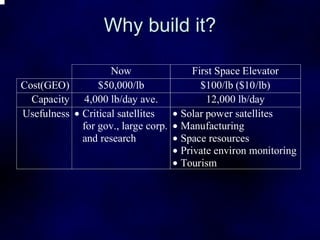

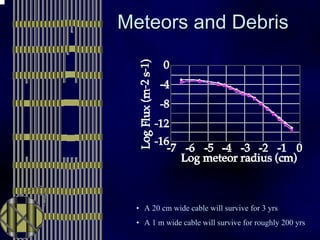

The document proposes building a space elevator using carbon nanotube composite materials to provide cheaper access to space. It describes a design for an initial small space elevator with a 20 ton capacity that could transport payloads to geosynchronous orbit in one week for $100 per pound, far cheaper than current options. The design addresses challenges like constructing a strong tether, deploying it into space, powering climbers, and anchoring it on Earth, which could be developed within a decade for under $10 billion. It concludes that a space elevator could transport over 5,000 kg of payload per day and ultimately cost just $10 per kg.