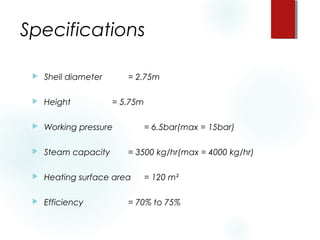

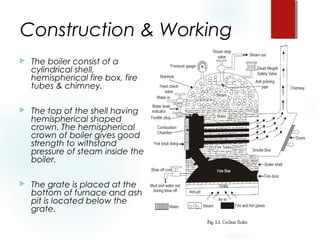

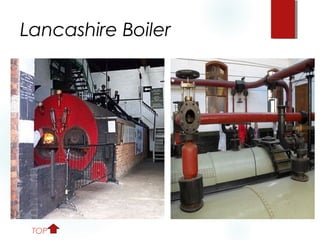

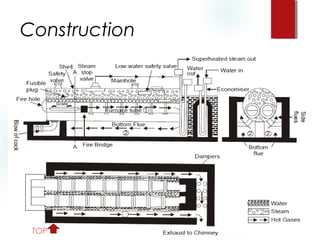

The document summarizes two types of boilers: the Cochran boiler and the Lancashire boiler. The Cochran boiler is a vertical, multi-tube, fire tube boiler that is portable with a small floor area. It has a shell diameter of 2.75m, height of 5.75m, and can produce 3500 kg/hr of steam. The Lancashire boiler is a horizontal, stationary boiler commonly used in industries. It is longer than the Cochran boiler at 7-9m in length and can produce 9000 kg/hr of steam. Both boilers use fire tubes for heat transfer and have similar components like safety valves, but the Lancashire boiler has a larger heating surface area due to its three-pass design