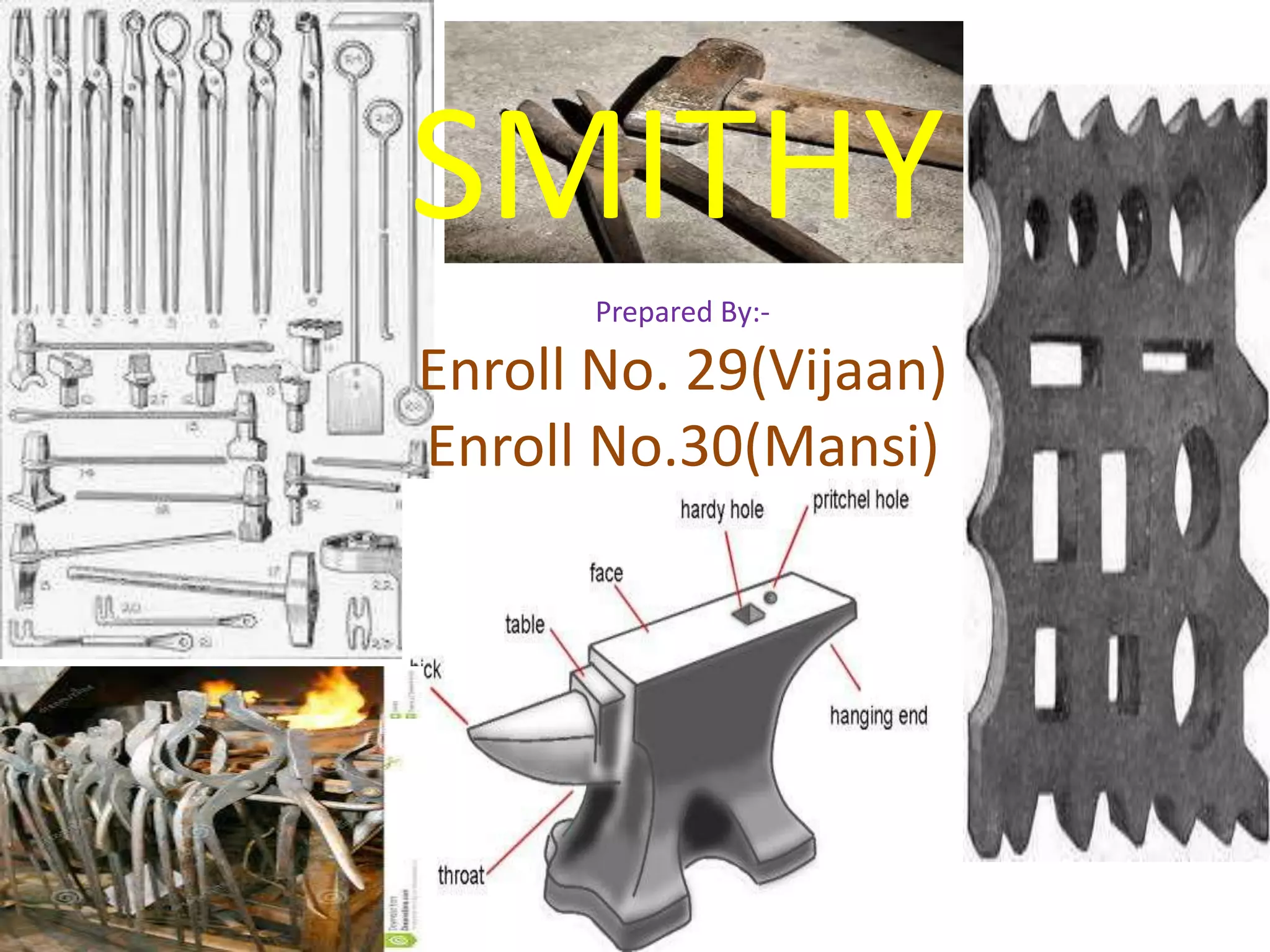

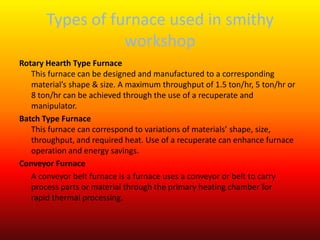

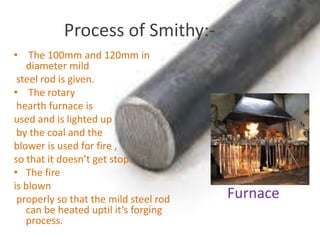

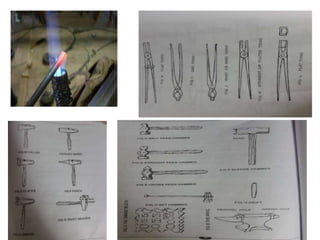

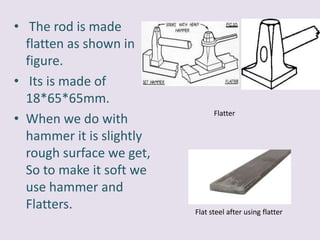

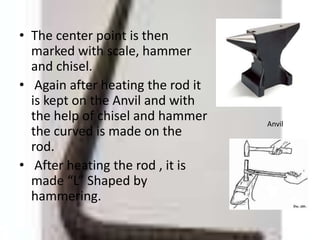

The document discusses smithy work and the smithing process. It describes three types of furnaces used - rotary hearth, batch, and conveyor furnaces. It then outlines the steps to convert a mild steel rod into an L-shape through heating, hammering, and cutting processes. Key steps include heating the rod in a rotary hearth furnace, hammering it while hot to flatten it, using a chisel and hammer to cut it to size, and hammering curves and angles into it. The total estimated cost for converting 0.5kg of mild steel rod into an L-shape at the smithy shop is approximately 68 rupees.