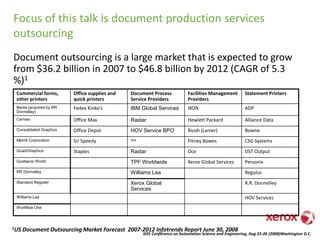

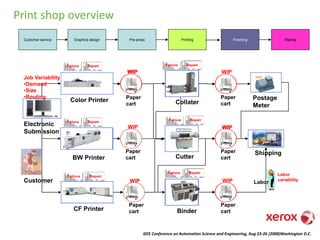

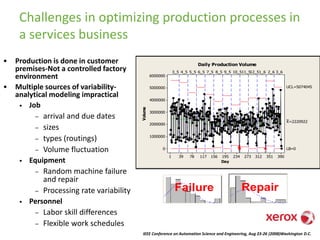

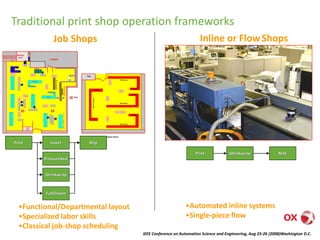

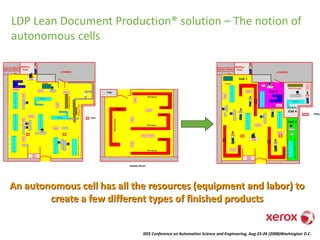

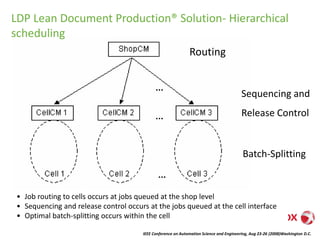

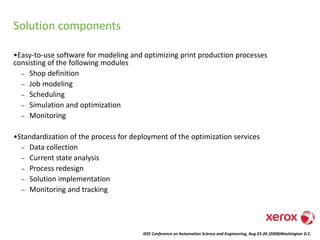

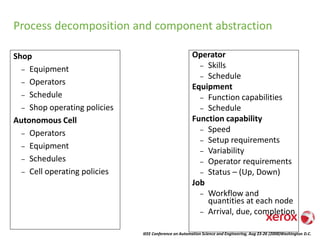

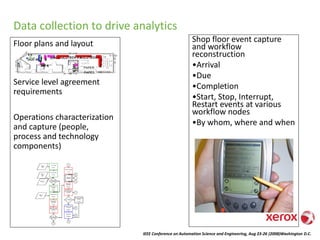

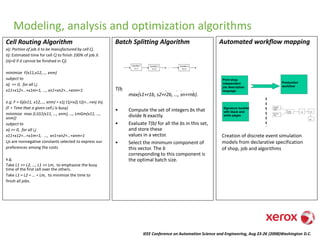

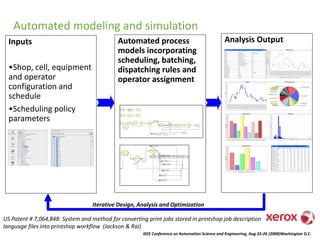

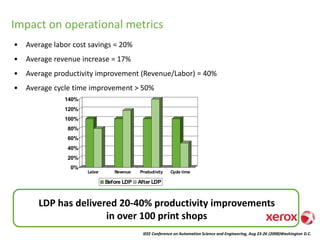

The document discusses how process optimization solutions were developed and delivered at scale to Xerox's document production outsourcing services business. An automated software toolkit was created that encapsulates advanced analytics, process modeling, optimization, and scheduling techniques. This allowed the delivery of process optimization services using less skilled personnel and enabled significant cost savings and improved customer satisfaction. The key aspects of the solution included modeling different components of the print production process, collecting shop floor data, and developing algorithms and modules for simulation, optimization, and monitoring.