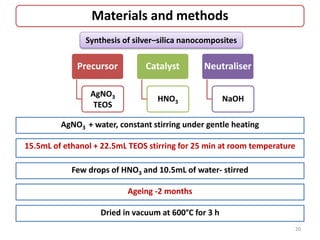

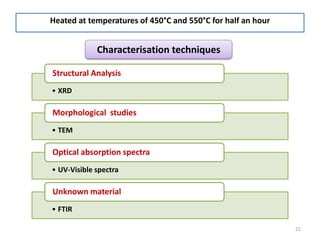

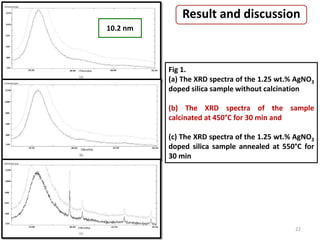

The document discusses sol-gel technology for creating nano-textiles, detailing the synthesis methods, applications, and characterization techniques involving nanoparticles. It highlights various studies on nanoparticles, particularly silver and zinc oxide, their antibacterial properties, and the integration with textiles for enhanced functionality. Additionally, it covers challenges and advantages in the sol-gel process, showcasing specific applications like antibacterial coatings and flame retardant features in textile manufacturing.

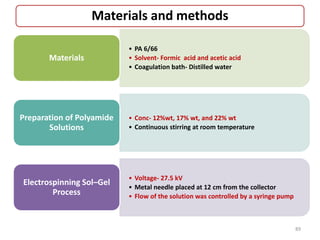

![Materials and methods

100% scoured & bleached cotton fabric

Diethylphosphatoethyltriethoxysilane (DPTS)

3-aminopropyltriethoxysilane (APTES)

1-hydroxyethane 1,1-diphosphonic acid

Melamine

Urea

Hydrochloric acid

Sodium hydroxide

Ethanol

N-hexakis-methoxymethyl- [1,3,5] triazine-2,4,6-triamine (MF)

Materials

Functional finishing of cotton fabric

APTES and DPTS were hydrolysed with HCl in deionized water,

vigorous stirring for 10 h at room temperature

55](https://image.slidesharecdn.com/seminarfin-191224094946/85/Sol-gel-technology-for-nano-textiles-55-320.jpg)

![Result and discussion 58

Diethylphosphatoethyltriethoxysilane (DPTS)

3-aminopropyltriethoxysilane (APTES)

N-hexakis-methoxymethyl- [1,3,5] triazine-2,4,6-triamine (MF)

Fig 17. TG curves of pure and treated cotton fabrics in nitrogen: Weight/% vs

Temperature/°C](https://image.slidesharecdn.com/seminarfin-191224094946/85/Sol-gel-technology-for-nano-textiles-58-320.jpg)

![59

Sample Residue at

360°C [%]

Residue at

750°C [%]

Untreated

cotton

14 2

DPTS 53 23

APTES 41 8

DPTS-APTES05 56 27

DPTS-APTES1 57 22

DPTS-APTES2 60 21

MF30 39 3

MF60 37 5

MF90 31 4

DPTS-MF1 60 20

DPTS-MF2 60 29

DPTS-MF3 60 33

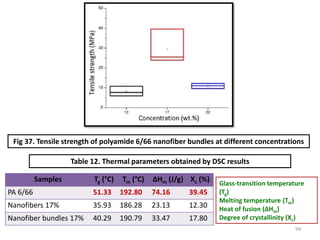

Sample Total

burning

time [s]

Burning

Rate [mm/s]

Residue

[%]

Untreated

cotton

33 10 -

DPTS 35 6 37

APTES 24 7 33

DPTS-APTES05 21 10 60

DPTS-APTES1 20 9 48

DPTS-APTES2 24 8 53

MF30 150 10 27

MF60 51 12 19

MF90 28 8 20

DPTS-MF1 17 10 79

DPTS-MF2 19 8 68

DPTS-MF3 23 7 66

Table 6. Collected data of untreated

and treated fabrics by flammability

tests

Table 5. TGA data of untreated and

treated cotton fabrics in air

Diethylphosphatoethyltriethoxysilane (DPTS)

3-aminopropyltriethoxysilane (APTES)

N-hexakis-methoxymethyl- [1,3,5] triazine-2,4,6-triamine (MF)](https://image.slidesharecdn.com/seminarfin-191224094946/85/Sol-gel-technology-for-nano-textiles-59-320.jpg)

![60

Table 7. Flammability data

Sample Total burning time [s] Residue [%]

Untreated cotton 36 -

Only DPTS (O_D) 24 25

Only bisphosphonate (O_P) 23 10

Only melanine (O_M) 25 2.0

Only urea (O_U) 36 2.0

DPTS- bisphosphonate

combi (D_P)

38 40

DPTS- melamine combi

(D_M)

15 24

DPTS- urea combi (D_U) 25 22

Diethylphosphatoethyltriethoxysilane (DPTS)](https://image.slidesharecdn.com/seminarfin-191224094946/85/Sol-gel-technology-for-nano-textiles-60-320.jpg)