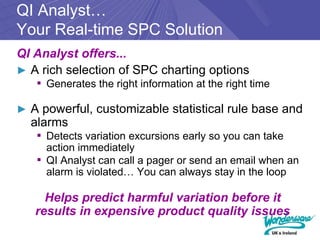

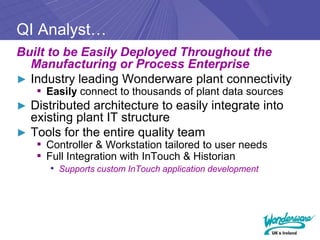

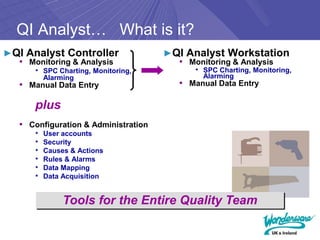

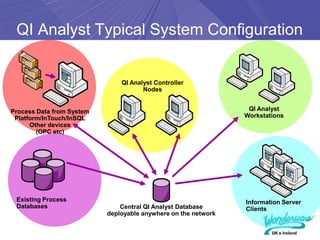

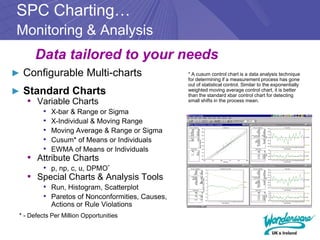

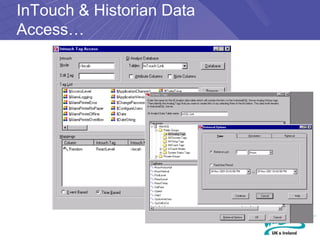

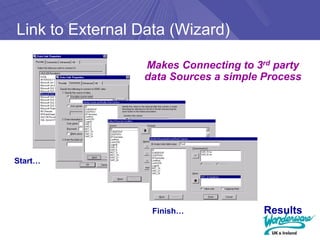

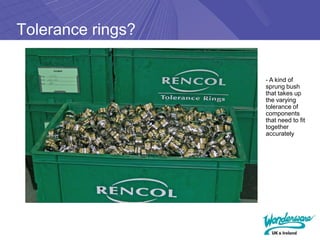

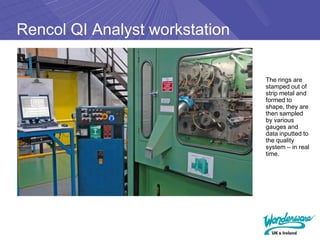

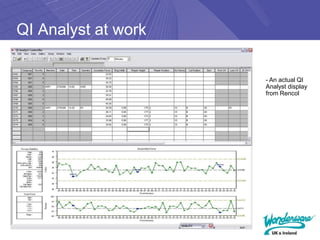

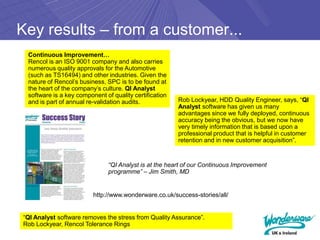

The Wonderware interactive webinar series introduces Qi Analyst 8.0, a real-time statistical process control (SPC) solution designed to enhance quality management and reduce production costs by monitoring and predicting quality variations. The document outlines the features and benefits of Qi Analyst, including its integration capabilities, alarm systems, and user-friendly charting options that support quality improvement initiatives such as Six Sigma and Total Quality Management. A case study demonstrates successful implementation at Rencol Tolerance Rings, showcasing improved quality assurance processes and customer satisfaction through the use of this software.