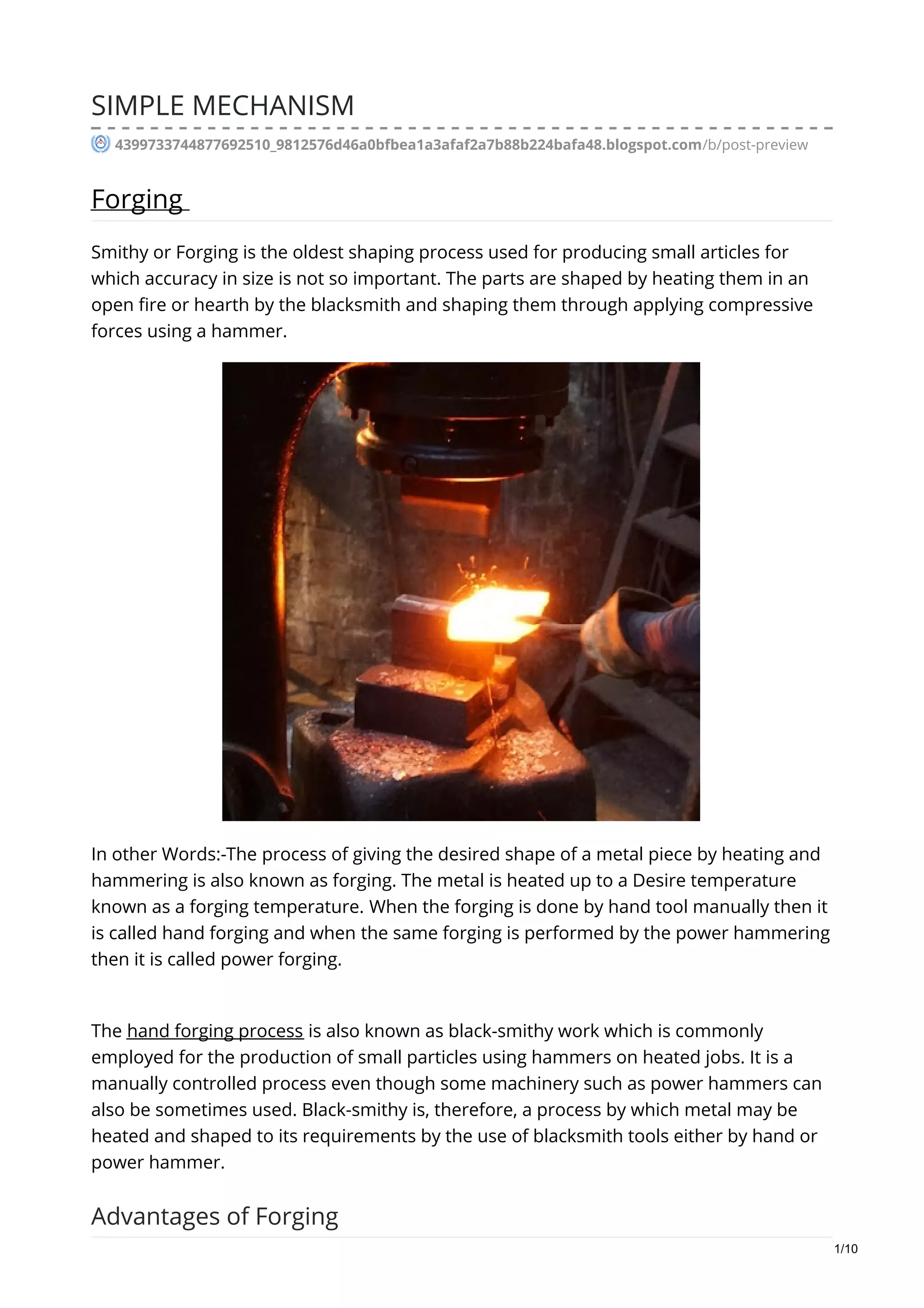

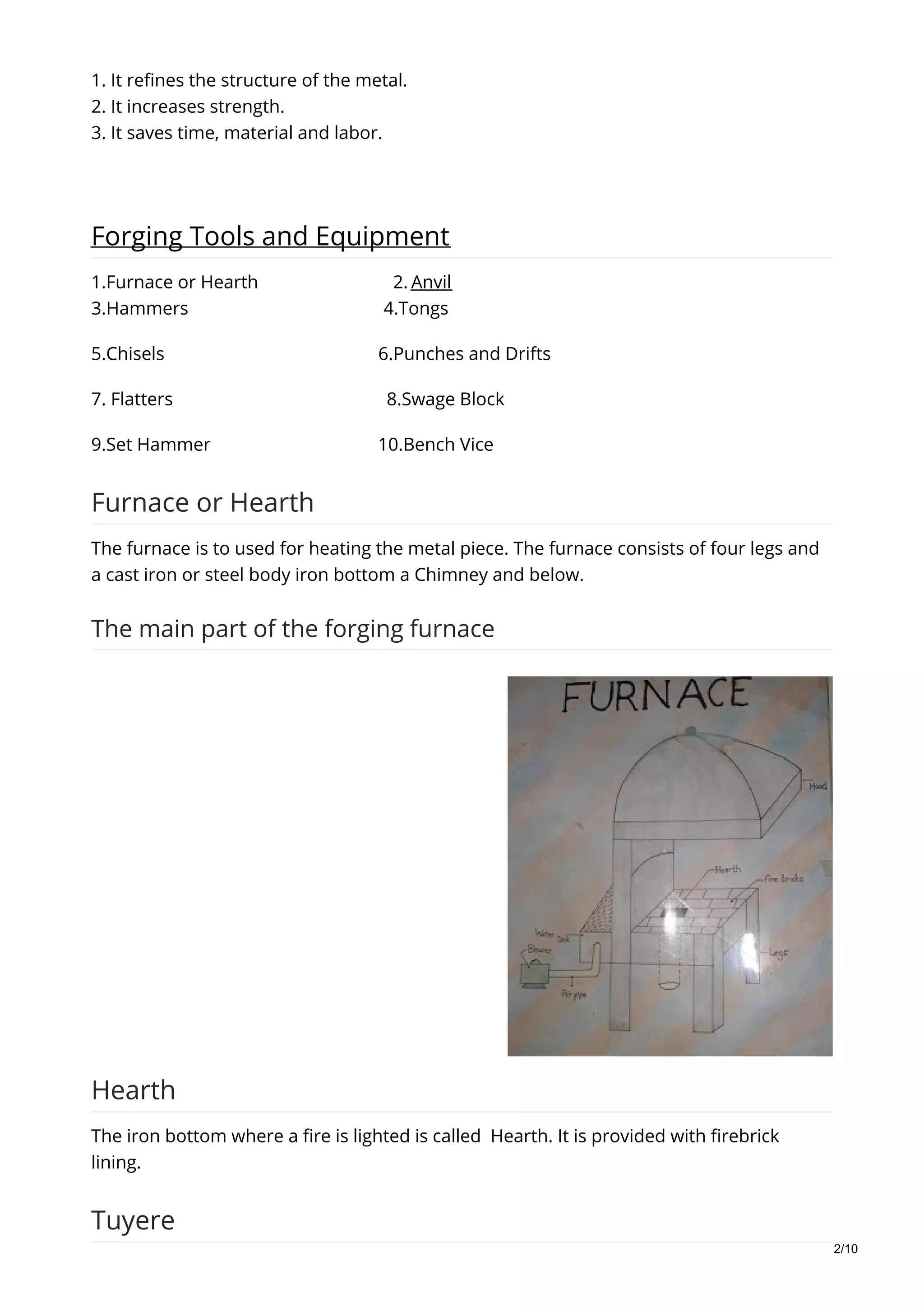

Forging is a traditional metal shaping process that involves heating and hammering to shape metal pieces, typically done by blacksmiths. The document discusses the advantages of forging, tools and equipment required, including furnaces, hammers, tongs, and chisels, as well as the techniques involved in using these tools. It also explains various types of chisels and hammers used in forging processes.