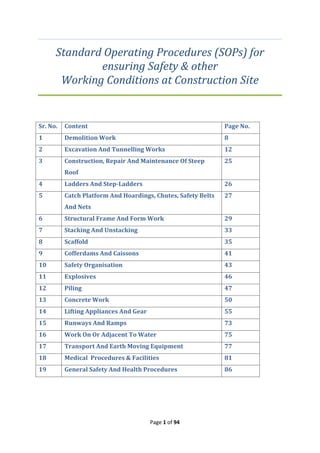

This document provides standard operating procedures for ensuring safety during demolition work at construction sites. It outlines procedures for preparing the site, protecting adjacent structures, demolishing walls and partitions safely, using safe methods of operation to remove debris, providing safe access to floors, and demolishing structural steel members column by column. The employer is responsible for examining adjacent structures, obtaining necessary permissions, protecting utilities, ensuring systematic and safe demolition work, providing safe footing and access, and not leaving unstable walls standing.