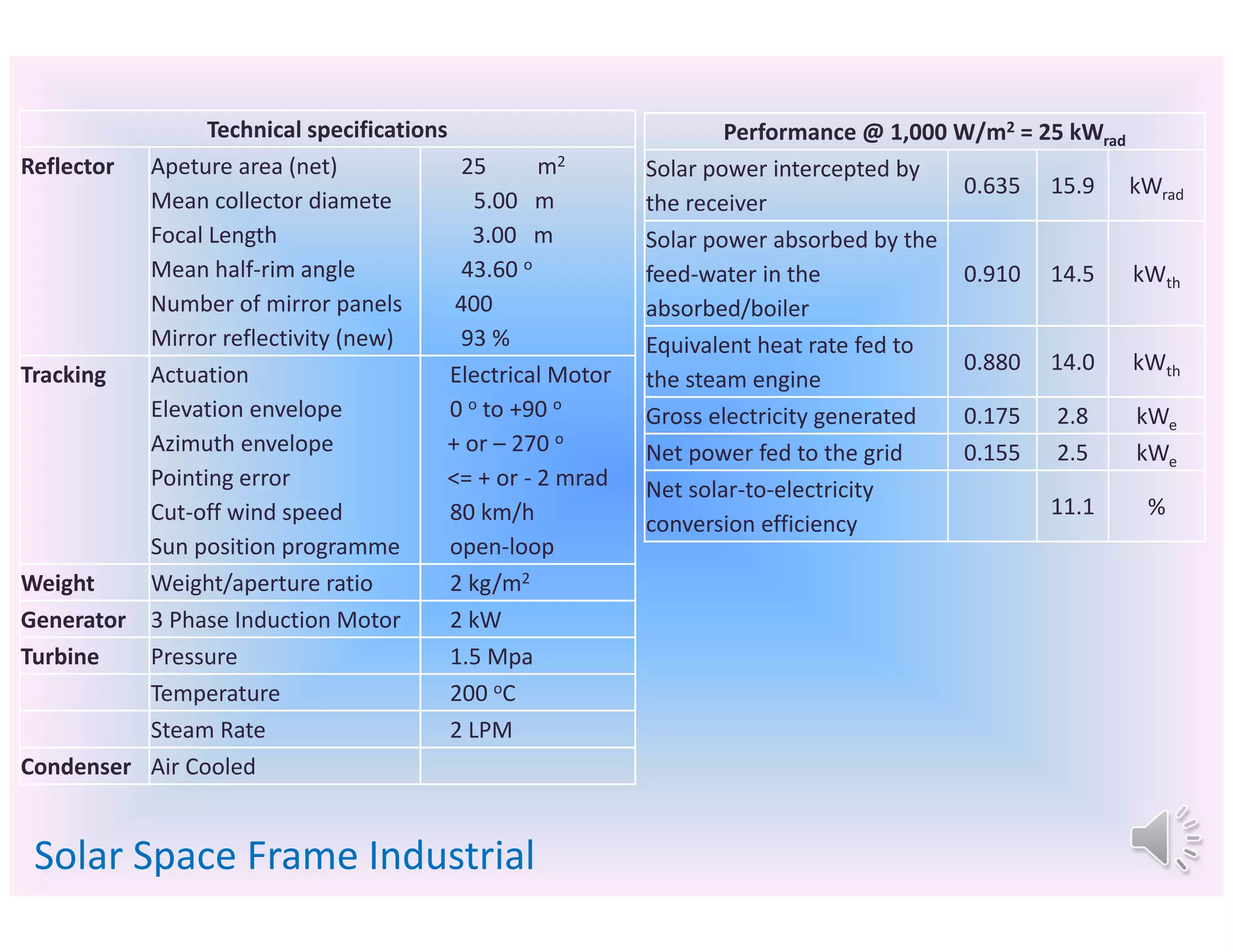

The document summarizes a solar steam turbine system equipped with concentrating solar power (CSP) technology specially designed for medium solar insolations in humid tropical countries. The parabolic dish systems use satellite-like mirror dishes to focus light onto a central receiver, achieving high conversion efficiencies up to 30%. A 10-25 kW system has a 10 meter diameter dish. It can run individually or be grouped for small or utility-scale power applications, though intermittent clouds can weaken the concentrated solar flux.