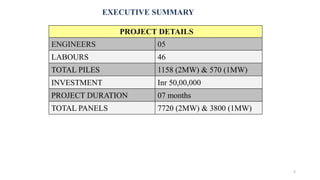

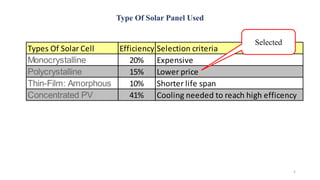

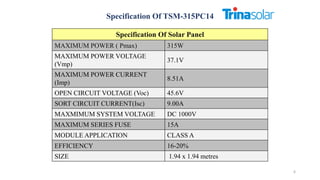

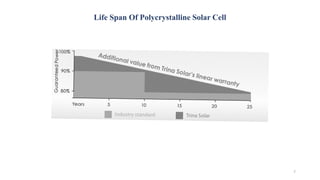

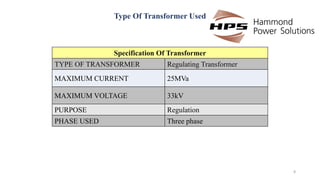

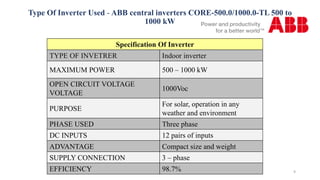

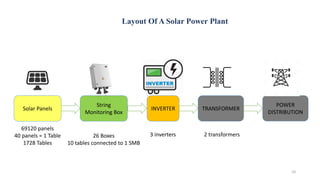

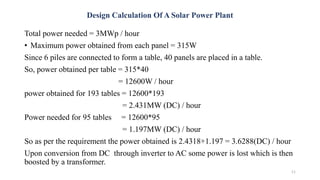

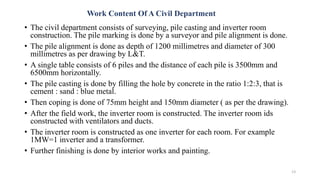

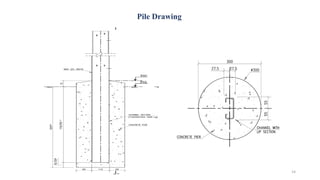

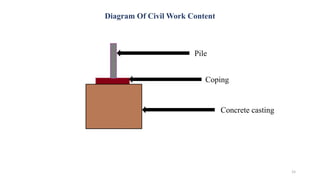

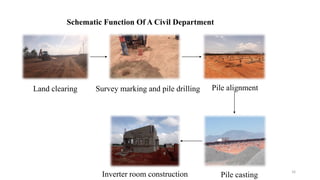

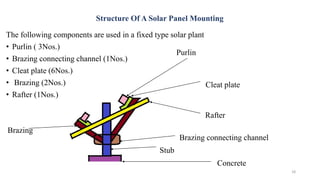

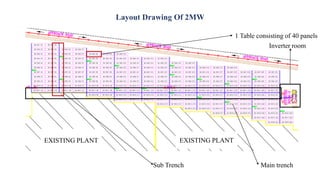

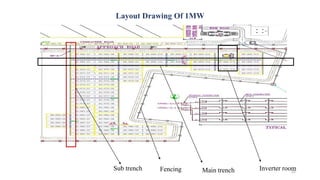

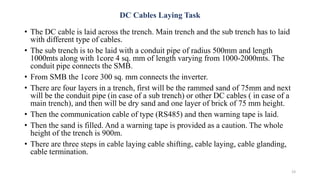

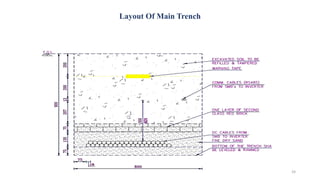

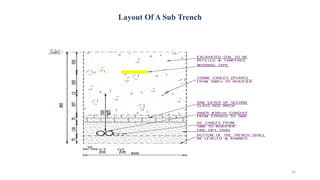

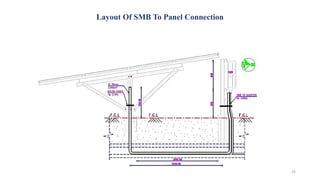

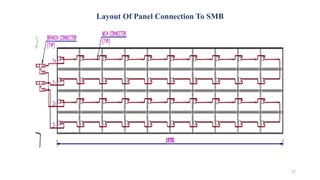

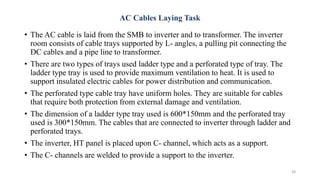

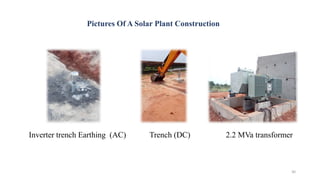

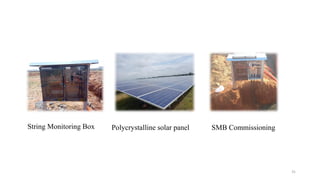

The document details a 3MW solar power plant project in Dindigul, India. It includes construction of 1158 piles for the 2MW section and 570 piles for the 1MW section. A total of 7720 solar panels were installed for the 2MW section and 3800 panels for the 1MW section. The project was completed over 7 months with 51 employees and an investment of 50 lakh rupees. Electrical work included laying DC and AC cables in trenches to connect panels to string monitoring boxes, inverters, and transformers to distribute the power generated.