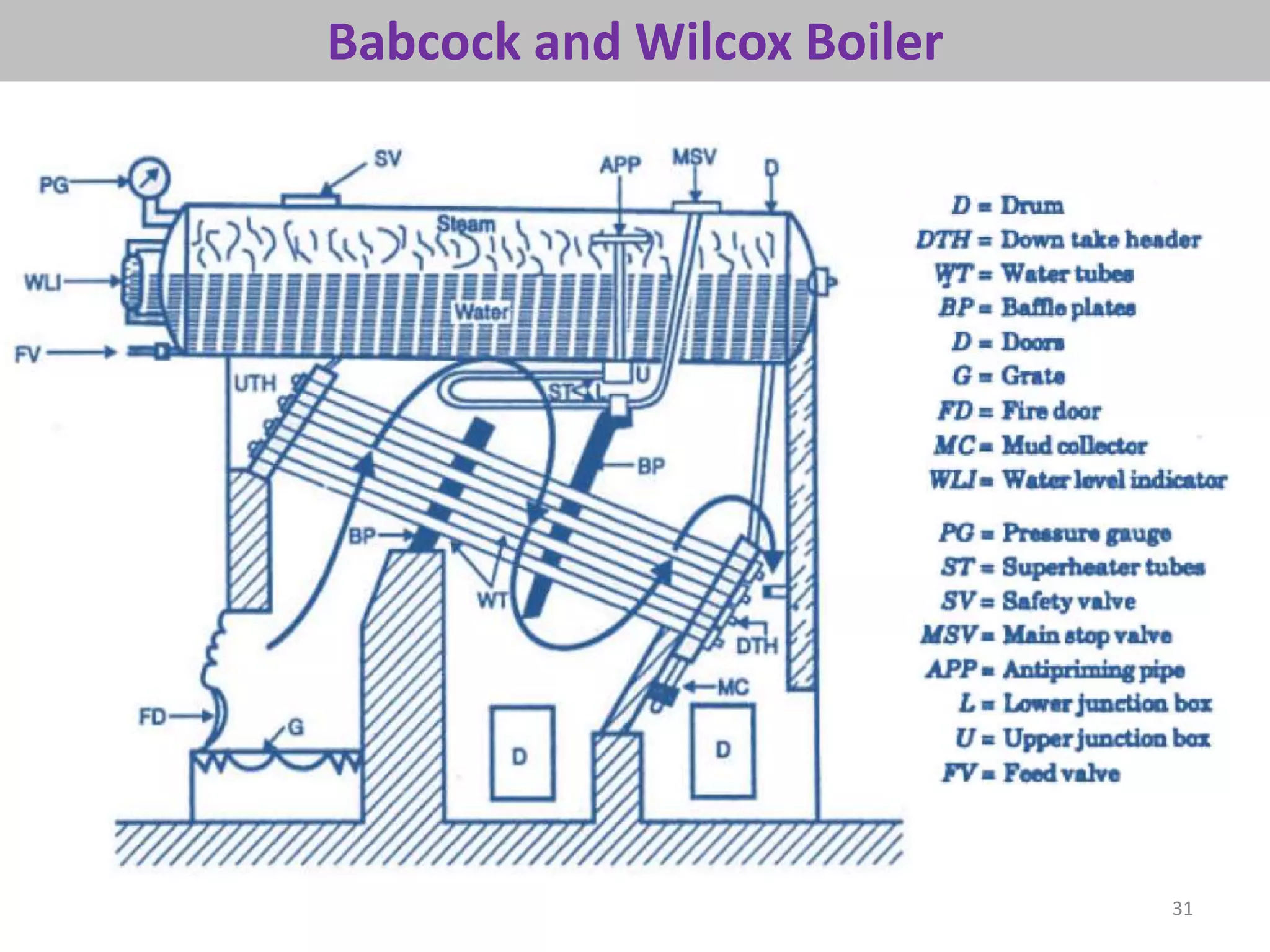

The document discusses steam generators/boilers. It defines a boiler as a closed vessel that produces steam from water via fuel combustion. It describes common boiler applications like power generation, heating, and industrial processes. It then classifies and describes different types of boilers, including fire tube versus water tube boilers, and provides details on specific fire tube boiler designs like the Cochran and Lancashire boilers.