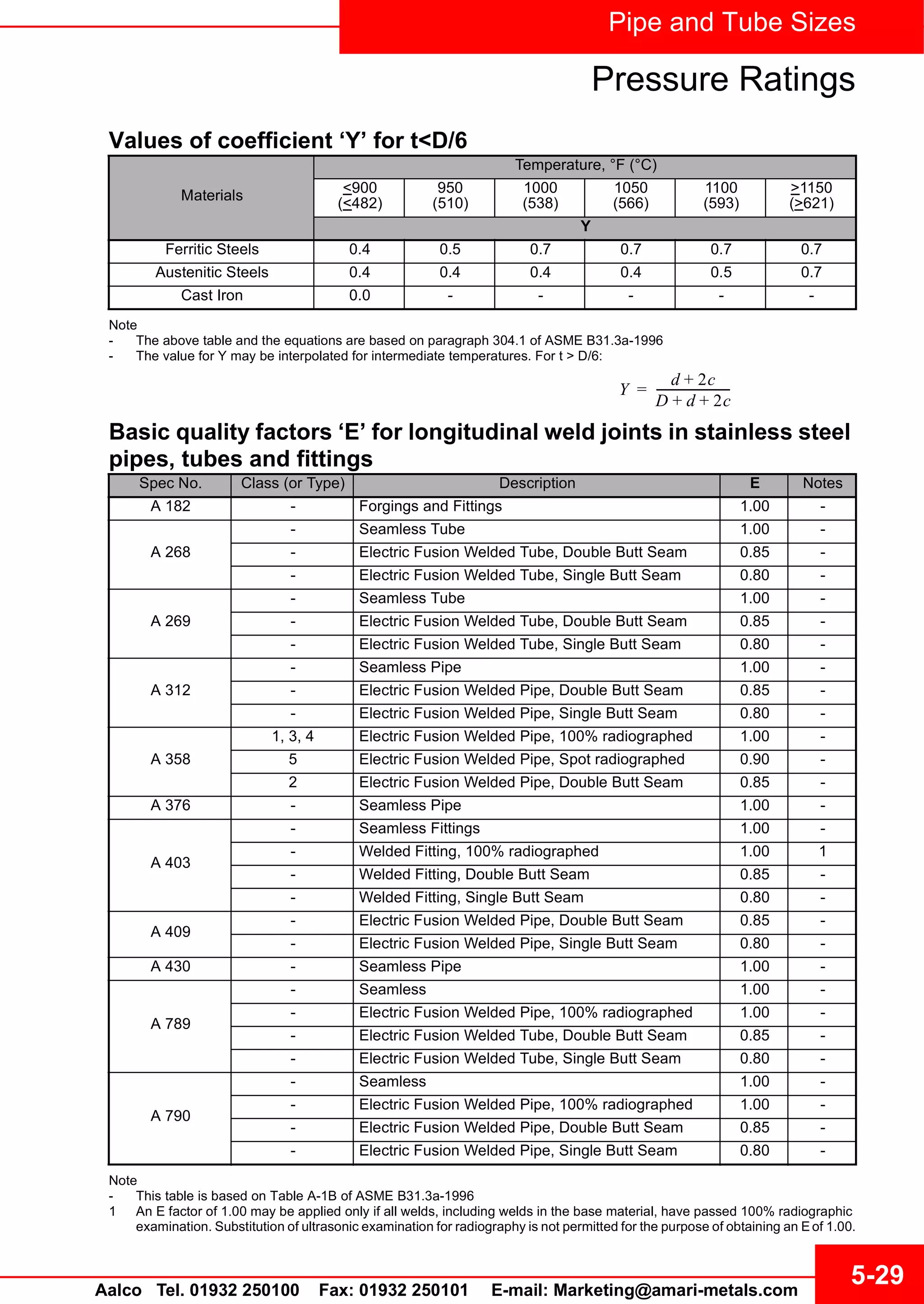

This document provides information on calculating pressure ratings for stainless steel pipe and tube. It includes equations for determining the required wall thickness given an internal design pressure or for calculating the maximum allowable internal pressure given the wall thickness. Tables with material properties like stress values and quality factors are also included to aid in the calculations. Worked examples demonstrate how to use the equations and tables to size pipe or determine pressure ratings.