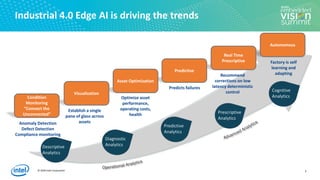

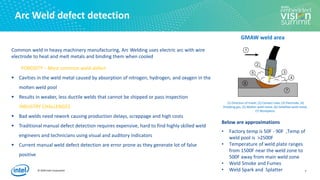

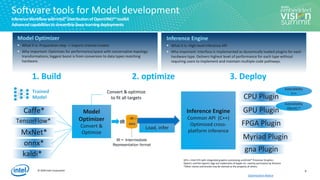

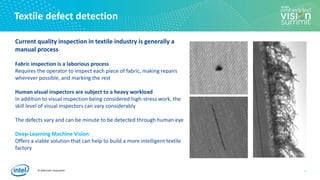

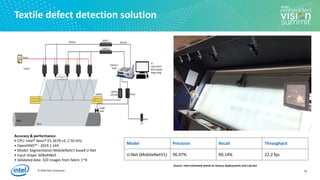

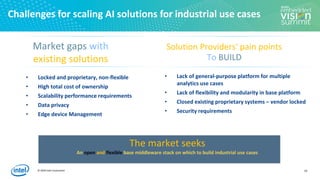

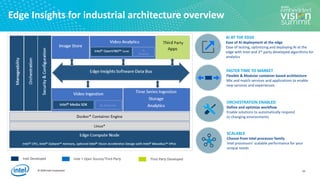

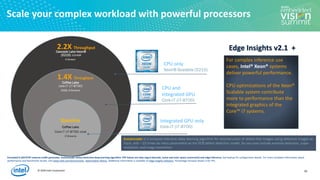

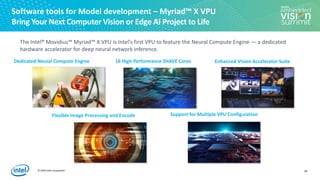

The document discusses Intel's deep learning-based machine vision solutions for smart manufacturing, focusing on applications such as predictive maintenance, quality assurance, and real-time monitoring in various industrial contexts. It highlights the advantages of using Intel's technologies for improving product quality, operational efficiency, and reducing costs via automated defect detection and analytics. Additionally, it addresses challenges in scaling AI solutions and emphasizes the need for flexible, open platforms to optimize industrial workflows.